Intelligent multifunctional overhead contact system operation tower wagon

A catenary, multi-functional technology, applied in the direction of ladders, transport passenger cars, railway car body parts, etc., can solve the problems of troublesome height adjustable structures, affecting construction progress, heavy weight, etc., to reduce procurement and operating costs, reduce labor Strength, the effect of enhancing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

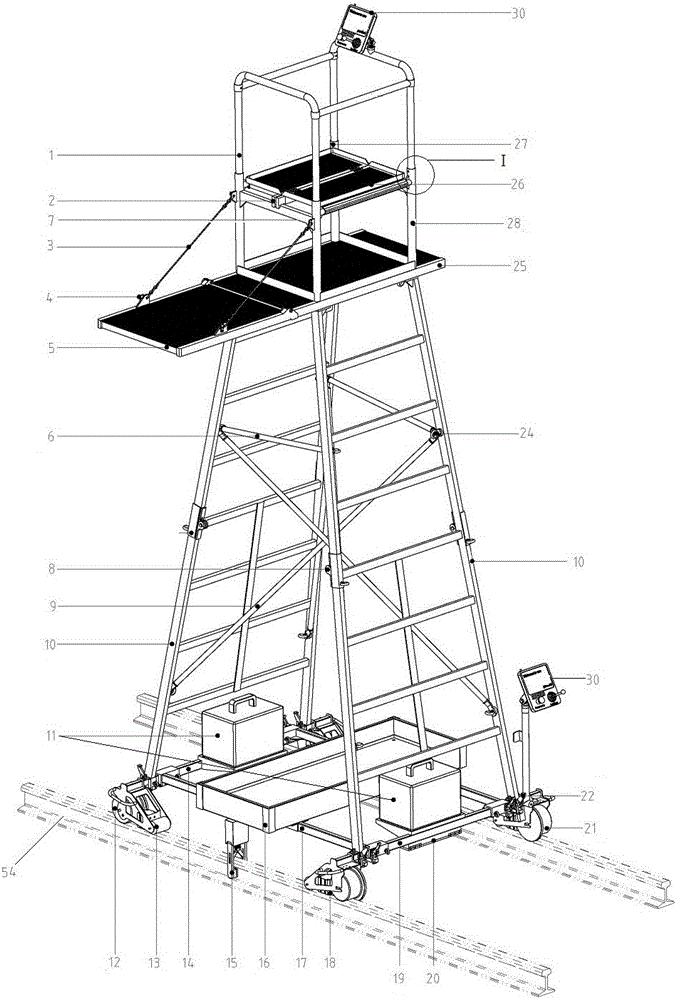

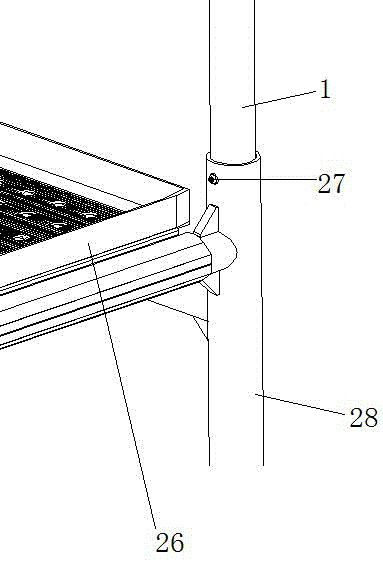

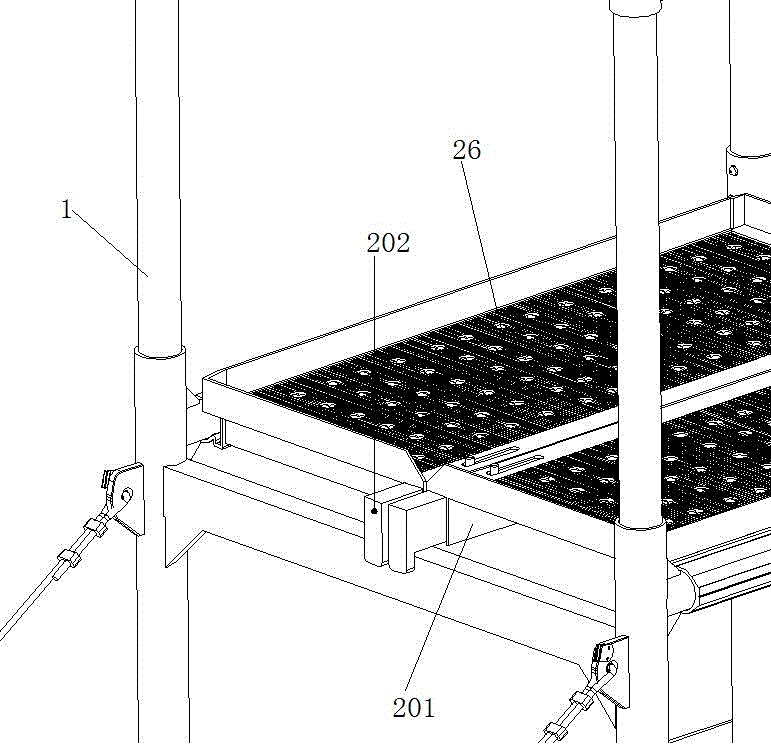

[0052] Such as Figure 1~6 As shown, an intelligent multifunctional catenary work ladder car includes a chassis 51, a car ladder 52 installed on the chassis 51, and a working platform 53 installed on the top of the car ladder 52.

[0053] The chassis 51 includes a chassis longitudinal beam 17 arranged parallel to the track 54 , and a chassis cross member perpendicular to the track and connected to the chassis longitudinal beam. The two ends of the chassis beam 19 at the front end are respectively provided with motor wheels 21 , and the two ends of the chassis beam 14 at the rear end are respectively provided with driven wheels 12 , and the motor wheels 21 are electrically connected with the battery pack 11 . Both the motor wheel 21 and the driven wheel 12 can roll freely on the track 54 . Both the motor wheel 21 and the driven wheel 12 are connected with an auxiliary bearing wheel 13 .

[0054] The lower end of the car ladder 52 is detachably connected to the chassis beam. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com