Biological 3D printing apparatus

A 3D printing and bioprinting technology, applied in metal processing equipment, 3D object support structures, processing and manufacturing, etc., can solve the problems of minimally invasive surgery for tissues and organs that are not applicable, and achieve a wide range of applications, fast curing speed, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

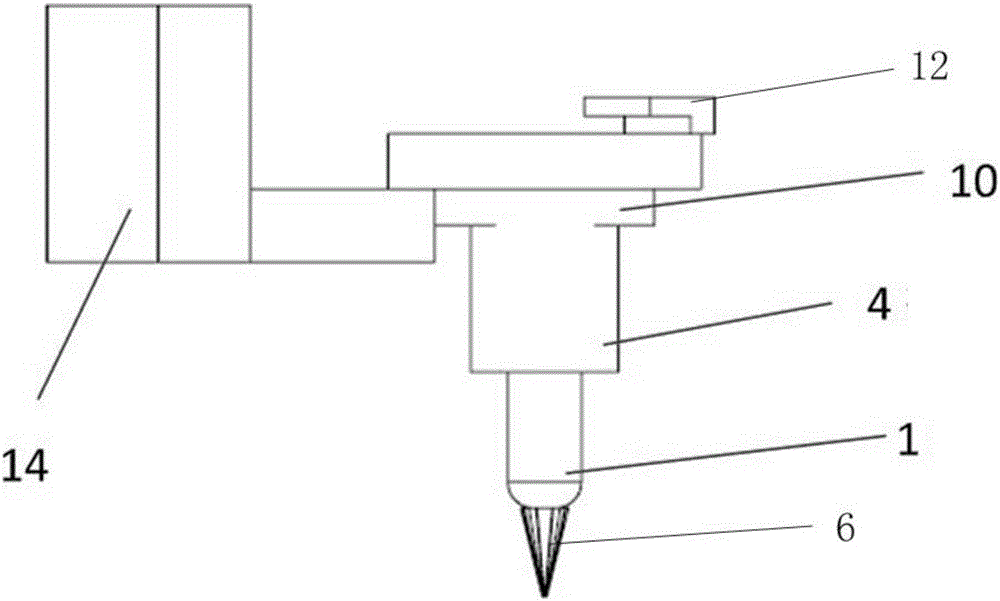

[0036] Such as Figure 1-Figure 3 , This equipment includes printing pen 1, air pump 2, air pressure controller 3, 3D bioprinting pen device 4, printing pen head 6, pen body casing 7, nozzle sleeve 9, connecting piece 10, L-shaped fixing bolt 12, screw hole 13 And printer stand 14;

[0037] The air pump 2, the air pressure controller 3, and the printer frame 14 are connected in sequence. The printer frame is provided with a detachable 3D bioprinting pen device 4, which includes a pen body shell 7 and a pen body shell 7 The printing pen 1 is disassembled. The top of the printing pen 1 is connected to the air pump 2 through a pipe to receive the solution for 3D printing. The bottom end of the printing pen 1 includes a printing pen head 6, and a connecting piece 10 is sleeved on the pen body shell 7. The connecting piece 10 is connected to the printer frame 14 to fix the printing pen 1 on the printer frame 14, wherein the bottom of the pen body shell 7 is provided with a through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com