Preparation method of gas diffusion electrode for electrochemical treatment of SO2

A gas diffusion electrode, SO2 technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problem of inability to meet the requirements of low-concentration sulfur-containing flue gas treatment, restricting the development of electrochemical treatment and industrial applications, mass transfer rate High energy consumption and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

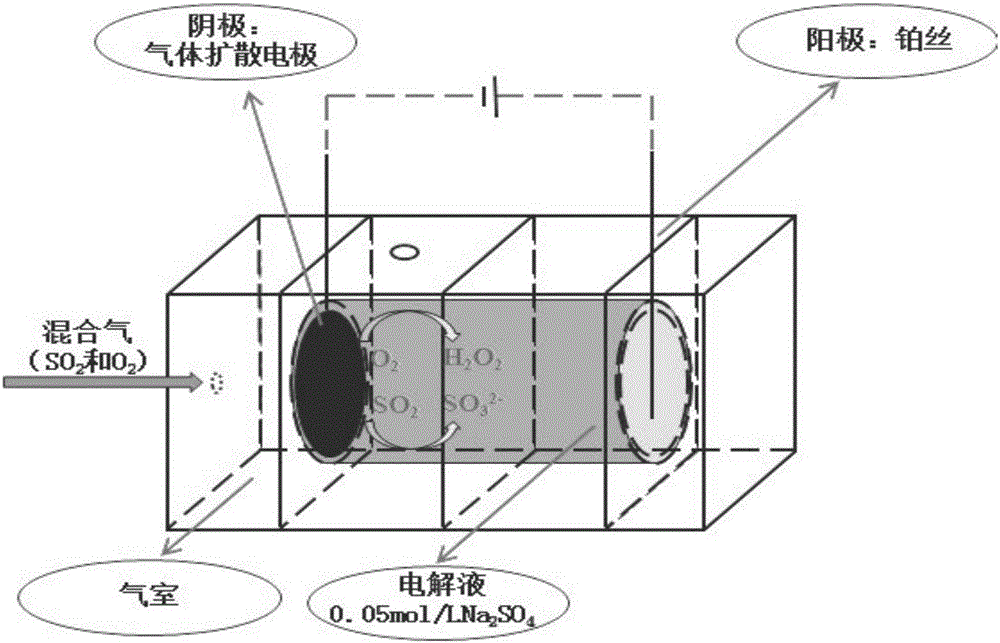

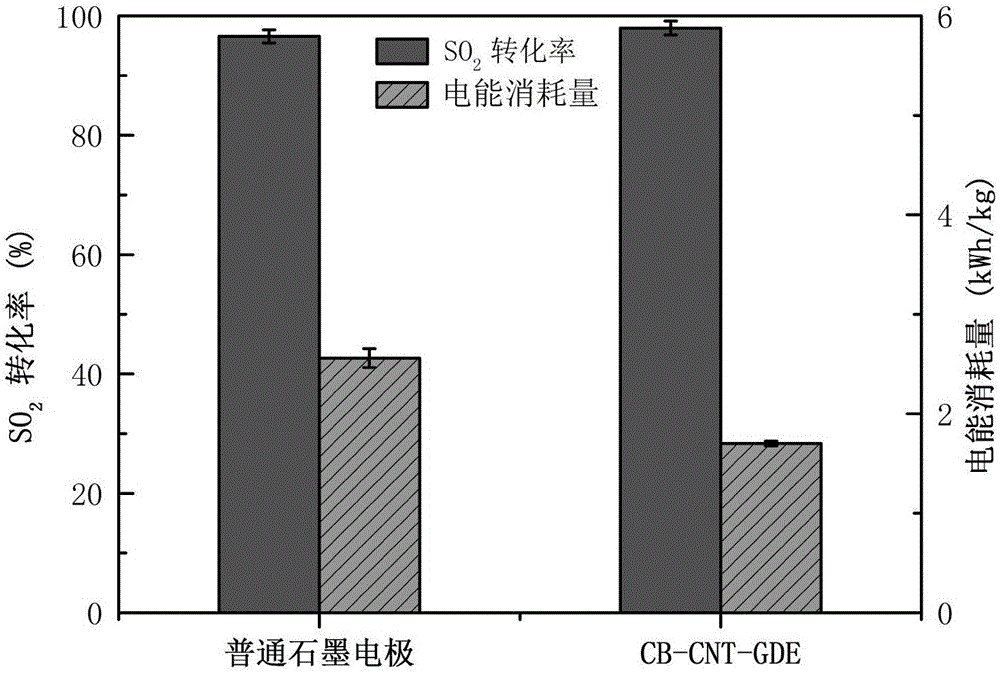

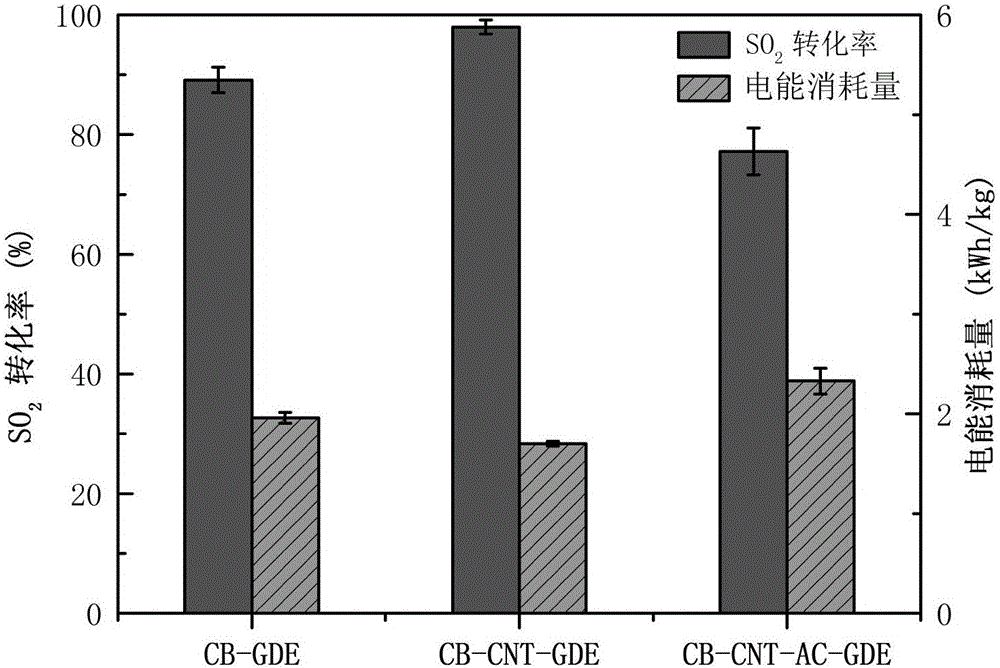

Method used

Image

Examples

Embodiment 1

[0021] An electrochemical treatment of SO 2 The preparation method of the gas diffusion electrode, the steps are as follows:

[0022] 1) Add 2.0g of powdery conductive carbon black to 60mL of absolute ethanol until it is fully submerged and dispersed evenly. After ultrasonic stirring at room temperature for 20min, 5g of polytetrafluoroethylene emulsion with a mass fraction of 60% (density of about 1.45g / mL), continue to ultrasonically stir for 20 minutes, put the obtained mixed solution in an 80°C water bath and stir until it forms a lump, then roll it into a film to obtain a diffusion layer film;

[0023] 2) Cover the diffusion layer film obtained in step 1) on the 60-mesh stainless steel mesh collector fluid, cut it into a circle with a diameter of 6 cm after roll forming, put it into a muffle furnace for calcination at 340°C for 20 minutes, and take it out for use.

[0024] 3) Add 1.9g of powdered carbon black and 0.1g of multi-walled carbon nanotubes to 60mL of absolute ...

Embodiment 2

[0028] An electrochemical treatment of SO 2 The preparation method of the gas diffusion electrode, the steps are as follows:

[0029] 1) Add 2.0g of powdery conductive carbon black to 60mL of absolute ethanol until it is fully submerged and dispersed evenly. After ultrasonic stirring at room temperature for 20min, 5g of polytetrafluoroethylene emulsion with a mass fraction of 60% (density of about 1.45g / mL), continue to ultrasonically stir for 20 minutes, put the obtained mixed solution in an 80°C water bath and stir until it forms a lump, then roll it into a film to obtain a diffusion layer film;

[0030] 2) Cover the diffusion layer film obtained in step 1) on the 60-mesh stainless steel mesh collector fluid, cut it into a circle with a diameter of 6 cm after roll forming, put it into a muffle furnace for calcination at 340°C for 20 minutes, and take it out for use.

[0031] 3) Add 1.9g of powdered carbon black and 0.1g of multi-walled carbon nanotubes to 60mL of absolute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com