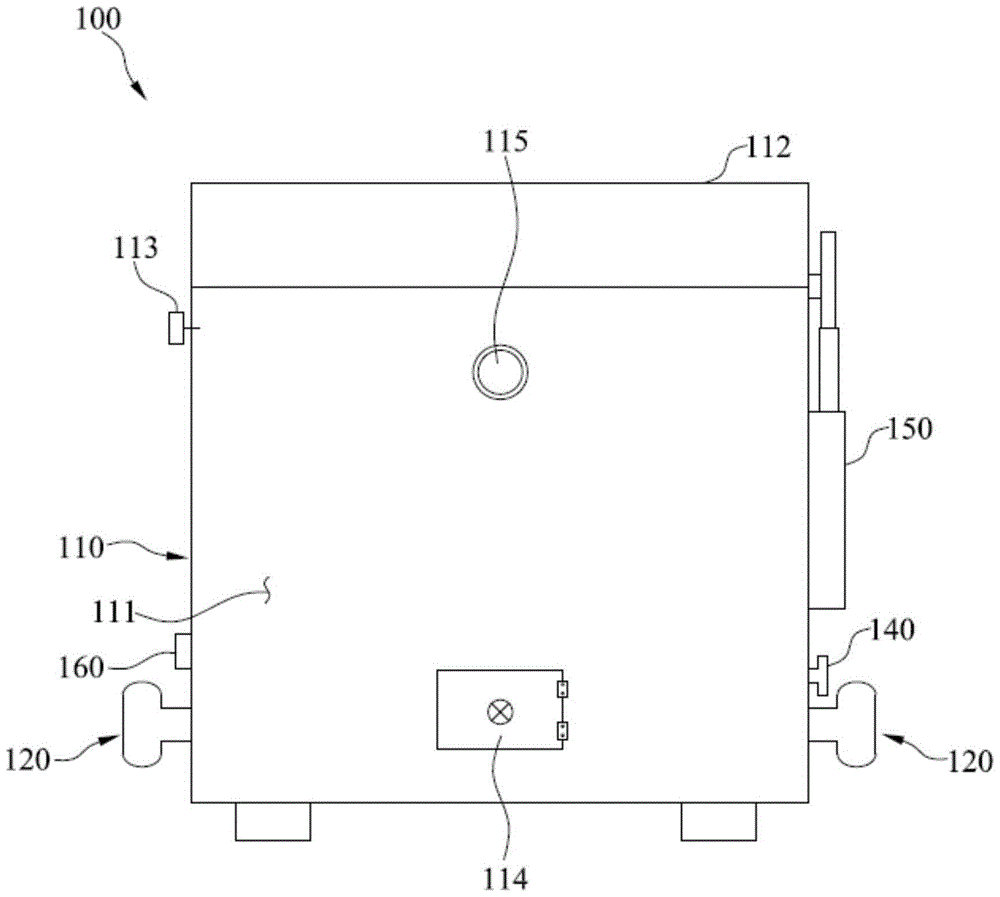

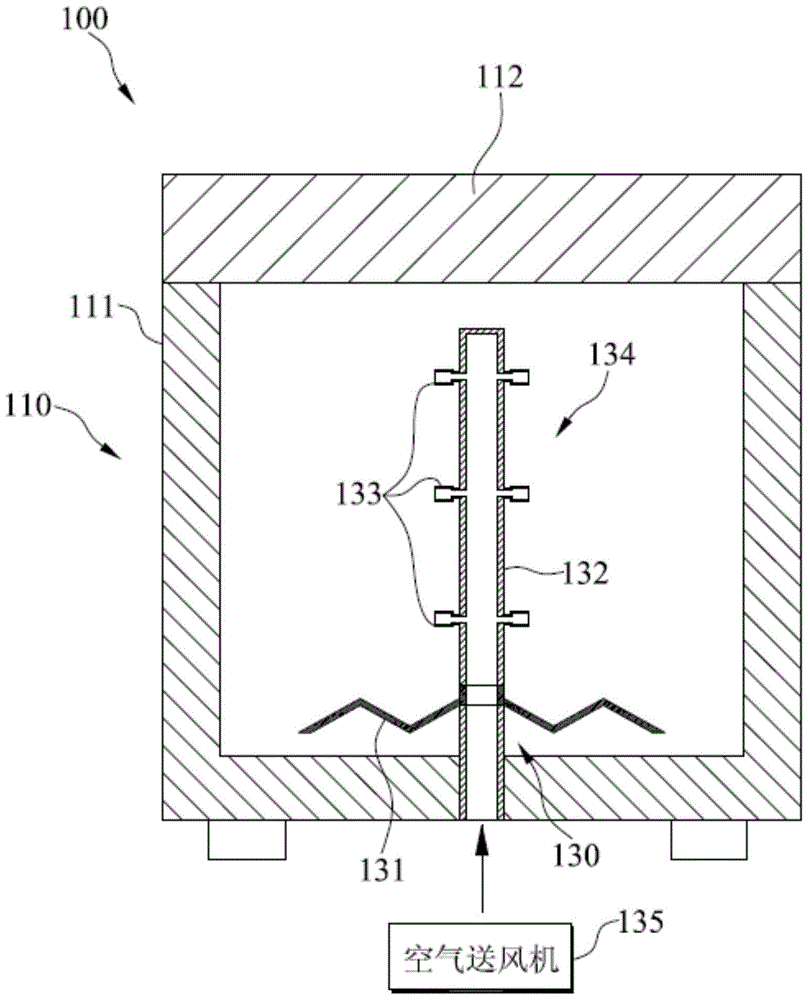

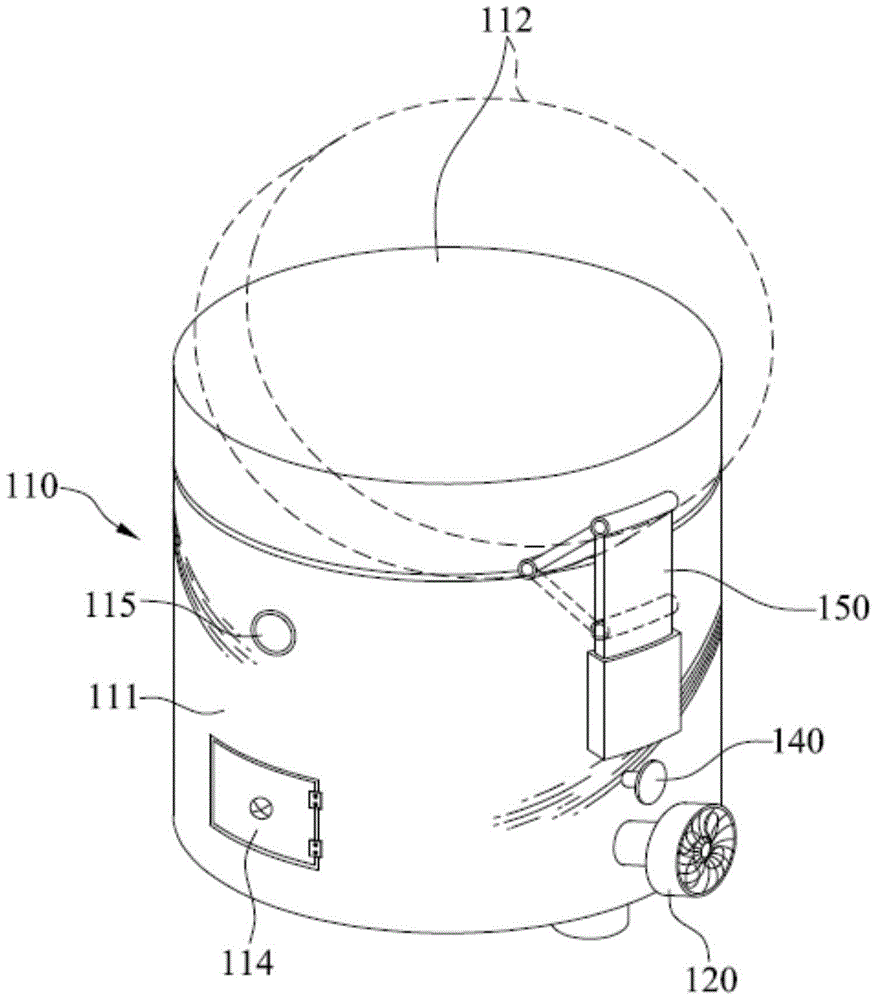

Multi-layer high-temperature pyrolysis incineration apparatus

A high-temperature thermal decomposition and incinerator technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., to achieve the effect of increasing processing capacity and improving processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following describes the present invention in detail in combination with preferred embodiments in order to allow those skilled in the art of the present invention to easily implement it. However, in describing the present invention, if it is considered that related descriptions of well-known structures or functions may obscure the gist of the present invention, the detailed description thereof will be omitted. Also, components having the same or similar functions will be assigned the same figure symbols in all the drawings.

[0062] In addition, in the overall specification, when a certain constituent element is described as being "connected" to other constituent elements, it means not only "directly connected" but also "indirectly connected" via other components. Furthermore, when it is stated that a certain constituent element is "comprised", unless the contrary content is clearly stated, it does not mean that other constituent elements are excluded but that other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com