Simulation method for dynamic simulation of intermediate frequency heat treatment process of longitudinal seam welded pipe

A heat treatment process, straight seam welded pipe technology, applied in the field of induction heat treatment research, can solve the problem of not fully considering the heat conduction at the weld, errors, etc., to achieve the effect of easy mastering and use, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

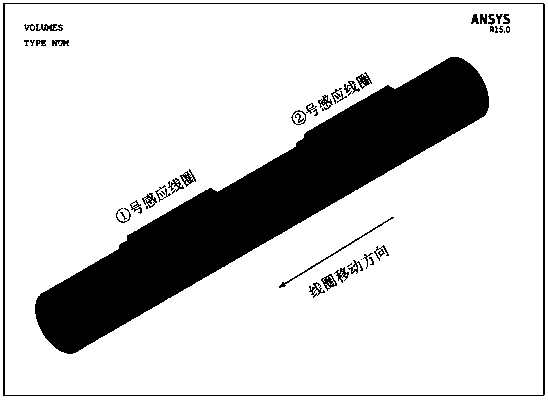

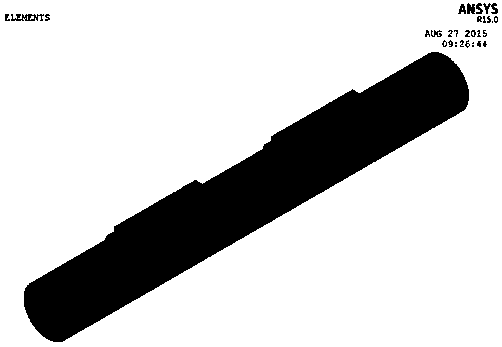

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] The present invention performs dynamic simulation on the intermediate frequency heat treatment process of the straight seam welded pipe, and needs to use the temperature field after high frequency welding as the initial temperature field. First, the temperature load after high-frequency welding is applied to the joints of the entire axial length of the weld model; then, the unit birth and death technology is used to gradually activate some units in the axial direction of the welded pipe to participate in the calculation, and the activated units are selected each time. The distance of each step of the induction coil in the process of electromagnetic-thermal coupling is determined. This method can accurately inherit the temperature field after high-frequency welding to ensure the accuracy of the simulation results.

[0028] Under the premi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com