Measurement rotation acceleration sensor and measurement method

A rotational acceleration and sensor technology, applied in the direction of measurement of acceleration, velocity/acceleration/impact measurement, measuring devices, etc., can solve the problems of low precision, difficulty in accurate measurement of physical quantities, measurement of rotational acceleration of the rotating shaft by the sensor, etc., and achieve the goal of simplifying the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

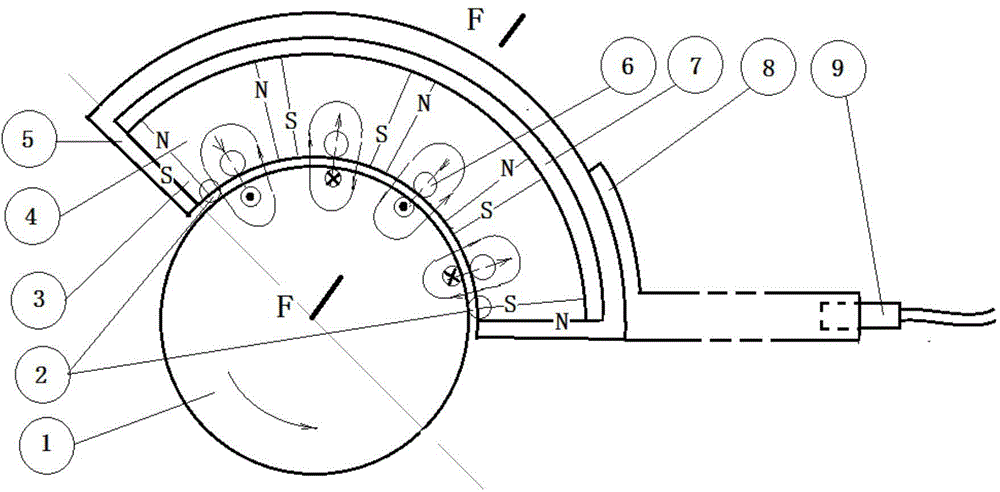

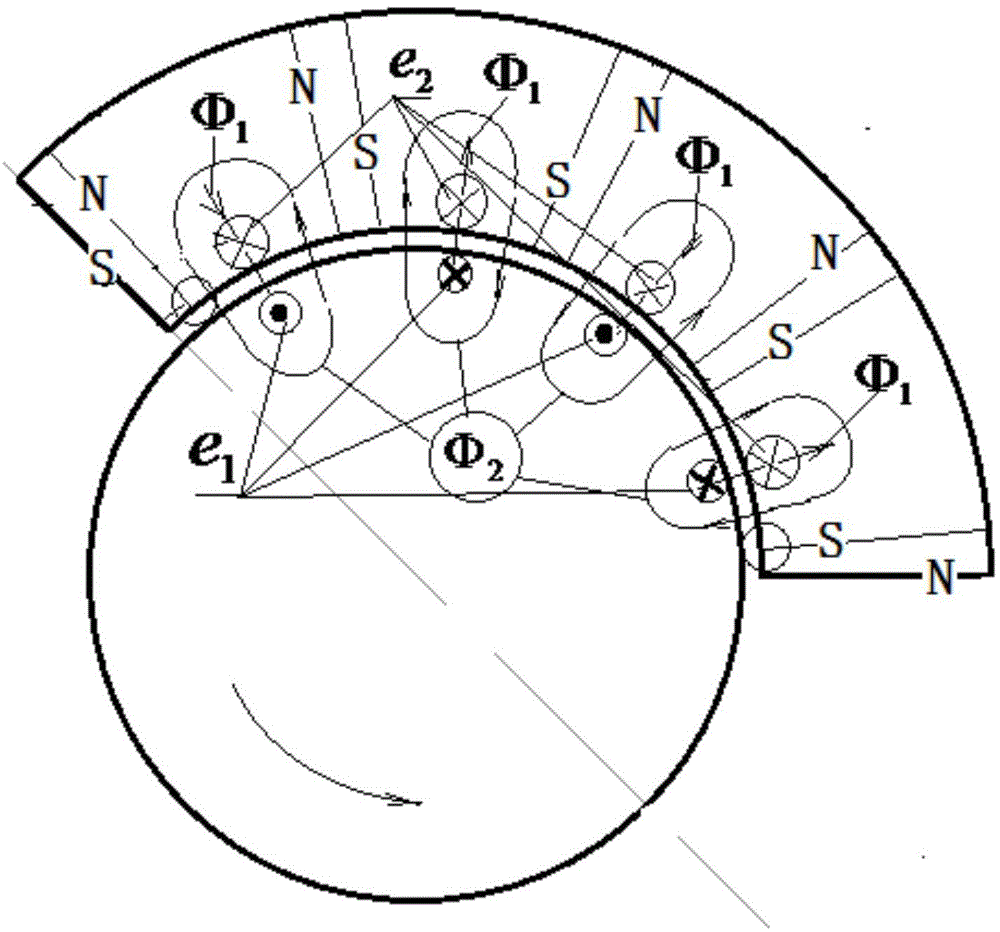

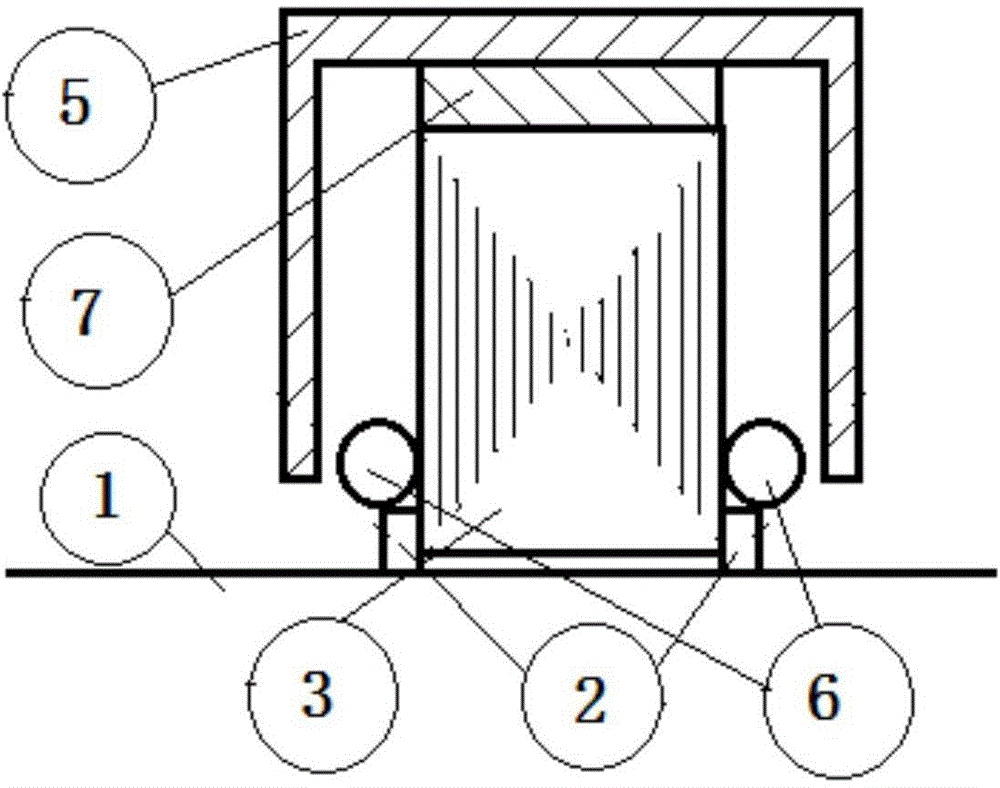

[0022] Such as figure 1 , figure 2 , image 3 As shown, a sensor for measuring rotational acceleration includes a portable part and a rotating part;

[0023] The portable part includes an operating handle 8 , a machine base 5 , an output winding 6 , an elbow gasket 7 , a stator core segment 4 , a permanent magnet 3 , a bearing 2 and an output signal line interface 9 .

[0024] The operating handle 8 is fixedly connected with the machine base 5, and the stator core sections have the same structure, and the stator core sections are spliced to form a fan ring structure, and four bearings 2 are arranged on the inner arc of the fan ring structure. Permanent magnets 3 are arranged between the stator core segments and on the outside of the outermost stator core. The polarities of the adjacent ends of any adjacent permanent magnets are the same. Output windings are arranged in the winding slots of each section of the stator core. The outer arc surface and the outer arc surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com