Pipeline pressure testing system and method

A pipeline pressure test and pipeline technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as pressure exceeding the pressure level, easy safety accidents, pipeline pressure test interference, etc. The effect of reducing equipment cost, improving pressure test accuracy, and improving isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

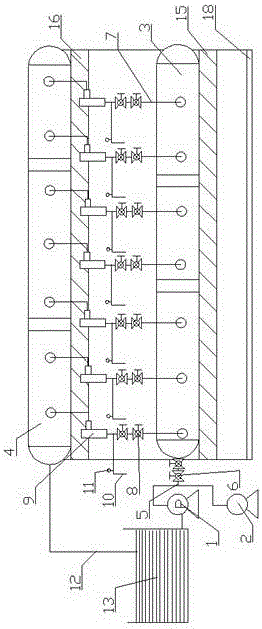

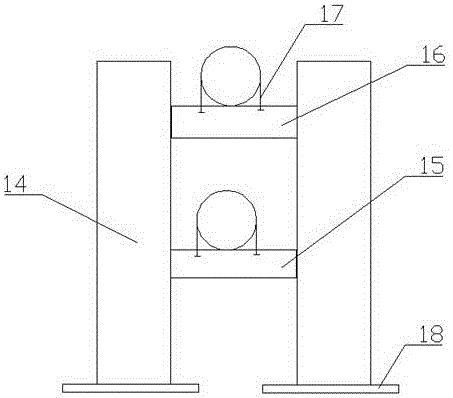

[0043] Such as figure 1 and figure 2 The pipeline pressure test system shown includes an upper water pump 1 , a pressure pump 2 , a pressure-resistant distribution pipe 3 , a pressure test pipeline 10 and a safety valve return pipe 4 . The upper water pump 1 is a centrifugal pump, and multiple pumps can be set according to the number of pressure test pipelines. The upper water pump 1 and the pressing pump 2 are respectively connected to the inlet of the pressure-resistant distribution pipe 3 through the inlet pipe 5, and two control valves 6 are installed on the inlet pipe 5, and the specification of the control valve 6 is DN20PN15. The control valve 6 can conveniently control the water supply and the pressure test, and the isolation of the water supply pump 1 and the pressure pump 2 from the pressure-resistant distribution pipe 3 and the pressure test pipeline 10 is realized by setting two control valves 6 .

[0044] When selecting the pressure-resistant distribution pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com