Tooth joint type outer wall thermal-insulating integrated board provided with antifouling layer

An external wall thermal insulation and integrated board technology, applied in the field of decoration materials, can solve the problems of aging waterproof materials, poor sealing of temperature joints, and water ingress of external walls, etc. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

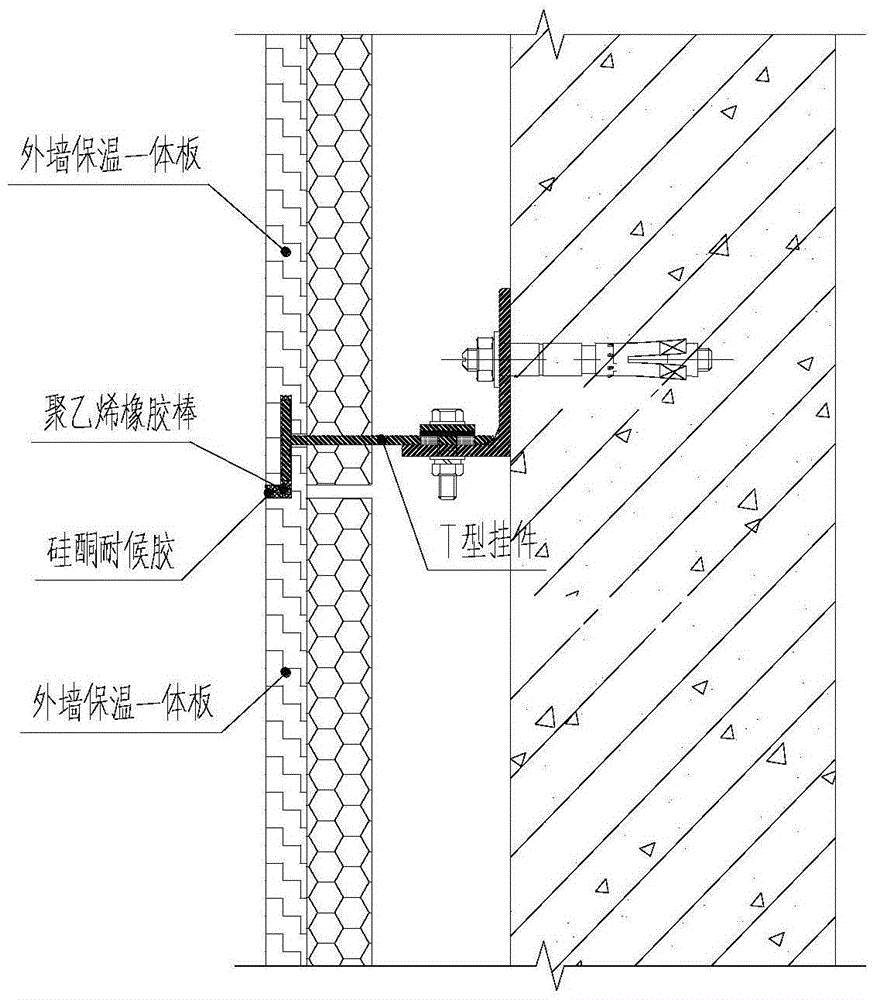

[0018] Such as figure 1 As shown, the present invention provides a tooth-jointed external wall thermal insulation integrated panel provided with an antifouling layer, including an external wall decorative panel and an insulating layer, both of which are square panels and whose length direction is The dimensions in the width direction are consistent; the exterior wall decoration plate is coated with nanocomposite fluorocarbon paint;

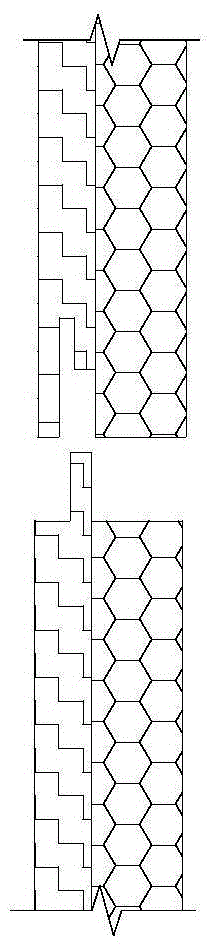

[0019] The exterior wall decoration board and the insulation layer are glued together by silicone weather-resistant adhesive to form a square exterior wall insulation integrated board, such as figure 2 As shown, the four sides of the exterior wall decorative board are provided with connecting teeth or grooves that match the connecting teeth, and the two opposite sides are provided with different connecting structures; ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com