A method and device for improving the ability of diamond-like carbon film to resist laser damage

A diamond film, anti-laser technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of infrared transmittance, refractive index, extinction coefficient of DLC film, etc., to enhance anti-laser Damage ability, increase heat accumulation, simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment:

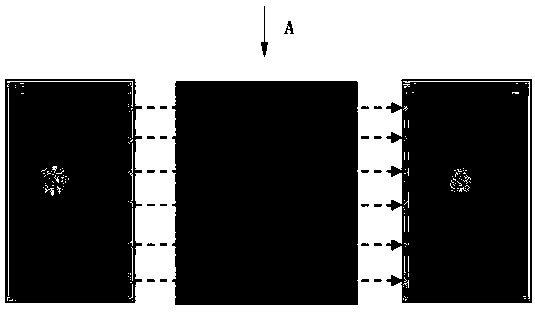

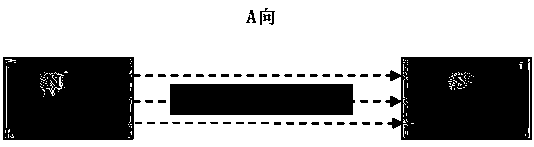

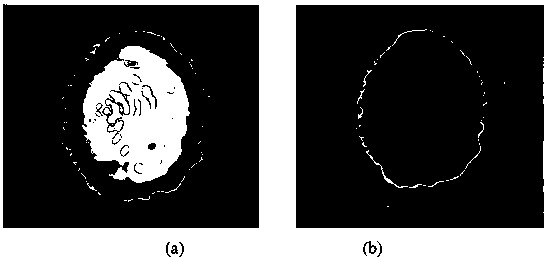

[0032] The invention provides a method for improving the anti-laser damage ability of the diamond-like film, which is to form a magnetic path with a closed loop on the surface of the DLC and the dielectric film, so that the gradient of the magnetic field on the film surface is the largest. Specifically, on the surface of DLC and dielectric film, pig iron material is used as the magnetic medium, and a closed-loop magnetic path is formed with a certain structure to reduce the loss of magnetic flux and maximize the gradient of the magnetic field on the film surface. Use strip-shaped square permanent magnets to keep the strip magnets closely attached to the magnetic end. At the same time, the relationship between the magnetic field and the surface of the film is that there is a relatively parallel displacement on the horizontal plane, that is, the transverse ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com