Method for producing ethanol from turmeric

A technology of ethanol and turmeric, which is applied in the field of ethanol production from turmeric, can solve the problems of low comprehensive utilization rate, waste, and high cost of diosgenin, and achieve the effects of saving costs, improving purity, and reducing heat energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

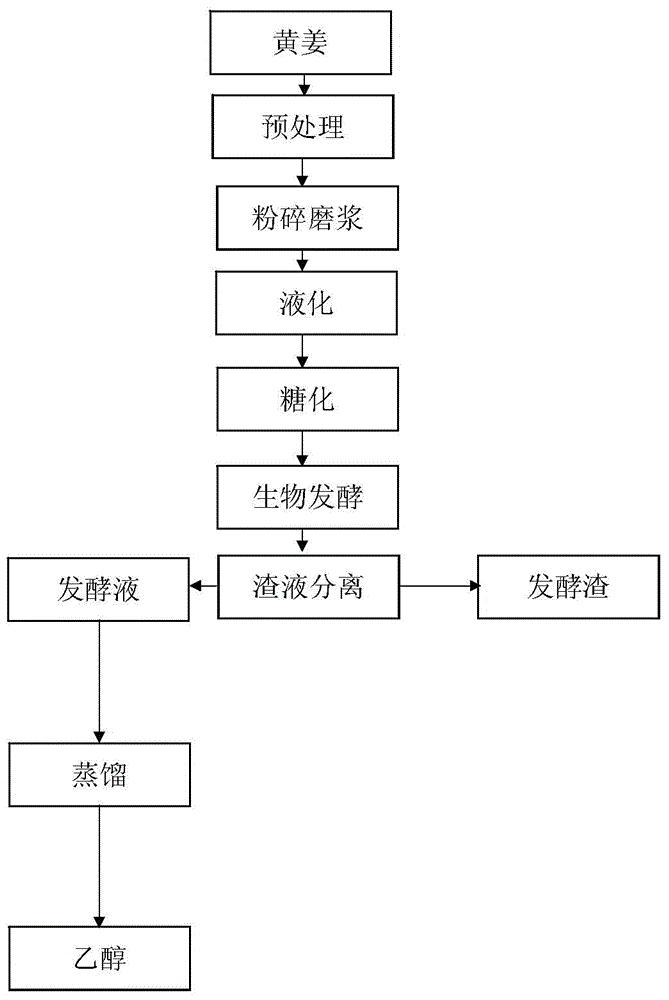

Image

Examples

Embodiment 1

[0048] Wash 2.5 tons of turmeric, remove impurities at the same time, and recycle the washing water after natural precipitation, grind the cleaned and removed turmeric with a pulverizer, add water and grind it into a slurry with a particle size of <2mm, wherein the The solid content is 20% by weight, and the slurry is added to the α-amylase with an activity of 40000u / ml, and the dosage is 10u / g starch, and the starch liquid is obtained by enzymatic hydrolysis and liquefaction. The temperature during enzymatic hydrolysis and liquefaction is controlled at 100°C , the time for enzymatic hydrolysis and liquefaction is 90 minutes, the temperature of the liquefied starch solution is lowered to 60°C, and α-1,4-glucose hydrolase with an activity of 100000u / ml is added to the starch solution for saccharification for 40 minutes to obtain mash, α-1 , The amount of 4-glucose hydrolase is 150u / g starch, and the fermented yeast is added to the saccharification mash for biological fermentatio...

Embodiment 2

[0051] Wash 4 tons of turmeric and remove impurities at the same time. The washing water is recycled after natural precipitation. The turmeric after cleaning and removing impurities is crushed with a pulverizer, and ground with water to form a slurry with a particle size of <1mm. The solid content is 30% by weight, and the slurry is added with β-amylase with an activity of 30000u / ml for enzymatic hydrolysis and liquefaction to obtain starch liquid. The dosage of β-amylase is 12u / g starch, and the temperature during enzymatic hydrolysis and liquefaction is controlled At 85°C, the time for enzymatic hydrolysis and liquefaction is 110 minutes, the temperature of the liquefied starch solution is lowered to 65°C, and β-glucosidase with an activity of 110,000u / ml is added to the starch solution for saccharification for 60 minutes to obtain saccharified mash, β-glucoside The amount of enzyme is 200u / g starch, adding distiller's yeast to the saccharification mash for biological ferment...

Embodiment 3

[0054] Wash 40 tons of fresh turmeric (containing 25% dry matter) turmeric, remove impurities at the same time, and recycle the washing water after natural precipitation, grind the cleaned and removed turmeric with a pulverizer, add water and grind it into a particle size < 1.5mm slurry, wherein the solid content of the slurry is 15% by weight, the slurry is added with an activity of 20000u / ml α-1, 6 bond debranching enzyme for enzymatic hydrolysis and liquefaction to obtain starch liquid, α-1 , the amount of 6-bond debranching enzyme is 8u / g starch, the temperature during enzymatic hydrolysis and liquefaction is controlled at 110°C, the time of enzymatic hydrolysis and liquefaction is 120min, the temperature of the liquefied starch liquid is lowered to 63°C, and activity is added to the starch liquid 120000u / ml of α-1,4-glucose hydrolase was saccharified for 20 minutes to obtain mash, the dosage of α-1,4-glucose hydrolase was 100u / g starch, and Saccharomyces cerevisiae was add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com