High-efficiency coal-to-natural-gas shift process system

A technology of coal-to-natural gas and process system, which is applied in the field of high-efficiency coal-to-natural gas conversion process system, can solve problems such as unreasonable process structure and low efficiency, and achieve the effect of improving overall energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

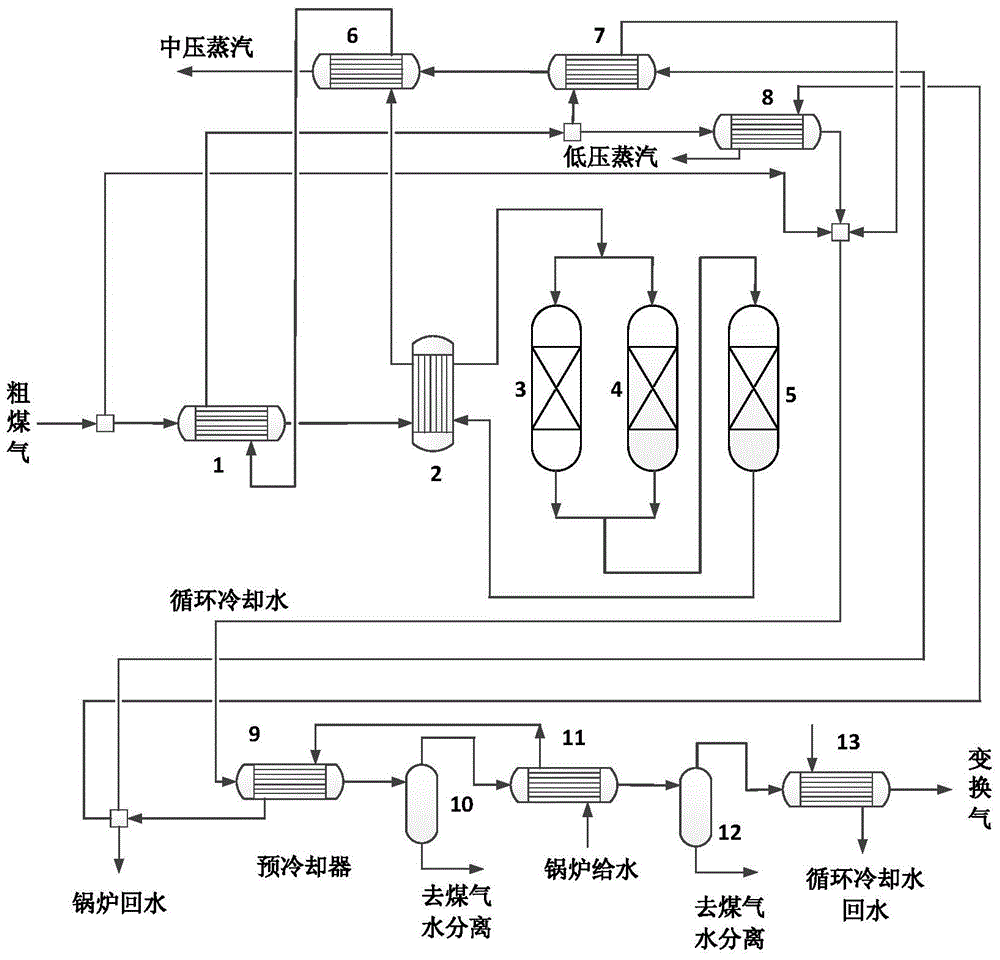

[0035] The system of the high-efficiency coal-to-natural gas conversion process system described in the present invention, such as figure 1 As shown, the system includes a crude gas preheater 1, a gas-gas heat exchanger 2, a pre-converter A3, a pre-converter B4, a main transformer 5, a medium-pressure steam boiler 6, a medium-pressure steam preheater 7, Low-pressure steam boiler 8, precooler 9, flash tank A10, intercooler 11, flash tank B12, final cooler 13.

[0036] According to the methanation plant for H 2 / CO requirements, part of the raw gas from the pressurized gasification device enters the conversion device, and part of the raw gas is directly sent to the mixer through a bypass. The crude gas entering the conversion device first enters the crude gas preheater 1, and after being preheated, the crude gas passes through the gas-gas heat exchanger 2 for heat exchange and enters the pre-converter A3 and pre-converter B4 for conversion reaction, and then enters the main con...

Embodiment 2

[0041] The specific implementation of the high-efficiency coal-to-natural gas conversion process system described in the present invention is as follows:

[0042] Entering the coal-to-natural gas transformation process system with an annual output of 4 billion cubic meters, the single-sequence processing capacity is 140467Nm 3 / h. The crude gas enters the conversion device at a temperature of 170-180°C, first enters the crude gas preheater 1, preheats the crude gas to 200-210°C, passes through the gas-gas heat exchanger 2 to raise the temperature of the crude gas to 305-315°C, and enters the preheater Transformer A3 and pre-shift furnace B4 carry out the shift reaction, the temperature of the shift gas exiting the pre-shift furnace A3 and pre-shift furnace B4 is 340-350°C, and enters the main shift furnace 5 for reaction, and the shift gas after the shift reaction is about 360°C to The gas-gas heat exchanger 2 exchanges heat with the incoming crude gas, and the transformed ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com