PC optical material filtering biological blue light and being halogen-free and flame retarding, and preparation and application thereof

An optical material, blue light technology, applied in the field of high-performance optical materials, can solve problems such as the influence of optical clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

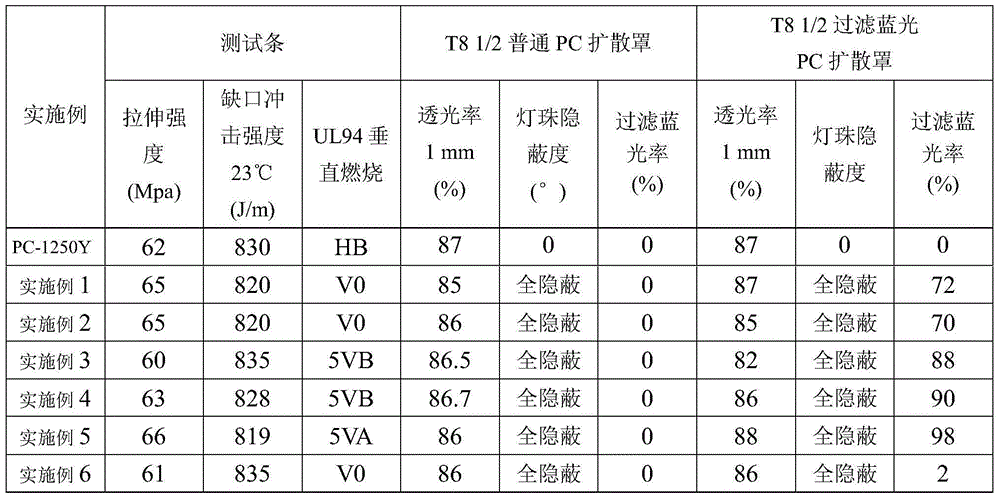

Examples

Embodiment 1

[0072] Example 1: Preparation of a high-performance PC optical material that filters biological blue light and is halogen-free and flame-retardant

[0073] Polycarbonate resin 80% by weight; spherical acrylate resin 10%; spherical silicone resin 1%; styrene-wrapped calcium carbonate 1%; polymer-wrapped inorganic matter 1%; sulfonate flame retardant 0.5%; 0.5% silicon-containing flame retardant; 0.5% phosphorus-based flame retardant; 0.5% sodium antimonate flame retardant; 0.5% zinc borate flame retardant; europium activated yttrium oxide 1%; cerium and terbium activated magnesium aluminate 1%; Fe 2 o 3 0.1%; NiO.Sb 2 o 3 .20TiO 2 0.5%;Cr 2 o 3 .Sb 2 o 3 .20TiO 2 0.02%; Fe 2 o 3 .nH 2 O0.02%; Cr 2 o 30.02%; Ti.Ni.Co.Zn oxide 0.02%; CdS.CdSe0.02%; lubricant 0.8%; light stabilizer 0.3%; phenolic antioxidant 0.2%; phosphite antioxidant 0.1% ; 0.4% acid suppressant, mixed uniformly, transported in a twin-screw extruder, melted and kneaded, extruded and granulated;

...

Embodiment 2

[0075] Example 2: Preparation of a high-performance PC optical material that filters biological blue light and is halogen-free and flame-retardant

[0076] 90% polycarbonate resin by weight; 1% spherical acrylate resin; 0.5% spherical silicone resin; 0.5% styrene-wrapped calcium carbonate; 1% polymer-wrapped inorganic matter; 0.5% sulfonate flame retardant; 0.5% silicon-containing flame retardant; 0.5% phosphorus-based flame retardant; 0.5% sodium antimonate flame retardant; 0.5% zinc borate flame retardant; europium activated yttrium oxide 1%; cerium and terbium activated magnesium aluminate 1%; Fe 2 o 3 0.1%; NiO.Sb 2 o 3 .20TiO 2 0.1%; Cr 2 o 3 .Sb 2 o 3 .20TiO 2 0.1%; Fe 2 o 3 .nH 2 O0.1%; Cr 2 o 3 0.1%; Ti.Ni.Co.Zn oxide 0.1%; CdS.CdSe0.1%; lubricant 0.8%; light stabilizer 0.3%; phenolic antioxidant 0.2%; phosphite antioxidant 0.1% ; mixed with 0.4% acid suppressant, mixed in a medium-speed mixer for 5 minutes; transported in a twin-screw extruder, melted a...

Embodiment 3

[0078] Example 3: Preparation of a high-performance PC optical material that filters biological blue light and is halogen-free and flame-retardant

[0079] 75% polycarbonate resin by weight; 10% spherical acrylate resin; 2% spherical silicone resin; 2% styrene-wrapped calcium carbonate; 2% polymer-wrapped inorganic matter; 1% sulfonate flame retardant; Silicon-containing flame retardant 1%; phosphorus flame retardant 1%; sodium antimonate flame retardant 0.5%; zinc borate flame retardant 0.5%; europium activated yttrium oxide 1%; cerium and terbium activated magnesium aluminate 1%; Fe 2 o 3 0.1%; NiO.Sb 2 o 3 .20TiO 2 0.1%; Cr 2 o 3 .Sb 2 o 3 .20TiO 2 0.1%; Fe 2 o 3 .nH 2 O0.1%; Cr 2 o 3 0.1%; Ti.Ni.Co.Zn oxide 0.1%; CdS.CdSe0.1%; lubricant 0.8%; light stabilizer 0.3%; phenolic antioxidant 0.5%; phosphite antioxidant 0.5% ; mixed with 0.2% acid suppressant, mixed in a medium-speed mixer for 5 minutes; transported in a twin-screw extruder, melted and kneaded to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com