Multi-layer insulation material with heat storage and anti-radiation structure and preparation method thereof

A heat storage material and multi-layer heat preservation technology, applied in the direction of coating, etc., can solve the problems of single heat preservation principle, large volume, and unsatisfactory heat preservation effect, and achieve good heat preservation effect, good heat preservation effect, and comprehensive thermal conductivity improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

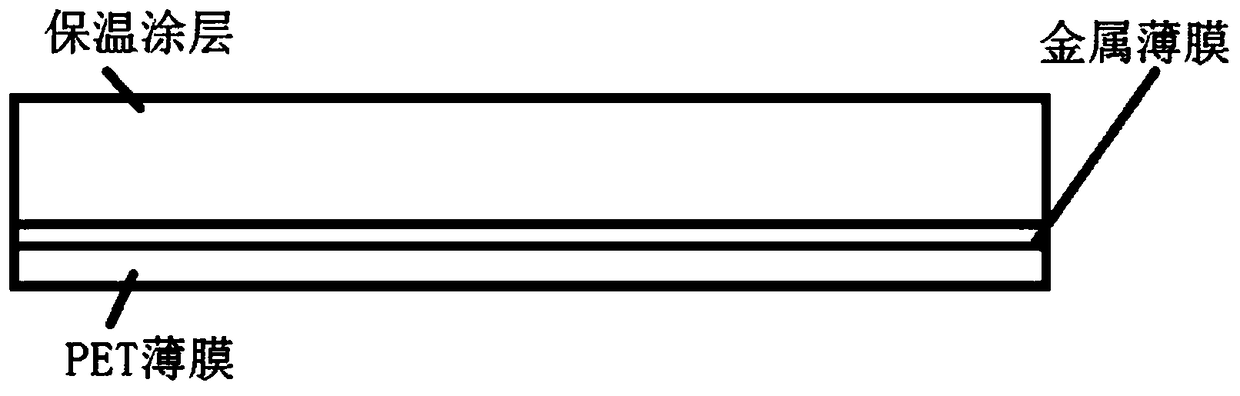

[0032] Use paraffin wax emulsion as heat storage material, add it directly into polymer emulsion to make composite slurry for later use; the amount of paraffin wax emulsion added in the composite slurry is 8wt%; fly ash floating beads are used as hollow material , making a water-soluble slurry after surface treatment, with a solid content of 40%; adding the water-soluble slurry to the composite slurry to obtain a slurry containing fillers and heat storage materials. The obtained slurry is coated on the substrate of single-sided aluminum foil, wherein the thickness of the aluminum film is 10 μm, the thickness of the substrate PET film is 50 μm, and the coating after drying is controlled to be 1mm. The structure is as follows: figure 1 As shown, spare.

Embodiment 2

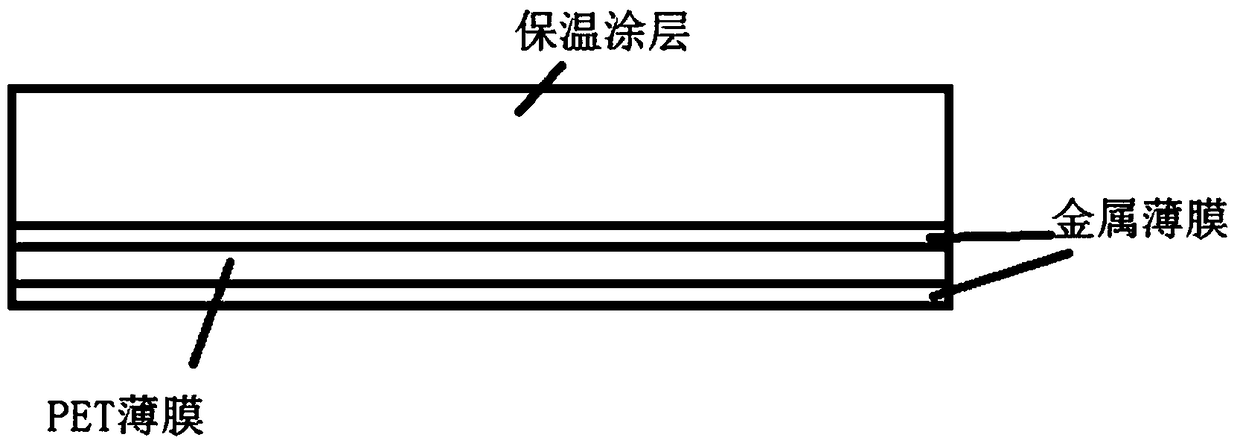

[0034] Use paraffin wax emulsion as heat storage material, add it directly into polymer emulsion to make composite slurry for later use; the amount of paraffin wax emulsion added in the composite slurry is 10wt%; use fly ash floating beads as hollow material , making a water-soluble slurry after surface treatment, with a solid content of 35%; adding the water-soluble slurry to the composite slurry to obtain a slurry containing fillers and heat storage materials. The obtained slurry is coated on the base material of double-sided aluminum foil, wherein the thickness of each layer of aluminum film is 10 μm, the thickness of the substrate PET film is 50 μm, and the coating after drying is controlled to be 1mm. The structure is as follows: figure 2 As shown, spare.

Embodiment 3

[0036] Use paraffin wax emulsion as heat storage material, add it directly into polymer emulsion to make composite slurry for later use; the amount of paraffin wax emulsion added in the composite slurry is 10wt%; use fly ash floating beads as hollow material , making a water-soluble slurry after surface treatment, with a solid content of 35%; adding the water-soluble slurry to the composite slurry to obtain a slurry containing fillers and heat storage materials. The resulting slurry is coated on a single-sided aluminum foil substrate, wherein the thickness of the aluminum film is 10 μm, the thickness of the substrate PET film is 50 μm, and the coating after drying is controlled to be 3 mm. The structure is as follows: figure 1 As shown, spare.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com