A method of constructing a super-hydrophilic anti-reflection damp-proof composite film on a glass substrate

A technology of glass substrate and composite thin film, which is applied in the field of nanomaterial preparation, can solve the problems of losing superhydrophilic ability, superhydrophilic performance is not maintained for a long time, and superhydrophilic self-cleaning cannot be realized, so as to achieve good mechanical properties, The effect of good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of sol solution containing silica hollow sphere nanoparticles:

[0038] 0.1 gram, 0.3 gram and 0.7 gram of polyacrylic acid were dissolved in 4.5 milliliters of ammonia water (the concentration of polyacrylic acid in ammonia water was 30 wt %), and ultrasonically dispersed for 10 minutes; In the container, stirred for 15 minutes to obtain a mixed solution; 1.5 milliliters to 2.5 milliliters of tetraethoxysilane was added dropwise to the mixed solution at a rate of 45 microliters per minute; °C) was stirred for 10 hours to obtain a sol solution containing silica hollow sphere nanoparticles.

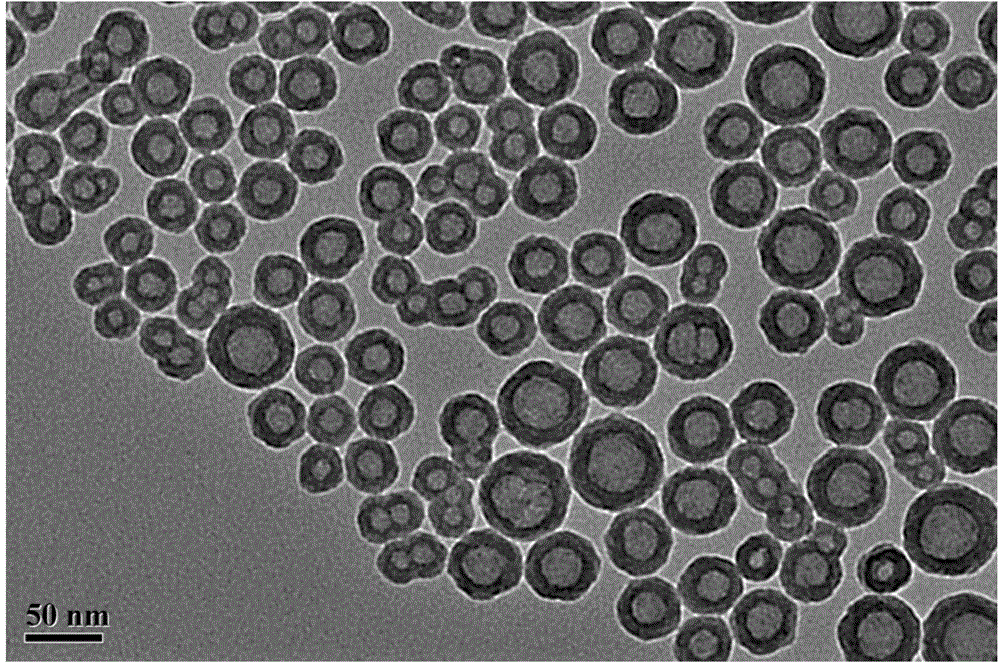

[0039] When the quality of polyacrylic acid was 0.1 gram, 0.3 gram and 0.7 gram respectively, the average particle diameters of the silica hollow sphere nanoparticles in the sol solution of prepared silica hollow sphere nanoparticles were 36 nanometers and 42 nanometers respectively. and 93 nm.

Embodiment 2

[0041] Dissolve 0.2 gram to 0.4 gram of polyacrylic acid in 4.5 milliliters of ammonia water (the concentration of polyacrylic acid in ammonia water is 30 wt %), and ultrasonically disperse it for 10 minutes; then add it dropwise into a container equipped with 90 milliliters of absolute ethanol, stir Obtain mixed solution in 15 minutes; The tetraethoxysilane of 1 milliliter, 2 milliliters and 4 milliliters is added drop-wise in the above-mentioned mixed solution with the speed of 45 microliters per minute respectively; After dropping, gained solution is at room temperature (25 °C) was stirred for 10 hours to obtain a sol solution containing silica hollow sphere nanoparticles.

[0042] When the volume of tetraethoxysilane was 1 milliliter, 2 milliliters and 4 milliliters respectively, the average particle diameter of the silica hollow sphere nanoparticles in the sol solution of prepared silica hollow sphere nanoparticles was respectively 40 nanometers , 45nm and 55nm.

Embodiment 3

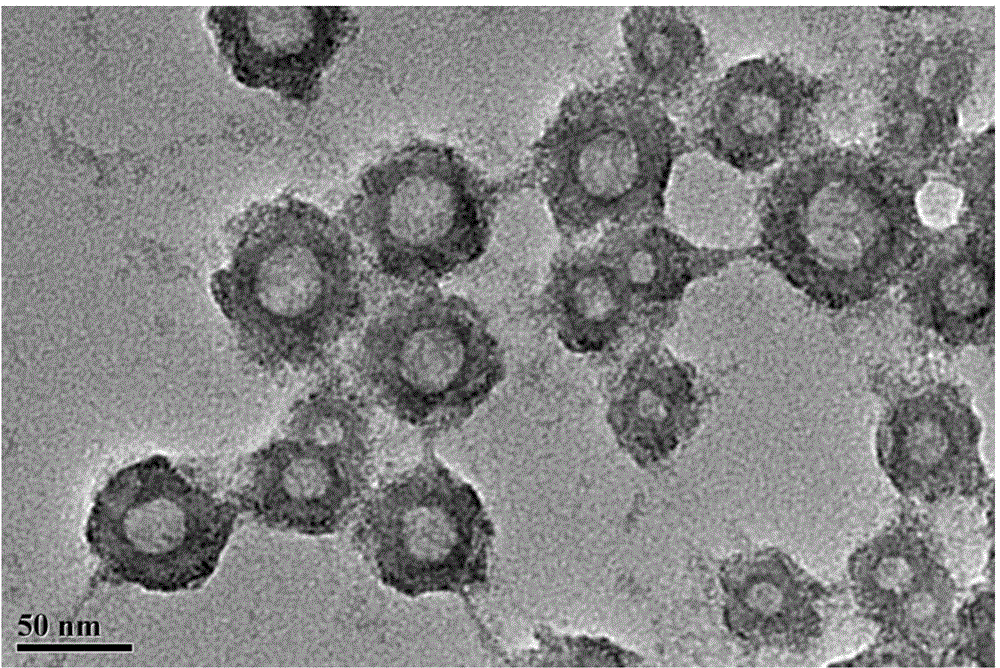

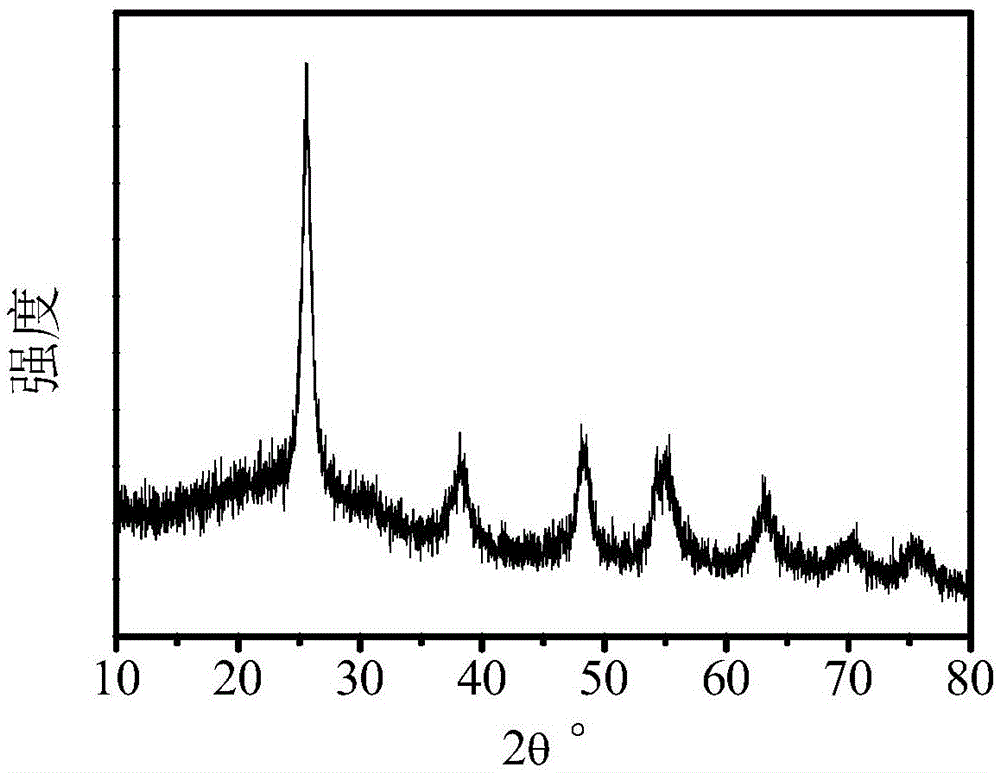

[0044] Preparation of sol solution containing hollow spherical nanoparticles with silica / titania double-layer structure:

[0045] (1) Preparation of a sol solution containing silica hollow sphere nanoparticles: 0.2 gram to 0.4 gram of polyacrylic acid is dissolved in 4.5 milliliters of ammonia (the concentration of polyacrylic acid in ammonia water is 30 wt %), ultrasonic dispersion (general ultrasonic dispersion The time is about 10 minutes); then dropwise added to the container loaded with 90 milliliters of absolute ethanol, stirring (general stirring time is about 15 minutes) to obtain a mixed solution; 1.5 milliliters to 2.5 milliliters of tetraethoxy Silane was added dropwise to the mixed solution at a rate of 45 microliters per minute; after the dropwise addition, the resulting solution was stirred at room temperature (25°C) (generally, the stirring time was about 10 hours), and a hollow compound containing silica was obtained. Colloidal solution of spherical nanoparticl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com