Clamp for preparing dental micro-tensile specimen and process for clamp

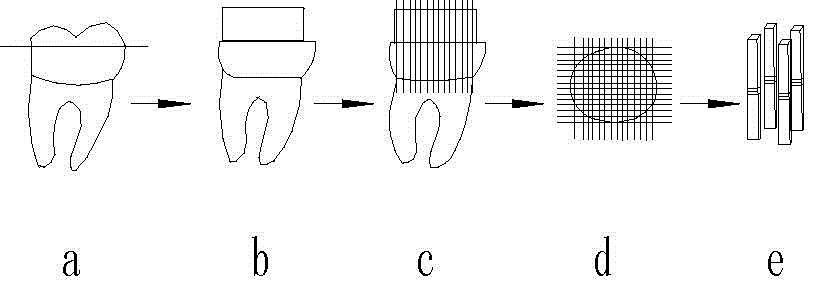

A micro-stretching and test piece technology, applied in the preparation of test samples, manufacturing tools, grinding workpiece supports, etc., can solve the problems such as vibration can not be effectively eliminated, interface damage, affecting the success rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

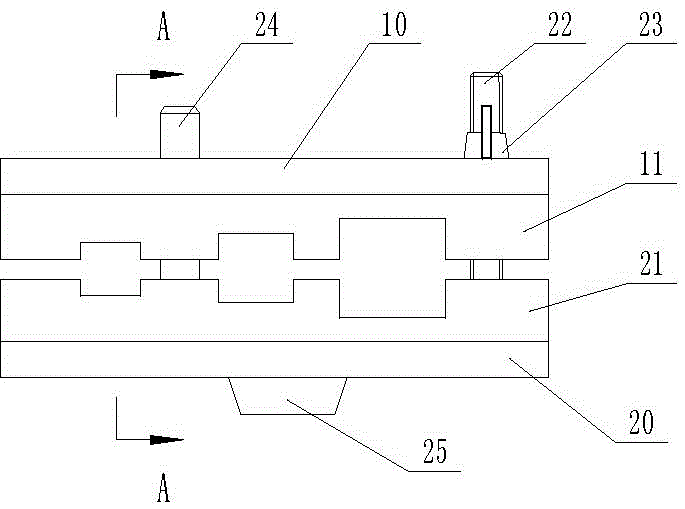

[0034] Embodiment one is basically as figure 2 and image 3 Shown: a jig for preparing a dental micro-tensile specimen, including an upper splint 10 and a lower splint 20 . The upper splint 10 and the lower splint 20 are connected by bolts 22, the bolts 22 are welded on the lower splint 20, the bolts 22 are covered with wing nuts 23, and the upper part of the lower splint 20 is also welded with a guide post 24, the cross-sectional shape of the guide post 24 can be Be triangle, quadrilateral, pentagon, hexagon etc., the present embodiment selects regular quadrilateral for use. The bottom of the lower splint 20 is welded with an inverted tapered positioning block 25 . The upper splint 10 is provided with a connecting hole for the screw to pass through and a guide hole for the guide post 24 to pass through. The inner diameter of the connecting hole is 0.4 mm larger than the outer diameter of the bolt 22 .

[0035] A first elastic block 11 is bonded to the bottom of the upper...

Embodiment 2

[0040] Such as Figure 5 As shown, the difference between the second embodiment and the first embodiment is that the upper splint 10 and the lower splint 20 are fixed by clamps 30 in this embodiment, and the sheet-shaped test piece 40 is immersed in the oil-water mixture at a temperature of 2°C for grinding. . The volume ratio of oil to water in the oil-water mixture is: 1:8.

[0041] This solution adopts the clamp 30 to fix the upper splint 10 and the lower splint 20, which has the characteristics of simple operation and short operation time. Soak the flake test piece 40 in the oil-water mixture at 2°C for grinding. On the one hand, it is to cool down the working surface of the grinding tool and the grinding part of the flake test piece 40, so as to reduce the impact of high temperature caused by grinding on the grinding surface. On the other hand, because the oil film molecules are attached to the surface of the water, the cold water is isolated from the air, prolonging th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com