A supported iron-nickel phosphide catalyst material and its application

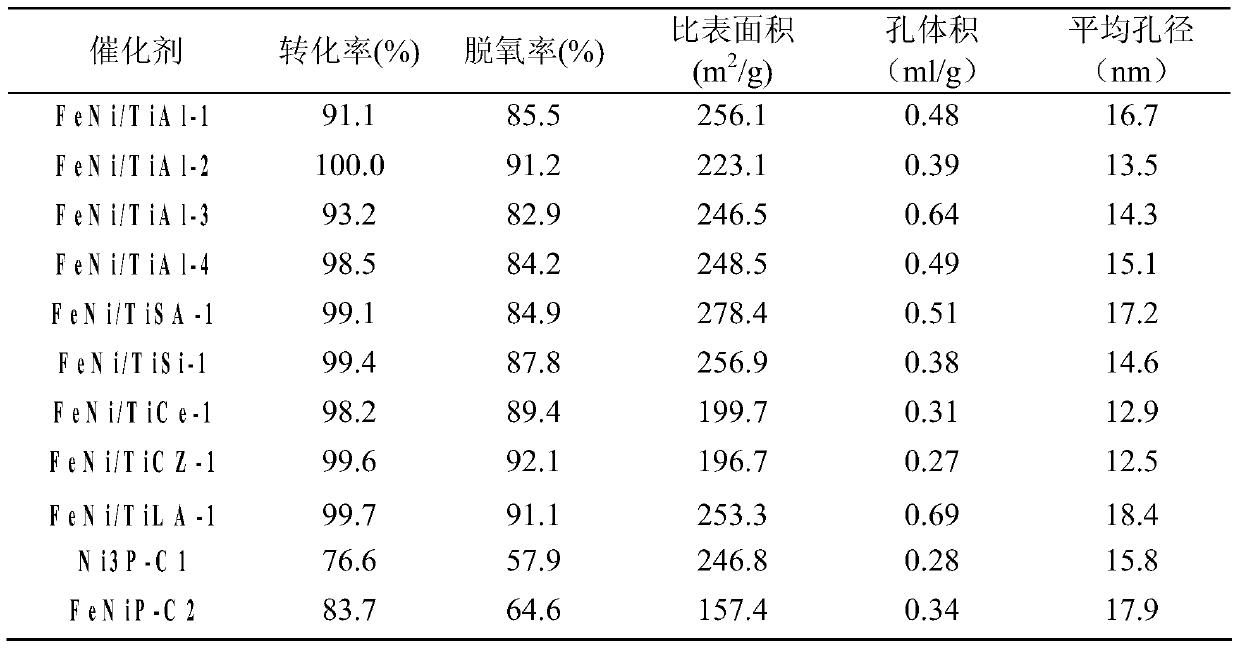

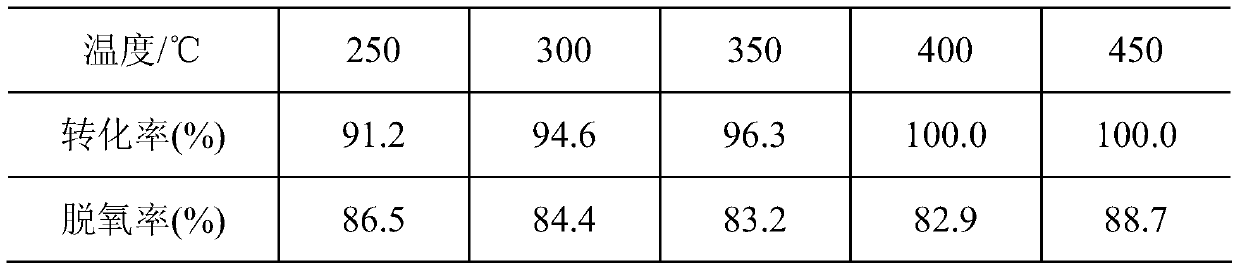

An iron-nickel phosphide, supported technology, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, biological raw materials, etc., can solve the problem of low dispersion of active components and hydrodeoxidation capacity. Weak problems such as high activity and selectivity, large active surface, and enhanced catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare 0.35mol / l butyl titanate solution in absolute ethanol, take 100ml and add 35mmol dodecyldimethyl tertiary amine (DMA12) as template agent, add 35mmol glacial acetic acid while stirring, make it and Butyl titanate forms a chelate. Add 100ml of deionized water to the sol to make the colloidal particles form an open skeleton structure; at the same time, slowly add 57.53g of aluminum isopropoxide, the sol gradually loses its fluidity and forms a gel. The gel was dried at a constant temperature at 100°C for 24 hours to remove moisture, organic groups and organic solvents in the gel. Put the prepared crystal into a muffle furnace and program the temperature to 550°C for 4 hours to obtain TiO 2 -Al 2 o 3 The composite support is denoted as TiAl-1.

Embodiment 2

[0042] Prepare 0.79mol / l butyl titanate solution in absolute ethanol, take 100ml and add 78.8mmol cetyltrimethylammonium bromide (CTAB) as template agent, add 78.8mmol propionic acid while stirring, Make it form a chelate with butyl titanate. Add 100ml of deionized water to the sol to make the colloidal particles form an open skeleton structure; at the same time slowly add 43.33g of aluminum isopropoxide, the sol gradually loses its fluidity and forms a gel. The gel was dried at a constant temperature at 100°C for 24 hours to remove moisture, organic groups and organic solvents in the gel. Put the obtained crystal into a muffle furnace and program the temperature to 500°C for 4 hours to obtain TiO 2 -Al 2 o 3 The composite support is denoted as TiAl-2.

Embodiment 3

[0044] Prepare 0.60mol / l titanium tetrachloride TiCl in absolute ethanol 4 Solution, take 100ml and add 59.9mmol polyvinylpyrrolidone (PVP) as template agent, add 59.9mmol oxalic acid while stirring, make it and TiCl 4 Chelates are formed. Add 100ml deionized water to the sol to make the colloidal particles form an open skeleton structure; meanwhile slowly add 90.79g Al(NO 3 ) 3 9H 2 O, the sol gradually loses its fluidity and forms a gel. The gel was dried at a constant temperature at 100°C for 24 hours to remove moisture, organic groups and organic solvents in the gel. Put the prepared crystal into a muffle furnace and program the temperature to 550°C for 4 hours to obtain TiO 2 -Al 2 o 3 Composite support TiAl-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com