Air filter

An air filter and filter net technology, applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve problems such as difficult to supply users with clean air, affect the filtration efficiency of harmful substances, and affect the comfort of users, etc., to achieve Easy assembly and disassembly, good airtightness and smooth flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

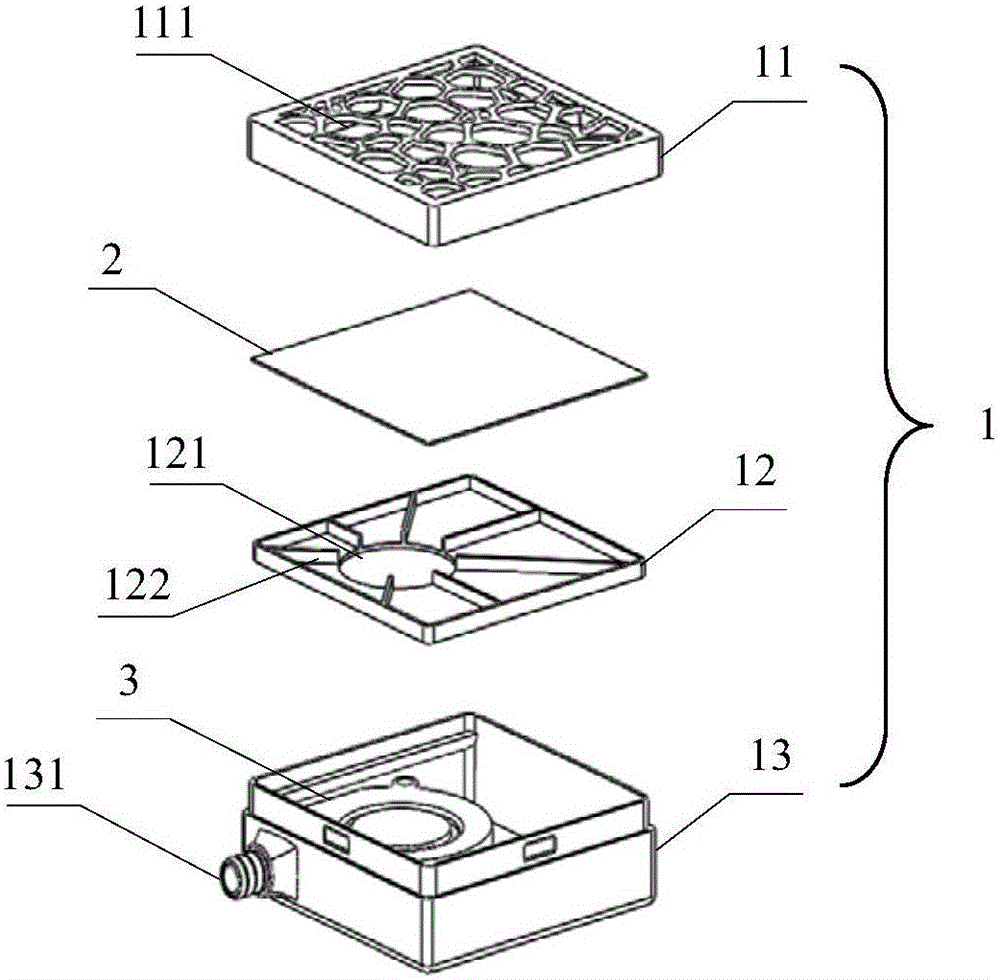

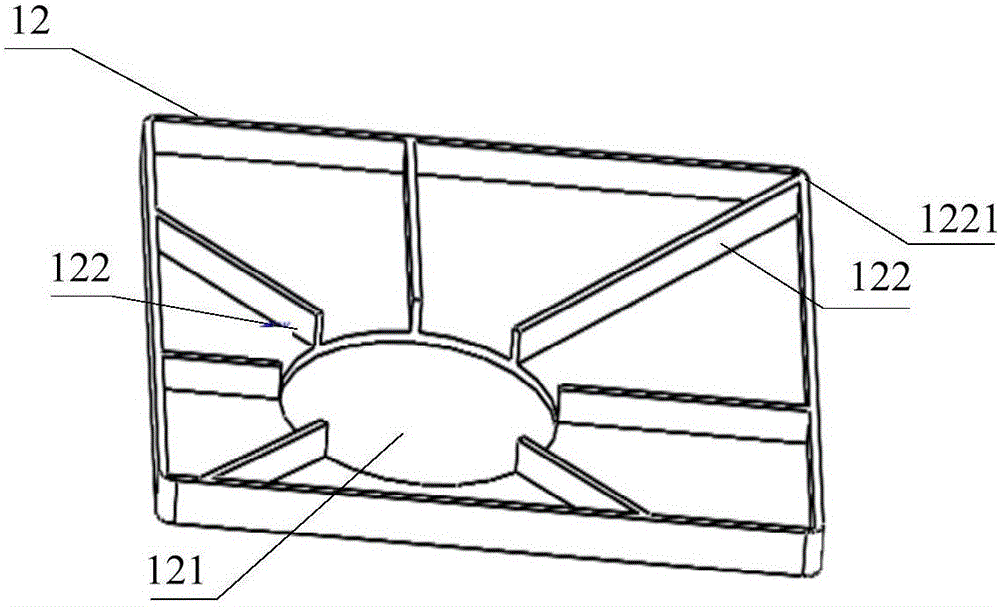

[0036] Such as figure 1 Shown: an air filter 1, including a cover 11, a baffle 12 and a box body 13 that cover each other; a filter screen 2 is arranged between the cover 11 and the baffle 12; a fan 3 is arranged in the box body 13 The top wall of the cover 11 is provided with an air inlet 111; the panel of the baffle 12 is provided with a circular ventilation hole 121, and the panel of the baffle 12 is provided with an air guide strip 122; the side wall of the box body 13 is provided with an outlet The air outlet 131 ; the fan 3 drives the air to flow through the air inlet 111 , the filter screen 2 and the air hole 121 in sequence, and then flows out through the air outlet 131 . The cover body 11 , the baffle plate 12 and the box body 13 are detachably closed to facilitate assembly and disassembly, and also facilitate replacement of the filter screen 2 . The air guide bar 122 makes the air filtered by the filter screen 2 enter the fan 3 smoothly.

[0037] The air guide bar ...

Embodiment 2

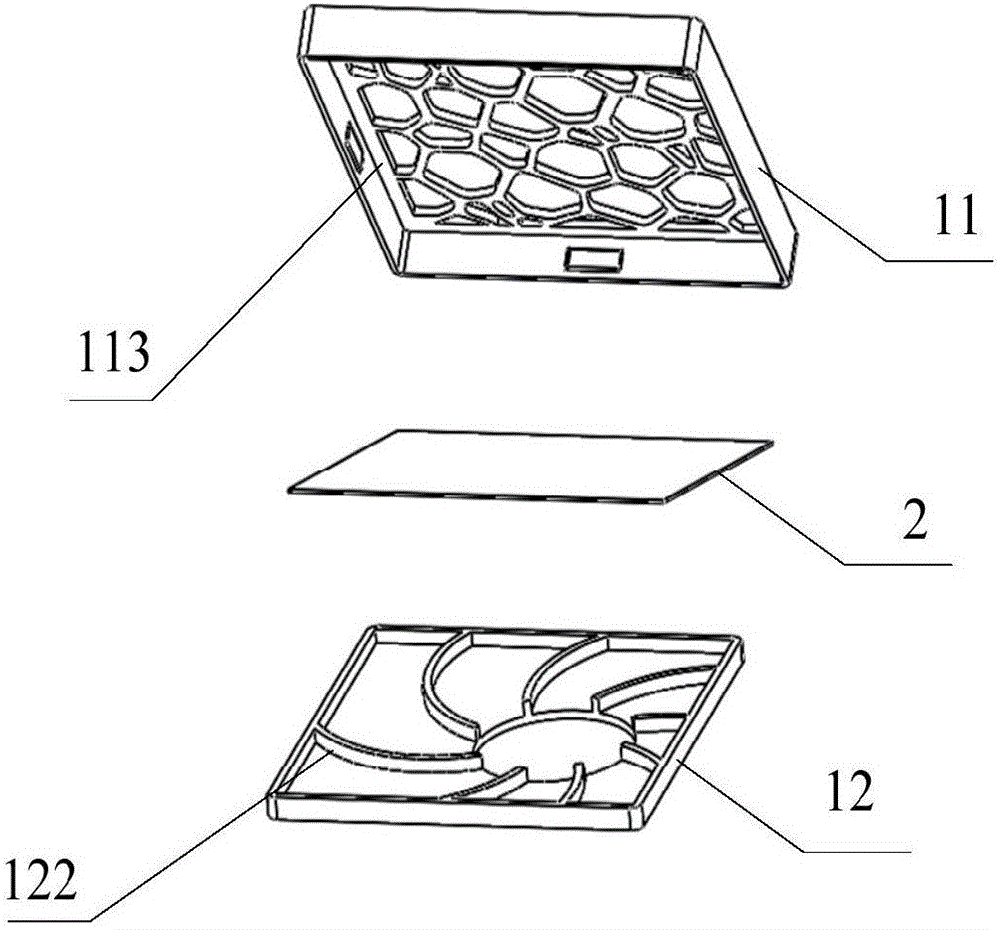

[0039] On the basis of Example 1, such as image 3 As shown in , the air guide bar 122 is arc-shaped, and the clockwise direction of the arc radiation is opposite to the clockwise direction of the fan blade rotation. Through this arrangement, the air guide strip 122 is consistent with the actual direction of the air flow, and the air flow is smoother. When in use, the air guide bar 122 is in contact with the filter screen 2 , which can support and fix the filter screen 2 and prevent the filter screen 2 from hindering the airflow from entering the ventilation hole 121 . The filter screen covers the top wall of the cover. The edge of the baffle 12 is an annular flange 125 . The top wall 113 of the cover body 11 and the air guide bar 122 compress and fix the filter screen 2 , and the top wall 113 of the cover body 11 matches with the annular flange 125 on the edge of the baffle plate 12 and compresses the filter screen 2 . Through fitting and pressing, the baffle plate 12 and ...

Embodiment 3

[0041] Such as Figure 4 As shown: on the basis of Embodiment 1, the filter screen 2 covers the top wall of the cover body 11, and the top wall edge 112 of the cover body 11 matches with the upper edge 132 of the box body 13 and compresses the filter screen 2. Through fitting and pressing, the box body 13 and the filter screen 2 form a sealed cavity, which further improves the sealing performance.

[0042] Protruding blocks 114 are provided on the inner wall of the cover body 11 , and grooves 133 corresponding to and fitting with the positions of the protruding blocks 114 are provided on the outer side of the box body 13 . Through the fit and engagement of the protruding block 114 and the groove 133, it is convenient to disassemble and assemble, and also avoids air leakage, thereby improving the filtering effect. In this embodiment, the protrusions 114 are disposed at relative positions on the inner wall of the cover body 11 , and the grooves 133 are disposed at relative posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com