Supercritical carbon dioxide extraction tank and extraction system including same

A carbon dioxide, extraction tank technology, applied in solvent extraction, gaseous solvent extraction, chemical instruments and methods, etc., can solve the problems of reduced product yield, difficulty in continuous processing of liquid materials, etc., to increase the contact area, avoid downtime, improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

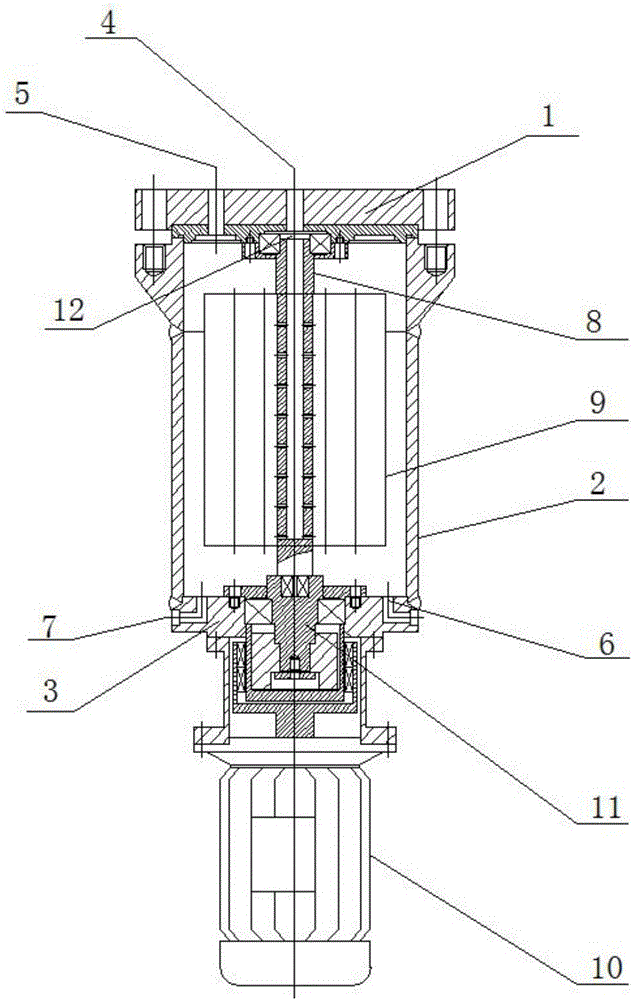

[0027] Such as figure 1 As shown, the present invention provides a supercritical carbon dioxide extraction tank, comprising an extraction tank main body, a refinement part and a power part;

[0028] The main body of the extraction tank includes a top cover 1, a tank side wall 2 and a bottom plate 3 from top to bottom. The tank side wall 2 is a cylinder, and the top and bottom of the cylinder are respectively provided with a first opening and a second opening. Opening; the top cover 1 is detachably covered and arranged at the first opening, the center of the top cover 1 is provided with a material inlet 4, and a solvent outlet 5 is provided beside the material inlet 4; the bottom plate 3 can The dismounting cover is arranged at the second opening, and the bottom plate 3 is provided with a material outlet 6, a solvent inlet 7 and a connecting port, and the connecting port is arranged at the center of the bottom plate 3 for connecting the power The relevant structure of the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com