Fully-digital distributed scintillation crystal lifting furnace control system

A scintillation crystal, all-digital technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of large interference, achieve the effect of convenient centralized monitoring, strong stability, and avoid interruption of the growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

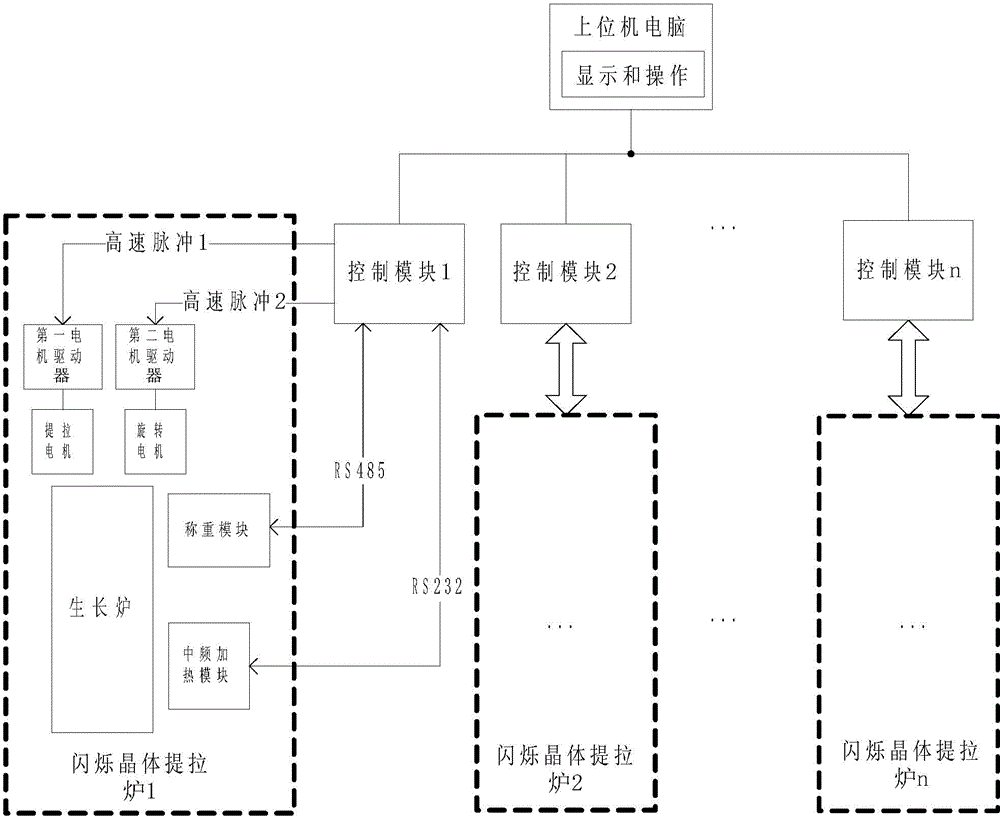

[0035] The invention discloses an all-digital collection and distribution scintillation crystal pulling furnace control system, which has the characteristics of higher degree of automation, more concentrated display operation and management analysis, stronger anti-interference ability and the like. This distributed control system is based on programmable controllers, and has the advantages of decentralized control functions, centralized display and operation, taking into account division and autonomy and comprehensive coordination.

[0036] Such as figure 1 As shown, the fully digitalized collection and distribution scintillation crystal pulling furnace control system disclosed in the present invention includes a host computer, a control module and an execution module, and the control module communicates with the host computer and the execution module respectively. The execution module includes an intermediate frequency heating module to control the temperature of the growth f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com