External optical wave heating type electric water heater provided with water flow sensor with pressure reduction function and non-metallic blow-molded water tank

A technology of water flow sensor and light wave heating, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc. It can solve problems such as water leakage, thermal expansion and cold contraction, cracks in water tanks, pressure explosions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

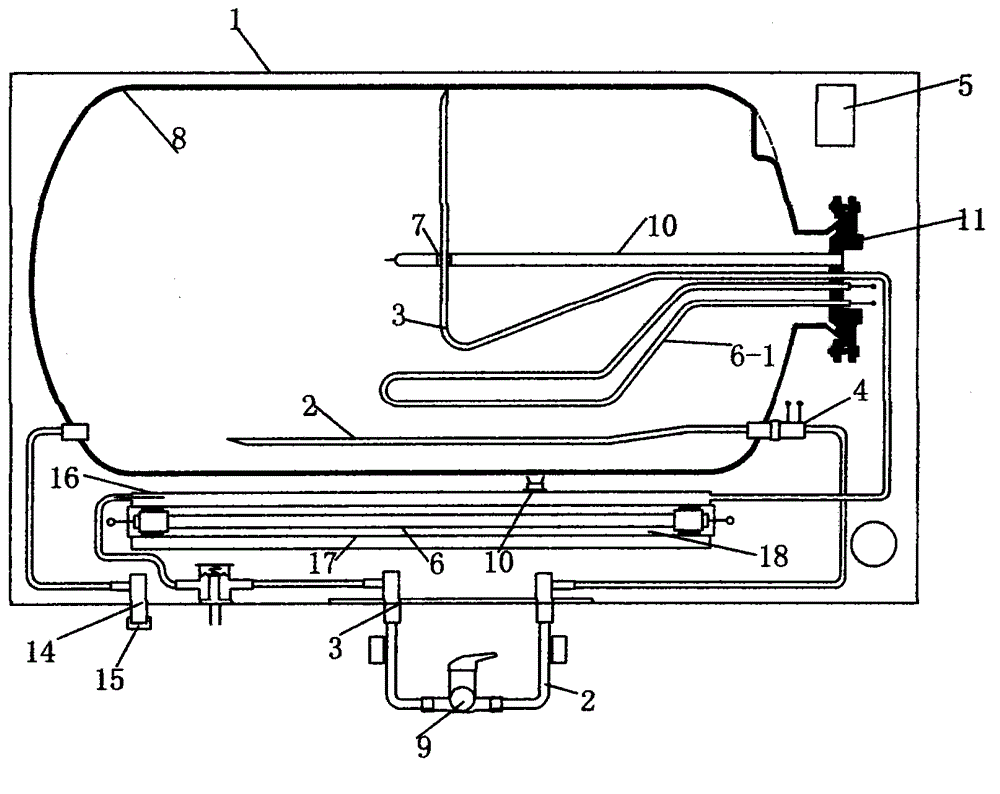

[0015] Attached below Figures 1 to 8 In the accompanying drawings: shell 1, cold water inlet pipe 2, hot water outlet pipe 3, water flow sensor 4 with decompression function, controller 5, halogen tube heated by light wave or carbon fiber tube electric heating tube 6 ( Upper electric heating pipe 6-1, lower electric heating pipe 6-2), sealing and fixing point 7, water tank 8, water nozzle 9, temperature measuring or temperature limiting sensor installation pipe 10, flange 11, pressure relief valve 14, sewage outlet 15 1. Water flows through the water heating device 16, the metal or non-metal casing 17, the air 18, and the water 19.

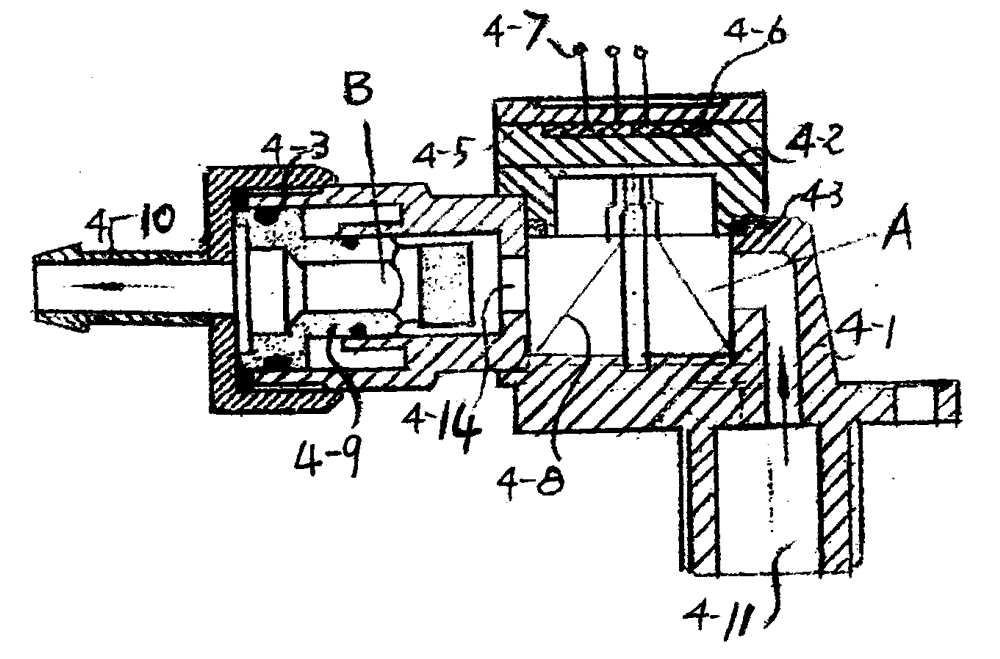

[0016] Figure 1 to Figure 3 It is a water flow sensor 4 with decompression function, which consists of a main body 4-1, a cover plate 4-2, a seal 4-3, a spring 4-4, an installation cover plate 4-5, an induction element 4-6, and a connection terminal 4 -7, impeller or rotor or Hall element 4-8, piston 4-9, interface 4-10, water inlet 4-11. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com