Branch biological oxidation technology for high-arsenic and high-sulfur gold concentrate

A technology of biological oxidation and gold concentrate, applied in the field of biometallurgical materials, can solve the problems of hindering the rapid progress of biological oxidation reaction, high arsenic cannot be removed in time, and low gold leaching rate, so as to shorten the time of biological oxidation, improve the oxidation effect, highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

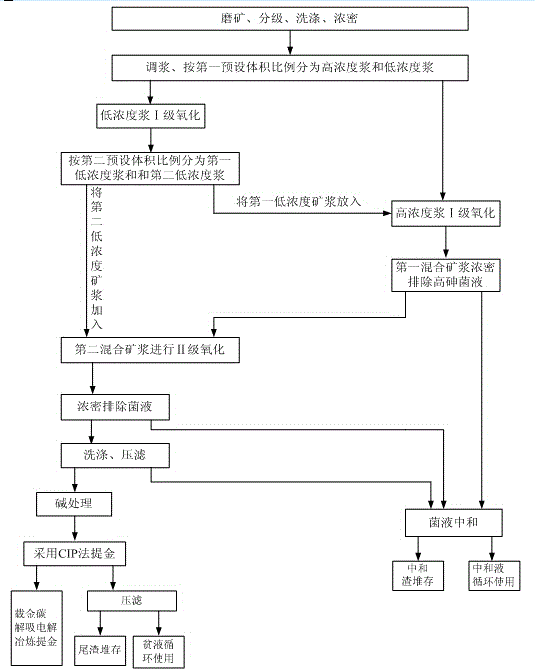

[0026] This embodiment provides a branched biological oxidation process of high-arsenic and high-sulfur gold concentrate, the process includes the following steps:

[0027] (1) Pretreatment: Grinding, grading, washing and thickening the high-arsenic and high-sulfur gold concentrate;

[0028] (2) Pulp separation: Divide the pulp into low-concentration pulp and high-concentration pulp according to the first preset volume ratio;

[0029] Wherein, the first preset volume ratio is 1:4-2:3, the concentration of the low-concentration pulp is 5%-12%, and the concentration of the high-concentration pulp is 15%-25%.

[0030] (3) Level I oxidation: Put the low-concentration pulp and the high-concentration pulp into respective Level I oxidation tanks for Level I oxidation;

[0031] (4) Second-level oxidation: After the first-level oxidation of low-concentration pulp is completed, the second preset volume ratio of low-concentration pulp is placed in the first-level oxidation tank of high-...

Embodiment 2

[0040] This embodiment provides a branch biological oxidation process of high-arsenic and high-sulfur gold concentrate, such as figure 1 As shown, the process includes the following steps:

[0041] (1) Pretreatment: Grinding, grading, washing, and thickening the high-arsenic and high-sulfur gold concentrate; the overflow goes to the reservoir, and the bottom flow of the thickener enters the slurry tank, and then is fed into the ore separator;

[0042] (2) Pulp separation: In the process of ore separation, pulp is adjusted separately, 1 / 3 volume pulp is adjusted to 10% low concentration pulp, and 2 / 3 volume pulp is adjusted to 20% high concentration pulp.

[0043] (3) Level I oxidation: Put the low-concentration pulp and the high-concentration pulp into respective Level I oxidation tanks for Level I oxidation;

[0044] (4) Second-level oxidation: After 2 days of low-concentration pulp I-level oxidation, the low-concentration pulp is divided into the first low-concentration pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com