On-line multi-stage waste heat quenching system

A waste heat quenching and cold water technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve problems such as residual stress hazards, corrosion resistance reduction, and cracking at the core of extruded materials, and achieve shape and dimensional stability, Improve the effect of waste heat quenching and avoid the effect of core cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

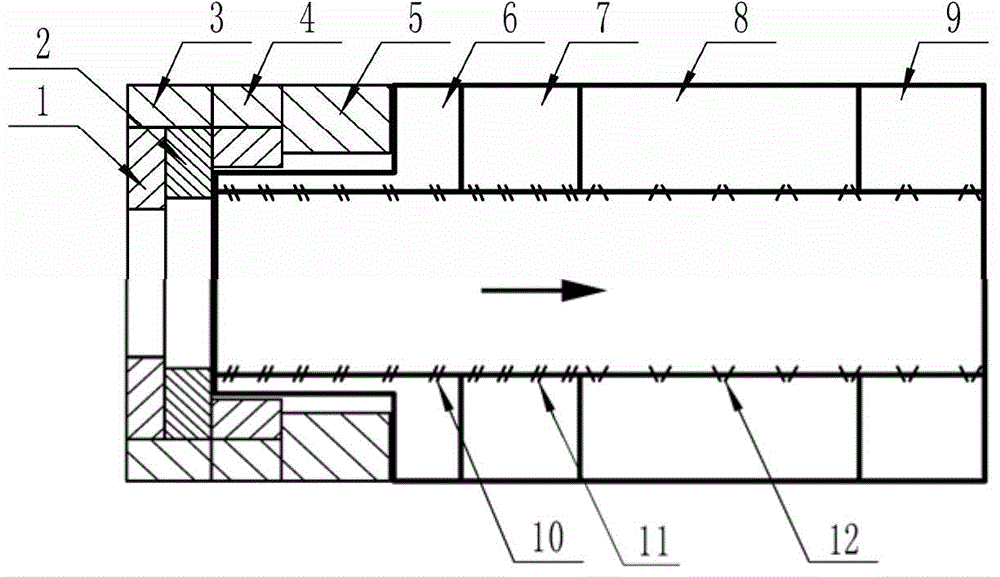

Embodiment 1

[0029] Mg-8wt.%A1-0.4wt.%Zn magnesium alloy (abbreviated as AZ80) is a commonly used commercial magnesium alloy with a thermal conductivity of about 82W / (m K). It is produced by hot extrusion with a thickness of 290mm×230mm. In the process of cross-section extrusion, online quenching is required. The early use of online waste heat quenching guide is simple high-pressure water cooling, the water spray length is 3000mm, and the high-pressure water column is sprayed around the extruded material. The temperature is 400°C, the extrusion speed is 0.8mm / s, and the temperature of the extruded material is at room temperature after cooling through the quenching guide, but it is found that there is a crack in the center of the entire row material during subsequent sawing to length.

[0030] In the follow-up experiment, the quenching method was changed. After the extruded material was extruded from the die, the temperature entering the quenching system was still 400°C, and the speed was st...

Embodiment 2

[0034] Mg-5wt.%Zn-1wt.%Mn magnesium alloy (abbreviated as ZM51) is a deformable magnesium alloy with high thermal conductivity, and its thermal conductivity is about 120W / (m·K). In the process of producing ZM51 magnesium alloy square bar with a size of 290mm×230mm thick and large cross-section by extrusion method, a single water-cooled residual heat quenching guide is used for early cooling, the length of the water spray section is 5 meters, and the inner hole of the guide is circular, realizing 360° Spraying, the temperature before cooling is 380°C, the extrusion speed is 1.2mm / s, and the water temperature is room temperature after cooling. After later performance testing, it was found that the tensile strength of the surface of the ZM51 magnesium alloy extrusion material reached more than 350MPa, while the tensile strength of the core of the extrusion material was only 260MPa. performance gap is large.

[0035] Under the same extrusion temperature and post-extrusion speed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com