Nitrifying bacterium enrichment culture device and culture method

A technology of enrichment culture and culture device, which is applied in the field of nitrifying bacteria enrichment culture device, can solve the problems of long cycle time and long water inflow time, and achieve the effects of preventing loss, ensuring clarity and shortening the culture cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

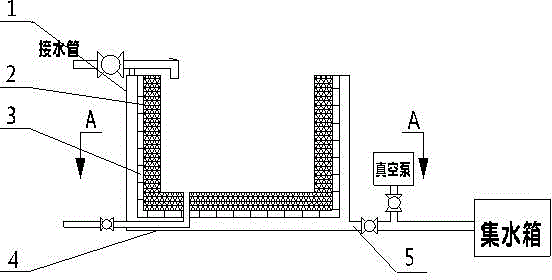

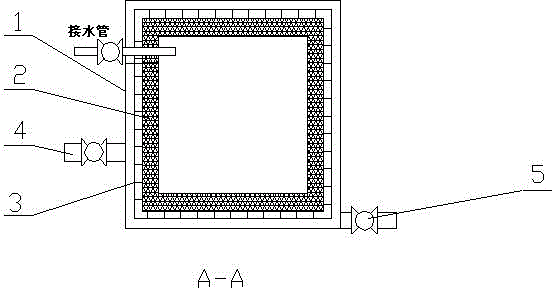

[0041] use figure 1 The culture device shown enriches and cultivates nitrifying bacteria, wherein the thickness of the ceramic membrane plate is 2 cm, and the diameter of the membrane hole is 0.1 μm. According to the initial sludge concentration of 200mg / L, nitrifying bacteria activated sludge was added to the ceramic membrane inner cylinder, and 500mL of culture solution with an ammonia nitrogen concentration of 50mg / L was added at the same time, and the aeration system was started for aeration. During the cultivation process, maintain the dissolved oxygen concentration of the culture system at 1.0-1.5 mg / L, the temperature at 32°C, and the pH value at 7.8. Since the nitrification process is an acid production process, when the pH value is lower than the set value during the cultivation process, the lye is replenished to the culture system through the metering pump. The lye is a saturated solution of sodium bicarbonate. When the pH value reaches the set value, stop the proces...

Embodiment 2

[0049] use figure 1 The culture device shown enriches and cultivates nitrifying bacteria, wherein the thickness of the ceramic membrane plate is 3 cm, and the diameter of the membrane hole is 0.25 μm. According to the initial sludge concentration of 300mg / L, nitrifying bacteria activated sludge was added to the ceramic membrane inner cylinder, and at the same time, 500mL of culture solution with an ammonia nitrogen concentration of 100mg / L was added, and the aeration system was started for aeration. During the cultivation process, maintain the dissolved oxygen concentration of the culture system at 1.0-1.5mg / L, the temperature at 35°C, and the pH value at 8.5. Since the nitrification process is an acid production process, when the pH value is lower than the set value during the cultivation process, the lye is replenished to the culture system through the metering pump. The lye is a saturated solution of sodium bicarbonate. When the pH value reaches the set value, stop the proc...

Embodiment 3

[0053] use figure 1 The shown culture device enriches and cultivates nitrifying bacteria, wherein the thickness of the ceramic membrane plate is 5 cm, and the diameter of the membrane hole is 0.5 μm. According to the initial sludge concentration of 500mg / L, nitrifying bacteria activated sludge was added to the ceramic membrane inner cylinder, and at the same time, 500mL of culture solution with an ammonia nitrogen concentration of 150mg / L was added, and the aeration system was started for aeration. During the cultivation process, maintain the dissolved oxygen concentration of the culture system at 1.0-1.5mg / L, the temperature at 30°C, and the pH value at 7.5. Since the nitrification process is an acid production process, when the pH value is lower than the set value during the cultivation process, the lye is replenished to the culture system through the metering pump. The lye is a saturated solution of sodium bicarbonate. When the pH value reaches the set value, stop the proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com