Nano core-shell structure organic-inorganic compound concrete protective agent and preparation method and application thereof

A nano-core-shell and concrete technology, which is applied in the field of building materials, can solve the problems of long time required, slow process, poor wear resistance and durability, etc., and achieve the effect of increasing service life, good effect, and improving easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

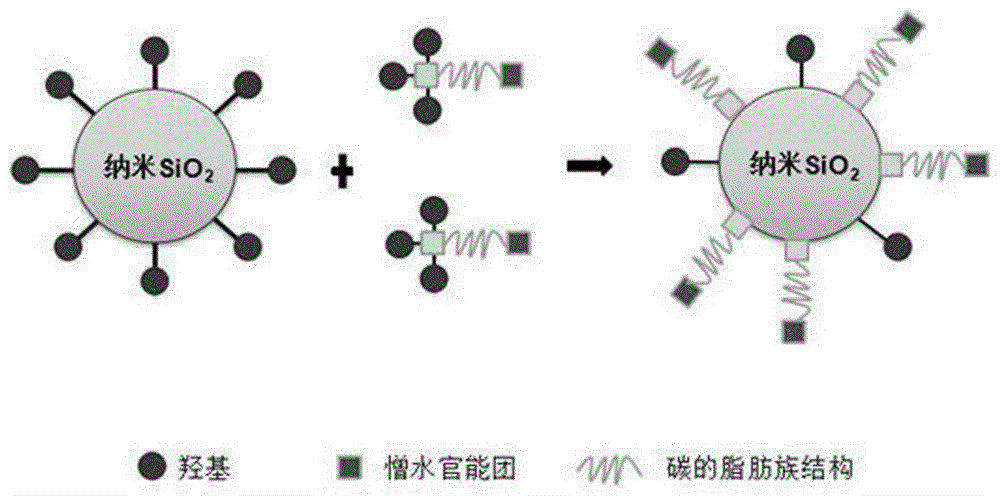

Method used

Image

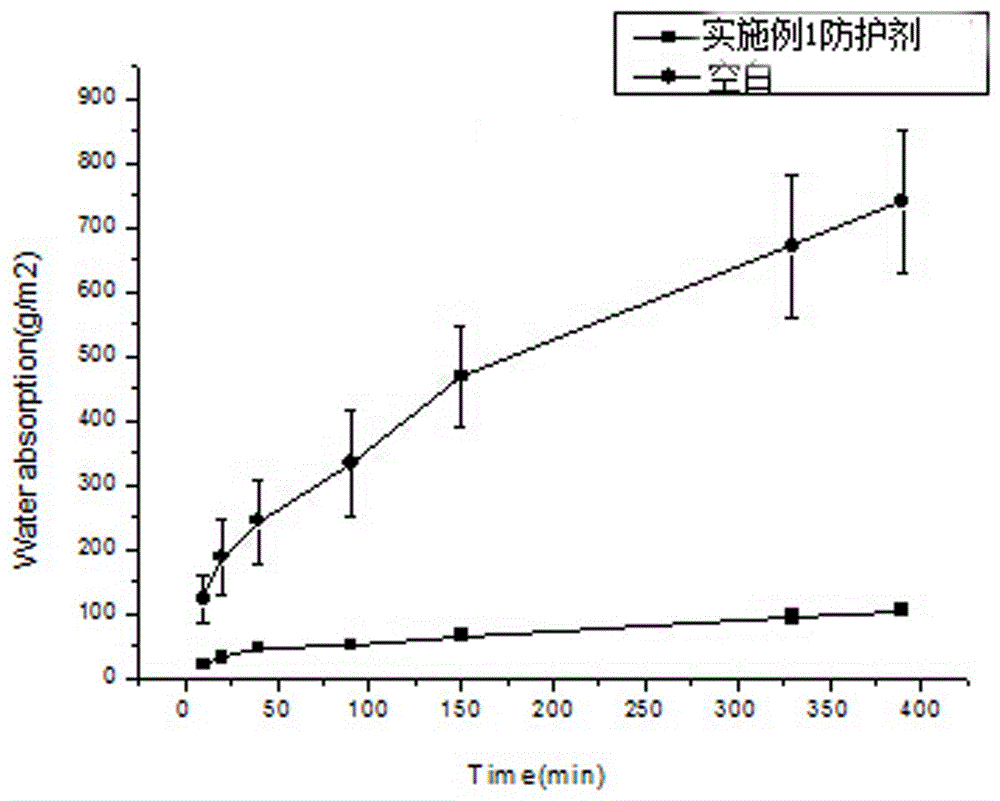

Examples

Embodiment 1

[0048] An organic-inorganic composite concrete protective agent with a nano core-shell structure, the mass percentage of its raw materials is composed of:

[0049] Polymethylhydrogensiloxane 0.5%;

[0050] Ethyl orthosilicate 6%;

[0051] Tetrahydrofuran 92.9%;

[0052] Ethylenediamine 0.1%;

[0053] Deionized water 0.5%.

[0054] The preparation method is: weigh tetrahydrofuran according to the proportion, add ethylenediamine to adjust the pH to 8-12, then add polymethylhydrogensiloxane, stir with a magnetic stirrer for 30 minutes, then add ethyl orthosilicate, continue stirring for 11 hours, and finally add Stir with deionized water for 3 hours until the solution turns from transparent to turbid, and the reaction is complete. Use a high-speed centrifuge at a speed of 10,000 rpm for 5 minutes, filter the supernatant, and collect the solid at the bottom of the centrifuge tube, which is the nano-core-shell organic- Inorganic composite concrete protective agent.

Embodiment 2

[0056] An organic-inorganic composite concrete protective agent with a nano core-shell structure, the mass percentage of its raw materials is composed of:

[0057] Vinyltriethoxysilane 1.4%;

[0058] Ethyl orthosilicate 8%;

[0059] Ethanol 89%;

[0060] Ethylenediamine 0.1%;

[0061] Deionized water 1.5%.

[0062] The preparation method is: weigh ethanol according to the proportion, add ethylenediamine to adjust the pH to 8-11, then add polymethyl hydrogen siloxane, stir with a magnetic stirrer for 30 minutes, then add ethyl orthosilicate, continue stirring for 10 hours, and finally add Stir with deionized water for 2 hours until the solution turns from transparent to turbid, and the reaction is complete. Use a high-speed centrifuge at a speed of 10,000 rpm for 5 minutes, filter the supernatant, and collect the solid at the bottom of the centrifuge tube, which is the nano-core-shell structure organic- Inorganic composite concrete protective agent.

Embodiment 3

[0064] An organic-inorganic composite concrete protective agent with a nano core-shell structure, the mass percentage of its raw materials is composed of:

[0065] Isobutyltriethoxysilane 0.9%;

[0066] Ethyl orthosilicate 6%;

[0067] Methanol 92%;

[0068] Ammonia 0.1%;

[0069] Deionized water 1%.

[0070] The preparation method is: weigh methanol according to the proportion, add ammonia water to adjust the pH to 8-11, then add isobutyltriethoxysilane, stir with a magnetic stirrer for 30 minutes, then add ethyl orthosilicate, continue stirring for 12 hours, and finally add Stir the ionized water for 3.5h until the solution turns from transparent to turbid, and the reaction is completed. Use a high-speed centrifuge, 10000rp m Centrifuge at a speed of 5 min, filter the supernatant, and collect the solid at the bottom of the centrifuge tube, which is the nano-core-shell structure organic-inorganic composite concrete protective agent of this embodiment.

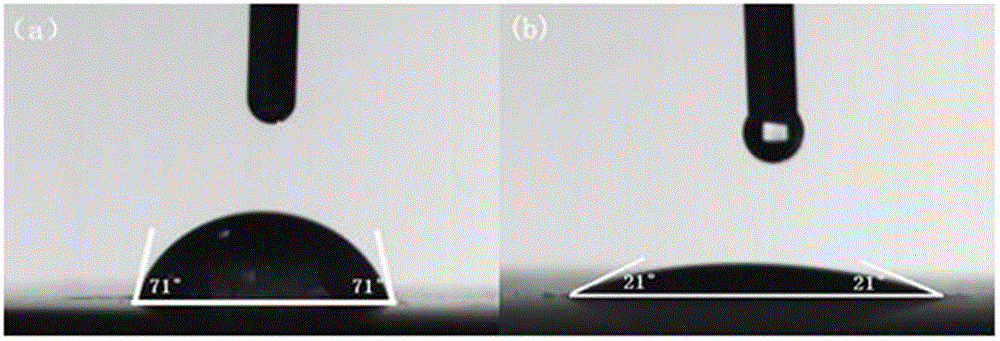

[0071] Applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com