Automatic feeding device for punching machine

A technology of automatic feeding and punching machine, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of laborious, time-consuming and low efficiency of manual feeding, and achieve the effect of improving accuracy and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

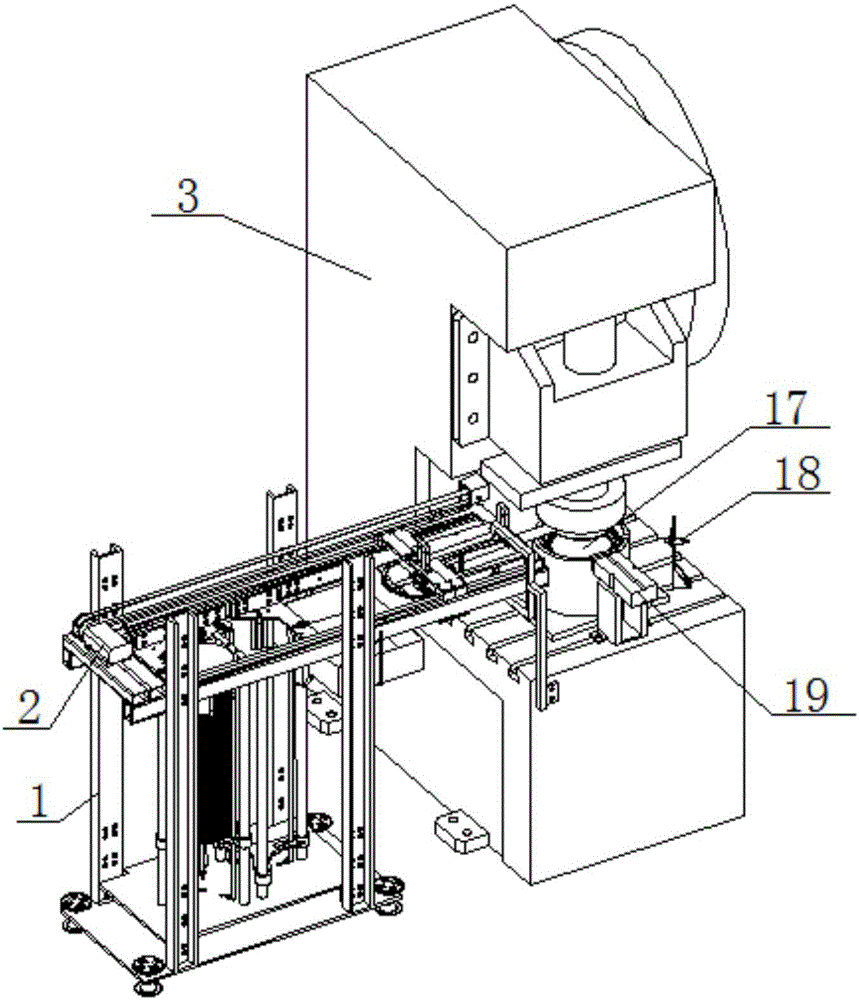

[0030] as attached Figure 1-5 As shown, the blank 20 mentioned in the present invention refers to a circular metal sheet with two plane faces.

[0031] An automatic feeding device for a stamping machine, comprising a frame 1, a feeding mechanism, a retrieving mechanism, a detection disc 15, a blank detection and positioning mechanism, and a punching machine 3, the feeding mechanism, the retrieving mechanism, and the detection disc 15 are all installed on the frame 1 Above, the detection disc 15 is located at the midpoint between the feeding position of the feeding mechanism and the punching position of the punching machine 3, the blank detection and positioning mechanism is installed on the punching machine 3, the frame 1 is connected to the punching machine 3, and the blank passes through the feeding mechanism Send it to the pick-up position, and then the pick-up mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com