High-temperature-resistant aramid filter cloth capable of facilitating dust removing and preparation method thereof

A high-temperature-resistant and dust-cleaning technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as the drop in the output of the asphalt mixing plant, the unfavorable dust removal by the dust collector, and the rough surface of the needle-punched felt. Small dust holding capacity, increasing dust stripping rate and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

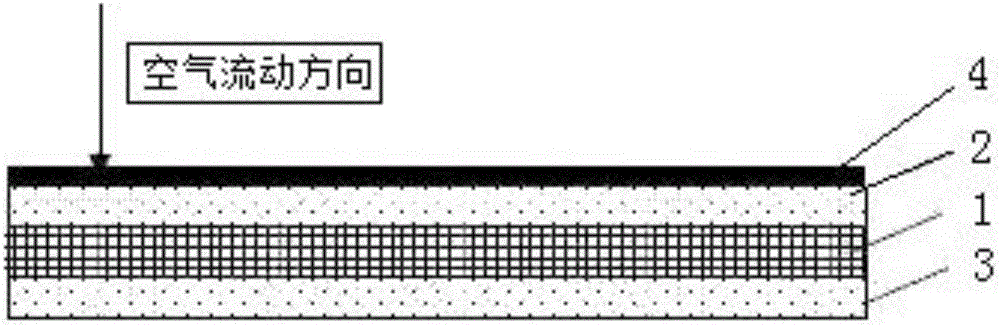

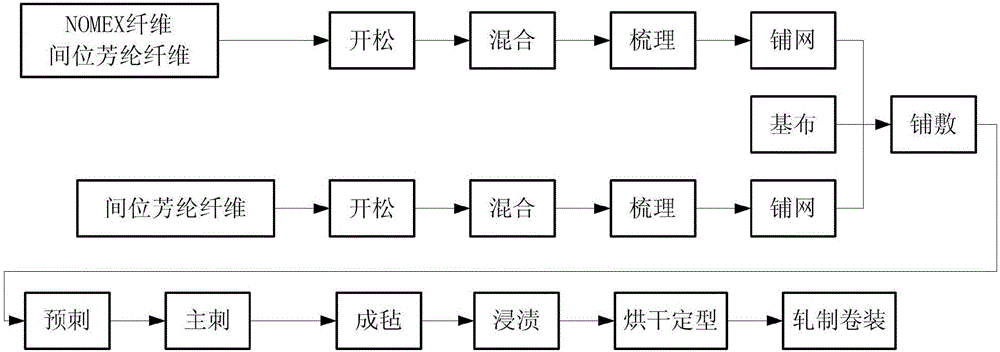

[0024] A kind of aramid high-temperature-resistant filter cloth with easy-cleaning function of this embodiment includes a base cloth layer 1 made of 100% PTFE reinforced base cloth in the middle, and the upper surface of the base cloth layer 1 is provided with microfiber Dust surface layer 2, the lower surface of the base fabric layer 1 is provided with a breathable air purification surface layer 3, the superfine fiber dust facing surface layer 2 is composed of NOMEX fiber and meta-aramid fiber netting, and the breathable air purification surface layer 3 is composed of 2D The base fabric layer 1, the superfine fiber dust surface layer 2 and the air-permeable air purification surface layer 3 are needle-punched into a felt, and the surface of the felt has a PTFE emulsion impregnated layer 4, and the impregnated layer contains talcum powder group point.

[0025] Among them, the two components of the microfiber dust-resisting surface layer are composed of dog-bone ultrafine denier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com