Automatic sample digestion and preparation instrument

A sample and automatic technology, applied in the field of chemical experiment instruments, can solve the problems of acid mist escaping pollution, slow digestion speed, low energy utilization efficiency, etc., and achieve the effect of energy saving and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Automatic sample digestion and preparation instrument

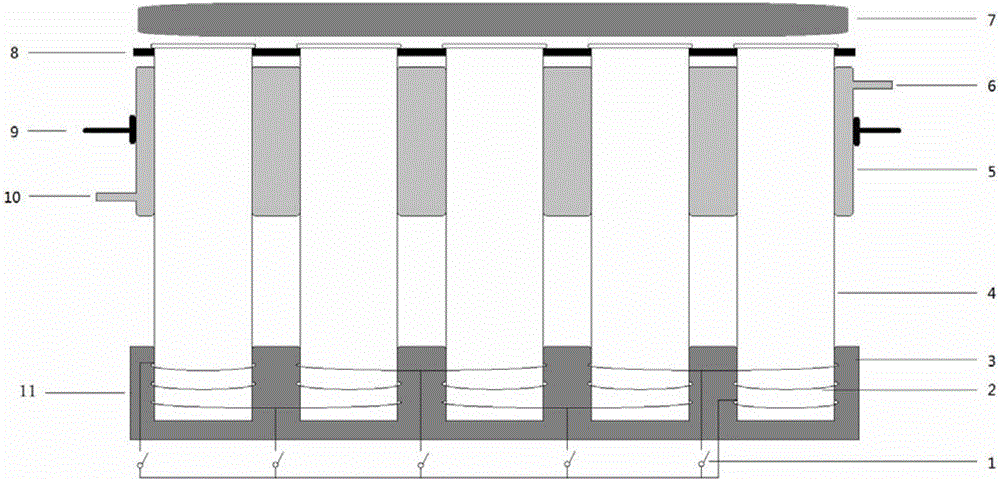

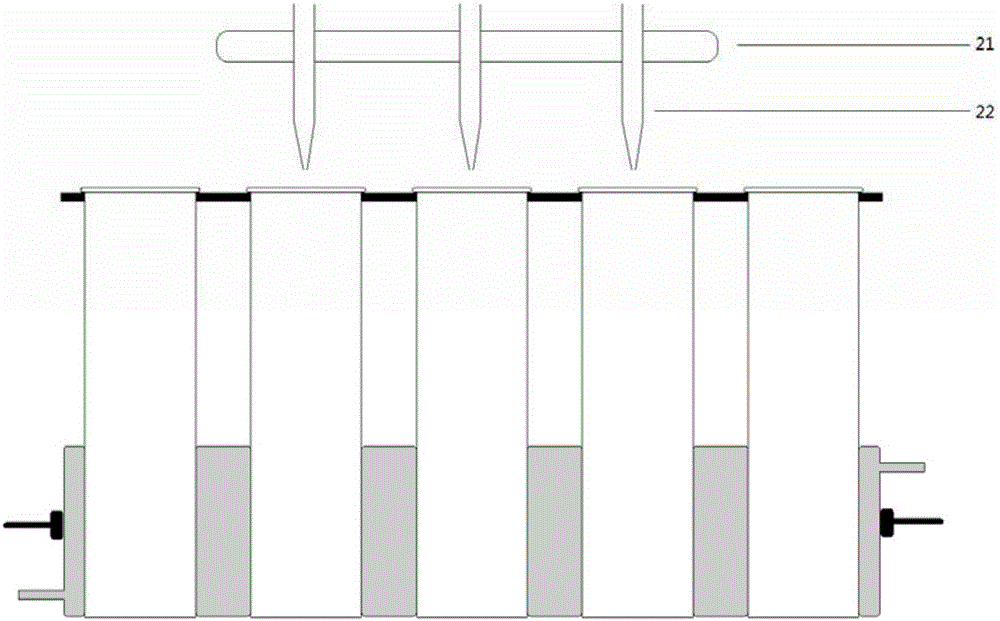

[0028] Such as figure 1 As shown, the automatic sample digestion and preparation instrument includes an electric heating furnace 11, a reaction tube 4, a water bath jacket 5, a bracket 8, an acid mist filter 7, a lifting device, a horizontal reciprocating motion transmission mechanism, a sample inlet 22, a peristaltic pump and Movement control device 21.

[0029] The sample inlet 22, the bracket 8, the water bath jacket 5, and the electric furnace 11 are sequentially arranged from top to bottom.

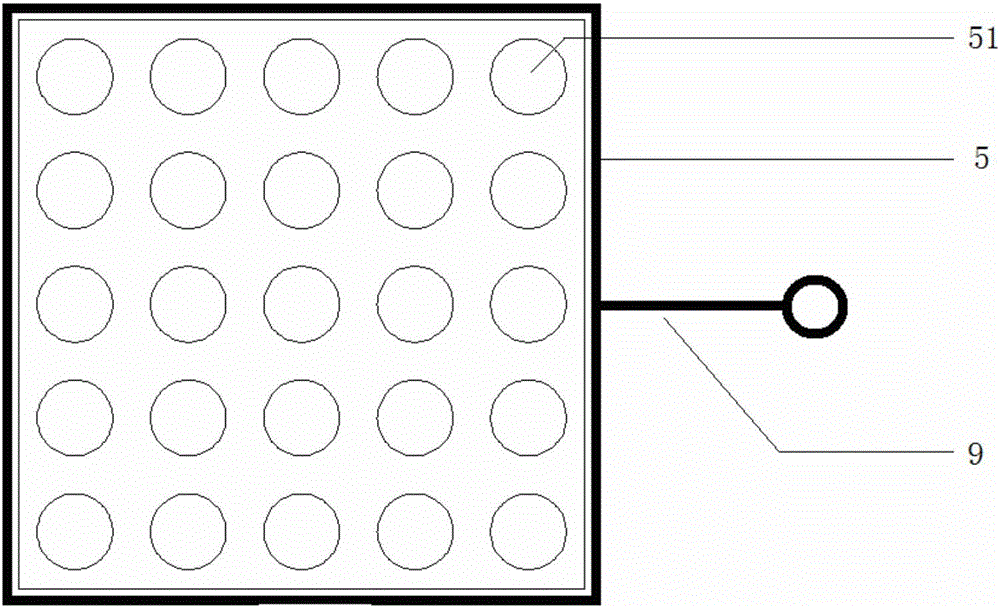

[0030] Such as figure 1 with 3 As shown, the water bath jacket 5 is a container with a water inlet 10 and a water outlet 6, and the container has a plurality of through holes 51 for containing the reaction tube 4. The material of the water bath jacket 5 is a plastic with a thermal conductivity exceeding 0.4w / mK. The water bath jacket 5 is connected with a horizontal reciprocating transmission mechanism through a ...

Embodiment 2

[0034] Example 2 Molybdenum blue colorimetric method for determination of total phosphorus content in soil

[0035] The soil samples are digested with concentrated sulfuric acid and perchloric acid under heating conditions. After the digestion is completed, they are diluted, sodium hydroxide solution is added to adjust the pH value, and then the volume is fixed for the subsequent color reaction, and the color is compared with a spectrophotometer.

[0036] The operation steps of using the automatic sample digestion and preparation instrument are as follows:

[0037] About 0.1 g of soil sample is added to each reaction tube 4. Before the digestion, the reaction tube bracket 8 is in an elevated state, and 3 ml of concentrated sulfuric acid and 0.3 ml of perchloric acid are automatically added to each reaction tube through the injection port 22. Subsequently, the reaction tube bracket 8 is lowered, the lower part of the reaction tube is put into the cavity of the electric furnace, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com