Safety valve with buffer performance

A safety valve and performance technology, applied in the field of safety valves, can solve the problems of high machining accuracy of parts, unfavorable for stable mass production, lack of buffer performance, etc., to meet the requirements of mass production, simple and compact connection and processing, handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

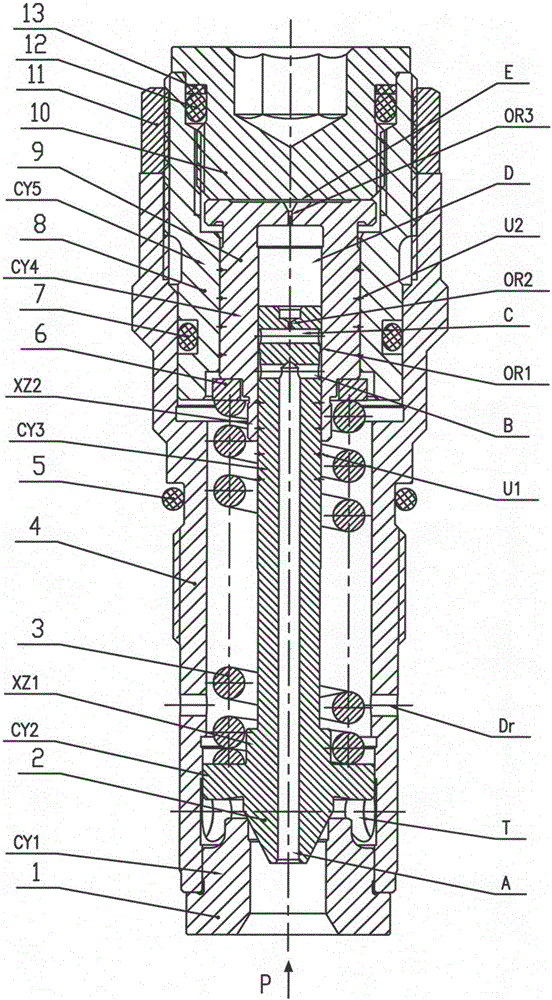

[0018] The present invention is a safety valve with cushioning performance, such as figure 1 Shown is a structural schematic diagram of a safety valve with buffer performance. The inside of the front end of the valve sleeve 4 is connected with the first cylinder CY1 on the valve seat 1 through interference fit, so as to be fixed on the lower end surface of the valve sleeve, and the upper end surface of the valve seat 1 cooperates with the tapered surface of the valve core 2 to form a line seal. There is an annular groove in the middle outer circle of the valve sleeve 4, and the first O-shaped sealing ring 5 is connected in the groove. The external thread of the middle section and the internal thread of the upper end are respectively arranged on the valve sleeve 4, and the internal thread of the upper end is connected with the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com