Automatic grouting hoop floating shoes

A technology of automatic grouting and floating hoop, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc. The size cannot be deformed, and the automatic current limiting cannot be realized, so as to avoid tube accidents, good sealing and good drillability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

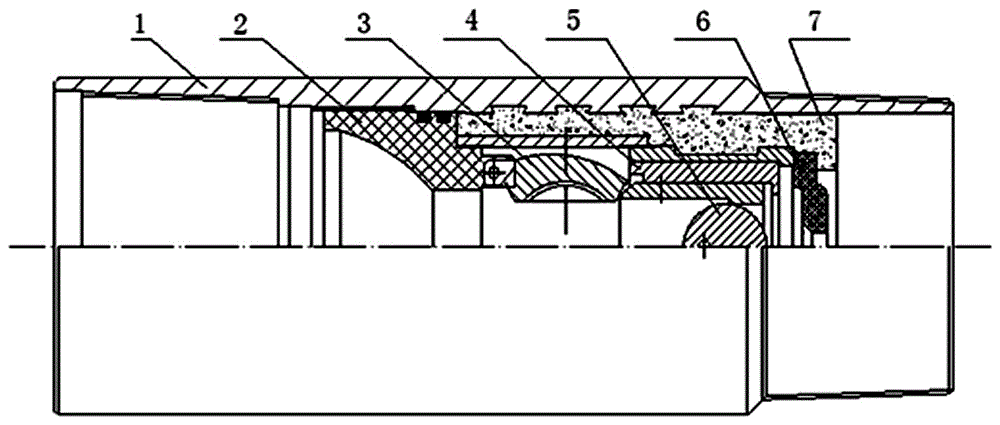

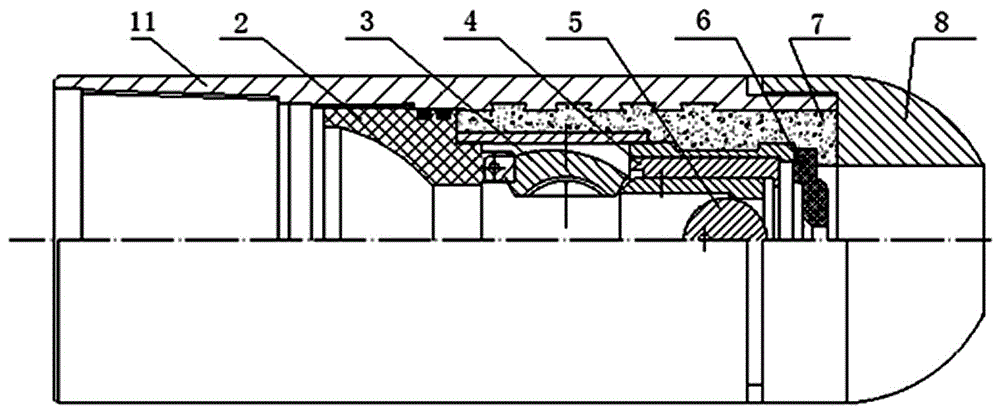

[0026] Below in conjunction with accompanying drawing, floating hoop and floating shoes of the present invention are described in detail.

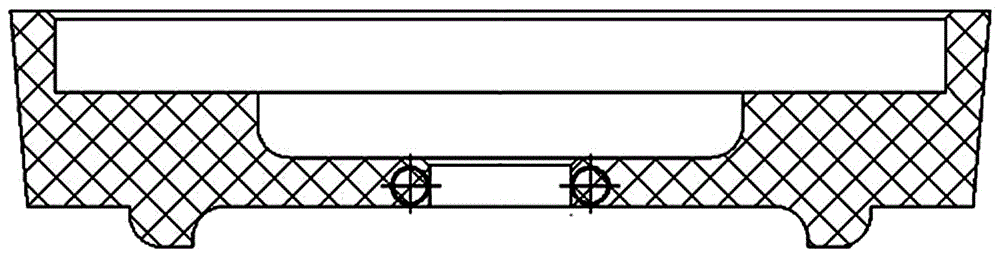

[0027] Such as figure 1 and figure 2 As shown, the floating hoop of the present invention includes a floating hoop body 1, a shut-off valve seat 2, a shut-off valve 3, a shear mechanism 4, an alloy ball 5 and a flow control valve 6, and the floating shoe of the present invention includes a floating shoe body 11, a shut-off valve seat 2 , cut-off valve 3, shearing mechanism 4, alloy ball 5, flow control valve 6 and guide cap 8, the present invention is processed with the casing circle that is connected with oil casing pipe on the upper and lower ends of the floating hoop body 1 and the upper end of the floating shoe body 11 The thread or casing partial trapezoidal thread, the lower end of the floating shoe body 11 is equipped with a guide cap 8, the inner wall of the floating hoop body 1 and the floating shoe body 11 is connected with a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com