Reactive dye printing paste as well as preparation method and application thereof

A technology of reactive dyes and printing pastes, applied in the field of textile and printing and dyeing, can solve the problems of low cost, low grade, high printing cost, etc., and achieve the effect of low cost, good stability and good colloidal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

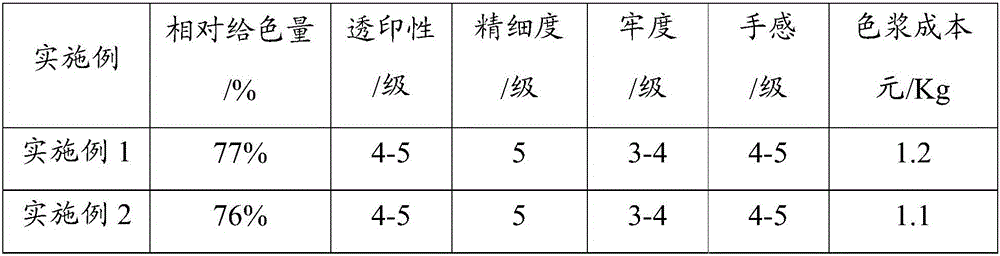

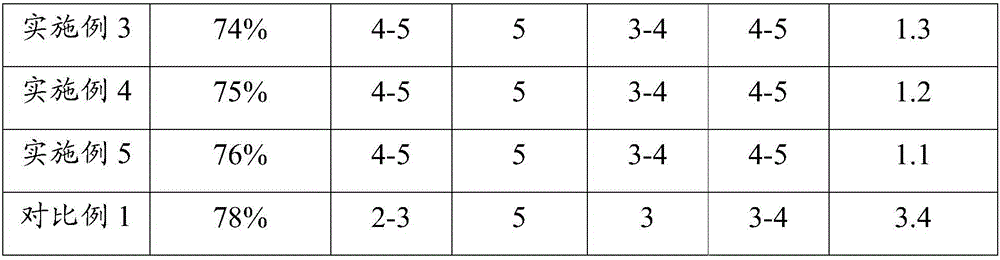

Examples

Embodiment 1

[0040] (1) Fabric: 21 S Pure cotton towel (weight: 300g / cm 2 )

[0041] (2) The process flow is as follows:

[0042]Compound paste (reactive dye printing paste, the same below) preparation: add 3Kg kerosene (boiling range 170-325°C) to the reaction kettle, slowly heat up to 40°C, and keep stirring (speed: 200-800rpm) Slowly add 0.4Kg of composite emulsifier composed of Span 80, Tween 80, and sodium petroleum sulfonate. After the system is completely transparent, add 10Kg of sepiolite, 4Kg of urea, 1Kg of anti-staining salt S, 1Kg of soda ash, and mix After uniformity, add water to make the total amount 50Kg, continue to stir until a uniform viscous paste is formed, then slowly lower the temperature to room temperature, and filter to obtain a composite paste.

[0043] Preparation of color paste: Add 4Kg of the prepared compound paste into the chemical tank, melt 0.2Kg of Active Yanlan KNR with 1Kg of hot water, dissolve it completely, filter it into the compound paste, add w...

Embodiment 2

[0051] (1) Fabric: 21 S Pure cotton towel (weight: 300g / cm 2 )

[0052] (2) The process flow is as follows:

[0053] Preparation of compound paste: Add 6Kg kerosene (boiling range 170-325°C) into the reaction kettle, slowly raise the temperature to 50°C, and slowly add Sipan 80, polyoxyethyl ether oil under continuous stirring (speed: 200-800rpm) Ester and sodium petroleum sulfonate form a composite emulsifier of 0.8Kg. After the system is completely transparent, add 5Kg of sepiolite, 6Kg of urea, 2Kg of anti-staining salt S, and 2Kg of soda ash under stirring. After mixing evenly, add water to make the total amount It is 50Kg, continuously stirs to uniform thick paste, then temperature is slowly lowered to room temperature, after filtering, obtains composite paste.

[0054] Preparation of color paste: Add 6Kg of the prepared compound paste to the chemical tank, melt 1Kg of active red M8B with 1Kg of hot water, dissolve it completely, filter it into the compound paste, add ...

Embodiment 3

[0062] (1) Fabric: 21 S Pure cotton tencel blended towel (weight: 320g / cm 2 )

[0063] (2) The process flow is as follows:

[0064] Preparation of compound paste: add 5Kg kerosene (boiling range 170-325°C) into the reaction kettle, slowly heat up to 60°C, and slowly add Tween 80, sodium petroleum sulfonate under continuous stirring (speed: 200-800rpm) , Polyoxyethyl ether oleic acid ester constitutes 0.7Kg of composite emulsifier. After the system is completely transparent, add 8Kg of sepiolite, 5Kg of urea, 1Kg of anti-staining salt S, 1Kg of soda ash under stirring, and after mixing evenly, add water to make the total amount It is 50Kg, continuously stirs to uniform thick paste, then temperature is slowly lowered to room temperature, after filtering, obtains composite paste.

[0065] Preparation of color paste: Add 5Kg of the prepared compound paste into the chemical tank, melt 0.6Kg of active yellow KRN with 1Kg of hot water, dissolve it completely, filter it into the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com