Distributed energy system based on blast furnace ironmaking

A distributed energy, blast furnace ironmaking technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve problems affecting the development and progress of the iron and steel industry, energy waste and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

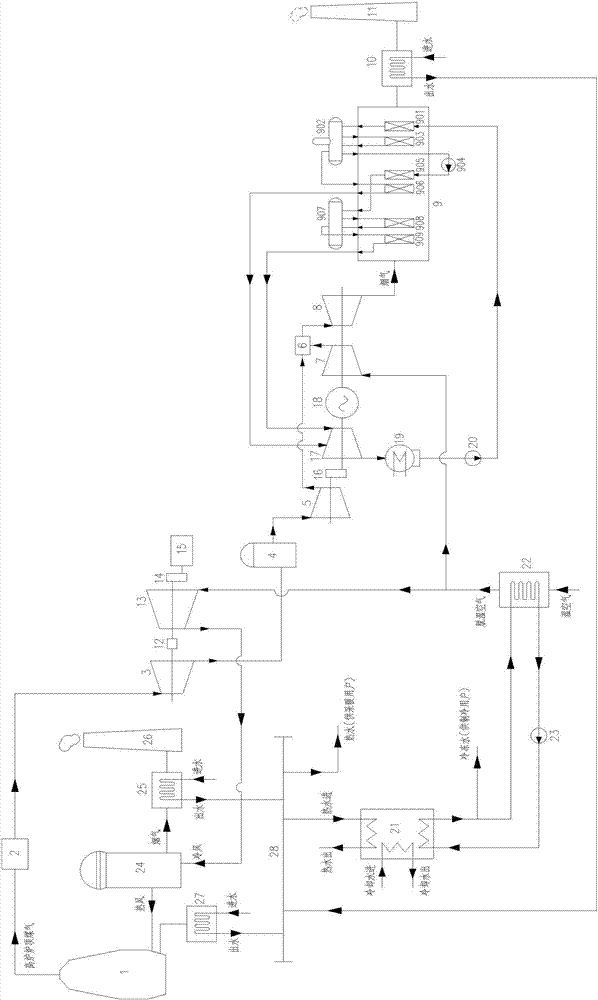

[0028] Such as figure 1 As shown, the distributed energy system based on blast furnace ironmaking in this embodiment includes blast furnace 1, gas purification device 2, gas turbine 3, gas cabinet 4, gas compressor 5, combustion chamber 6, air compressor 7, gas turbine 8, Waste heat boiler 9, first flue gas-water heat exchanger 10, first chimney 11, transmission clutch 12, blast furnace blower 13, first gear box 14, electric motor 15, second gear box 16, steam turbine 17, generator 18 , condenser 19, condensate pump 20, hot water absorption refrigeration unit 21, air dehumidification device 22, circulating water pump 23, hot blast stove 24, second flue gas-water heat exchanger 25, second chimney 26, blast furnace Slag waste heat recovery device 27, hot water main pipe 28. in:

[0029] The blast furnace 1 is connected to the gas purification device 2, the gas turbine 3, the gas cabinet 4, and the gas compressor 5 sequentially through the gas pipeline. The gas purification dev...

Embodiment 2

[0047] The distributed energy system based on blast furnace ironmaking in this embodiment provides a specific waste heat boiler structure on the basis of Embodiment 1.

[0048] The waste heat boiler 9 includes a low-pressure section economizer 901, a low-pressure section drum 902, a low-pressure section evaporator 903, a feed water pump 904, a high-pressure section economizer 905, a low-pressure section superheater 906, a high-pressure section drum 907, a high-pressure High-pressure section evaporator 908, high-pressure section superheater 909 and corresponding connecting pipes, wherein, the high-pressure section superheater 909, high-pressure section evaporator 908, low-pressure section superheater 906, high-pressure section economizer 905, and low-pressure section evaporator 903 , and low-pressure section economizer 901 are arranged in sequence along the flue gas flow in the waste heat boiler. Between the low-pressure section drum 902 and the low-pressure section evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com