Utilization method of waste liquid produced by coal chemical ash removal and coal ash removal method

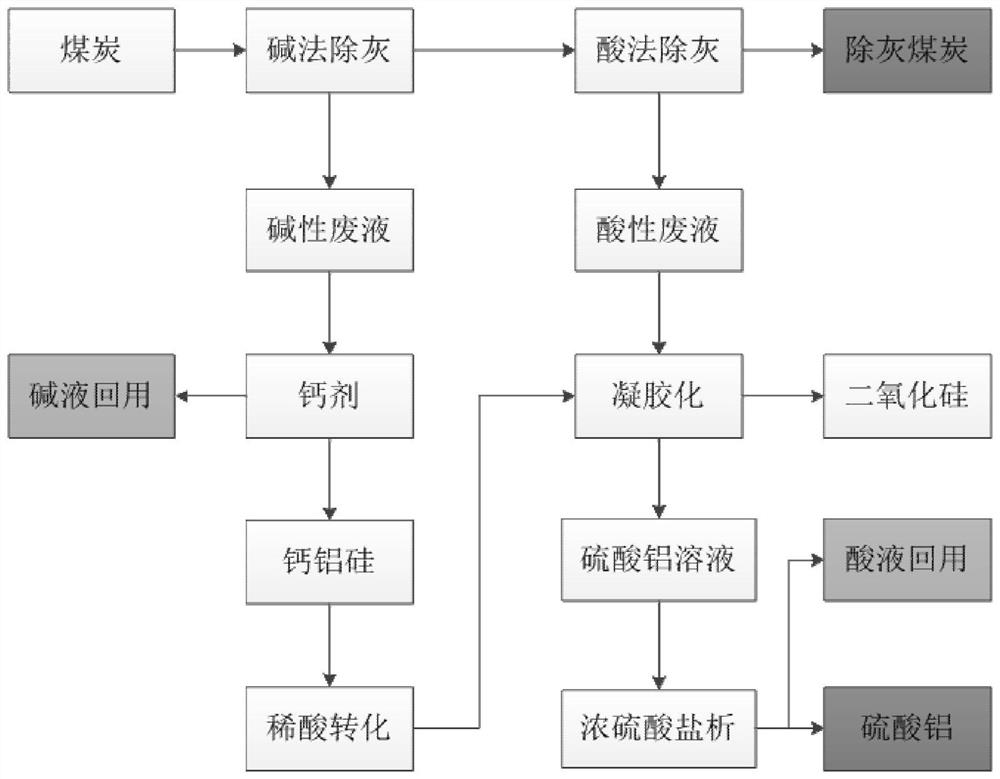

A technology of coal chemistry and waste liquid, applied in chemical instruments and methods, aluminum-sulfur compounds, multi-stage treatment of water/sewage, etc., can solve the problem that waste liquid cannot be effectively and fully utilized, and achieve the effect of optimizing integration and simplifying extraction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Production of waste liquid

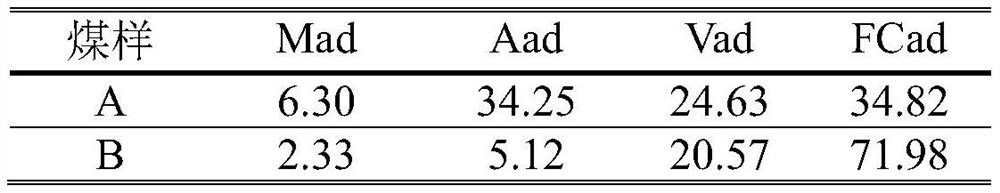

[0051] Coal sample A 400 g, 700 g of potassium hydroxide and 400 ml (liquid solid weight ratio 11: 4), mixed at 120 ° C for 9 hours. Add 1L water dilution cooling, washed 1 hour, washed, resulting in a base after the alkaline method and the alkaline waste liquid. 10 wt% dilute hydrochloric acid was added to the coal after the acid ratio of 1.5: 1 was added to the ground after the gray, and 30 minutes were immersed at 60 ° C for 30 minutes, and the dried coal and acid waste liquid were obtained.

[0052] (2) Use of waste liquid

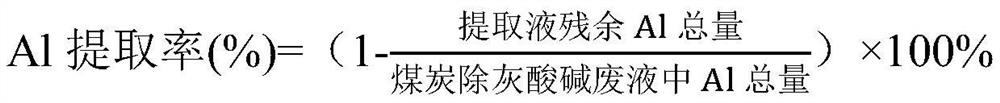

[0053] To the resulting alkaline waste liquid (amount of 50 g / l, 1L alkaline waste liquid added to 50 g of calcium hydroxide) was carried out at 75 ° C for 1 hour, and the first filter residue was filtered. (Aluminum calcium silicon mixture) and the first filtrate, in the first filter residue (aluminum calcium silicon mixture), the aluminum oxide gauge Al content is 29% by weight, with a calcium oxide gauge Ca cont...

Embodiment 2

[0059] (1) Production of waste liquid

[0060] Referring to CN1708574A, the coal sample B is 100 g, and 50 g of sodium hydroxide and 320 ml (liquid solid mass ratio 4: 1), mixed at 250 ° C, and stirred in the autoclave for 9 hours. After filtration, the alkaline waste liquid is obtained. 8 wt% dilute sulfuric acid was added to the filter cake in the filter cake, 75 ° C for 30 minutes, and the washing was obtained from the filter cake.

[0061] (2) Use of waste liquid

[0062] To the obtained alkaline waste liquid (an addition amount of 8 g / l, 1L alkaline waste solution was added to the calcium hydroxide), and the first reaction was carried out at 30 ° C for 2 hours, and the first filter residue was filtered. Calcium silicon mixture) and the first filtrate, in the first filter residue (aluminum calcium silicon mixture), with an aluminum oxide gauge Al content to 76 wt%, and the content of the calcium oxide gauge is Si content in the silica. 8WT%, recovery of the first filtrate (m...

Embodiment 3

[0071] According to the method of the method, the resource utilization of the waste liquid produced by coal chemical except ash, and calcium chloride is used for calcium hydroxide when adding calcium hydroxide to the obtained alkaline waste liquid. The remaining conditions are the same as those of Example 1.

[0072] RESULTS: The extraction rate of aluminum oxide gauge Al is 91%, and the main product of the crystallization of salting is aluminum sulfate. However, the first filtrate is a potassium chloride solution, and it is not possible to directly reuse the coal alkali method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com