Additive for preparation of cellulose and preparation method of cellulose

A technology of cellulose and additives, applied in biochemical equipment and methods, using microorganism/enzyme cellulose treatment, fiber raw material treatment, etc., can solve the problems of complex composition, instability, and large difference in fiber length, etc., and achieve simple process , Improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

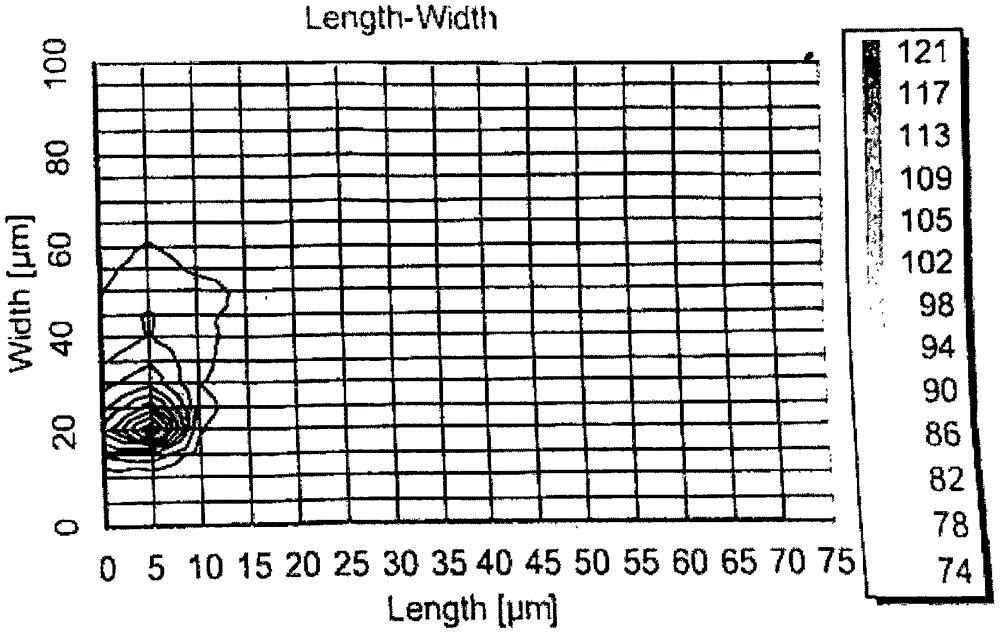

Image

Examples

Embodiment 1

[0038] The present invention is an additive for preparing cellulose, which is composed of the following raw materials: 10kg of brewer's yeast, 10kg of urea, 12kg of fatty alcohol polyoxyethylene ether, 8kg of alkylphenol polyoxyethylene ether, 12kg of lipase, 3kg of cellulase, black Aspergillus 3kg and α-amino acid ester hydrolase and α proteolytic enzyme 3kg.

Embodiment 2

[0040] The present invention is an additive for preparing cellulose, which is composed of the following raw materials: 15kg of brewer's yeast, 18kg of urea, 18kg of fatty alcohol polyoxyethylene ether, 12kg of alkylphenol polyoxyethylene ether, 18kg of lipase, 8kg of cellulase, black Aspergillus 8kg and α proteolytic enzyme 8kg.

Embodiment 3

[0042] The present invention is an additive for preparing cellulose, which consists of the following raw materials: 10-kg brewer's yeast, 18 kg urea, 18 kg fatty alcohol polyoxyethylene ether, 8 kg alkylphenol polyoxyethylene ether, 12 kg lipase, cellulase 8kg, Aspergillus niger 8kg and hydrolase 3kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knocking degree | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com