Treatment method for removing cadmium in electroplating wastewater

A technology of electroplating wastewater and treatment methods, which is applied in metallurgical wastewater treatment, multi-stage water treatment, heating water/sewage treatment, etc., can solve the problems of high cost of immobilized carriers, short service life, and many control conditions, and achieve design and construction Low cost, reduced material cost, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

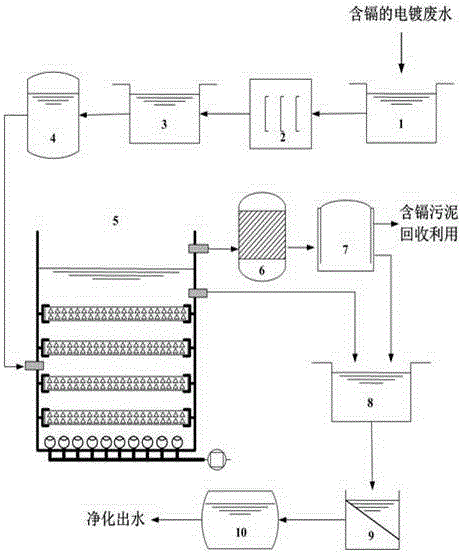

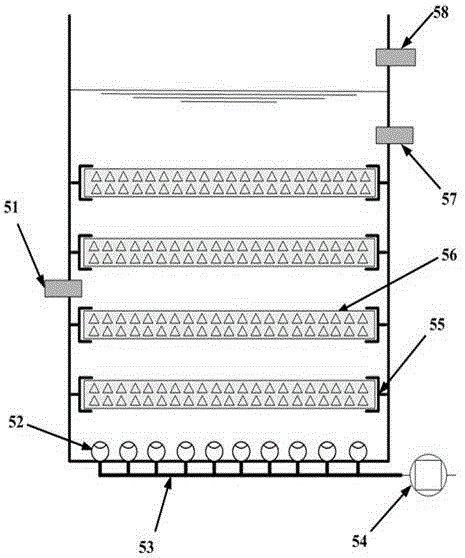

[0029] Such as figure 1 The treatment method for removing cadmium in the electroplating wastewater is shown. The electroplating wastewater containing cadmium enters the water collection well 1 through the wastewater pipeline, where it is collected and initially stabilized. The outlet of the water collection well 1 is connected to the coarse grid 2 through the wastewater pipeline. This removes large-diameter solid matter in the wastewater. The outlet of the coarse grid 2 is connected to the primary sedimentation tank 3 through the wastewater pipeline, where the insoluble substances in the wastewater are further removed. The outlet of the primary sedimentation tank 3 is connected to the pH adjustment tank 4 through the wastewater pipeline. , the pH value of the waste water is precisely adjusted here. The pH value range of the effluent of the pH value adjustment tank 4 is 5.5~6.5 to meet the pH value requirements of the tea meal-aeration flotation purification system 5. The pH val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com