Automatic equipment and method for achieving high-speed laser marking and discharging packaging

An automatic equipment and laser marking technology, applied in packaging and other fields, can solve problems such as the inability to achieve high-speed marking, the impracticality of large-scale nut production, and the limited transmission speed of the conveyor belt, achieving accurate counting, high counting accuracy, The effect of preventing scrolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] like Figure 2~6 As shown, the blanking slide rail 3 includes a mounting plate 9, a Y-shaped nylon slide rail 10 mounted on the mounting plate 9, a first material blocking mechanism 11, a second material blocking mechanism 12, and a third material blocking mechanism 13. The fourth blocking mechanism 14, the fifth blocking mechanism 15, the sixth blocking mechanism 16, the seventh blocking mechanism 17, the first clamping mechanism 18, the second clamping mechanism 19 and the counting storage mechanism 20, among which :

[0046] The upper end surface of the mounting plate 9 is a smooth stainless steel surface, and the side surface is provided with a concave height adjusting groove 27 .

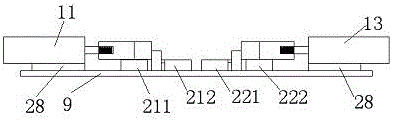

[0047] The Y-shaped nylon slide rail 10 is composed of a first feeding slide rail 21 , a second feeding slide rail 22 , a first buffer slide rail 24 , a second buffer slide rail 25 and a discharging slide rail 23 . One end of the feeding slide rail 21 is connected to an outlet of the v...

Embodiment 2

[0058] like Figure 7~9 As shown, the technical difference between this embodiment and Embodiment 1 lies in the Y-shaped nylon slide rail. In this embodiment, the Y-shaped nylon slide rail 10 consists of a first feeding slide rail 21', a second feeding slide rail 22', A buffer slide rail 24', a second buffer slide rail 25' and an unloading slide rail 23' are composed, wherein one end of the first feeding slide rail 21' is connected to an outlet of the vibrating plate, and the other end is connected to the first buffer slide rail 24' After connecting to the unloading slide rail 23', one end of the second feeding slide rail 22' is connected to another outlet of the vibrating plate, and the other end is connected to the second buffer slide rail 25' and then connected to the unloading slide rail 23'.

[0059] The first feeding slide rail 21' is composed of a first left baffle 211' and a first right baffle 212'. The first left baffle 211' and the first right baffle 212' have multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com