9Ni steel and stainless steel composite steel plate for LNG storage tank and movable vessel and manufacturing method of composite steel plate

A composite steel plate and manufacturing method technology, applied in the field of hot-rolled steel plate production, can solve the problems of easy rusting of steel plate, easy magnetization of 9Ni steel plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078]In the prior art, the 160,000 m3 LNG storage tank inner tank wall is made of a 27mm thick simple 9Ni steel plate, and the selected grade is 06Ni9DR in GB3531-2014. The steel plate of this grade requires the average Charpy impact energy at -196°C to be ≥100J, the impact energy of a single sample should be ≥80J, the cold bending test (3a) is qualified, the tensile strength of the steel plate should be between 680-820MPa, and the yield strength should be ≥560MPa. Elongation after breaking ≥ 18%.

[0079] In this embodiment, a 160,000-cubic-meter LNG tank inner tank is designed with a 3-layer composite steel plate of stainless steel / 9Ni steel / stainless steel used for the first wall plate.

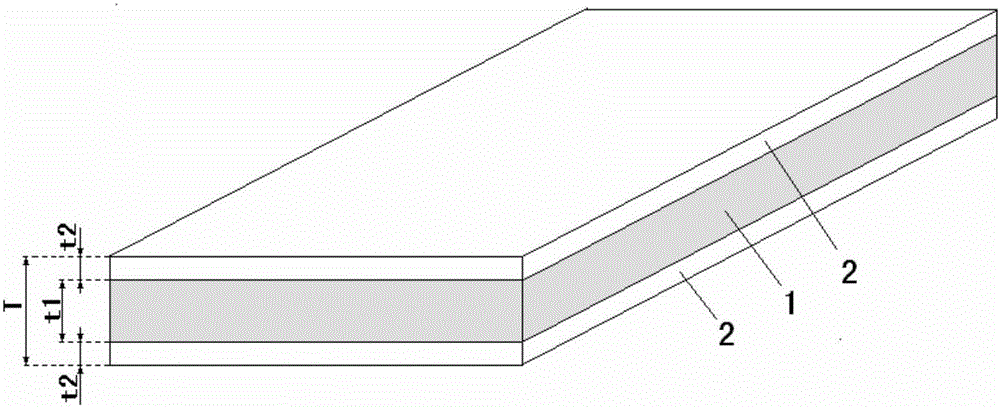

[0080] In this embodiment, the first ring wall plate of the 160,000 m3 LNG storage tank inner tank will be designed as a 27mm thick stainless steel / 9Ni steel / stainless steel 3-layer composite steel plate, such as figure 1 As shown, among them, the thickness t1 of the 9Ni steel base layer...

Embodiment 2

[0106] In the prior art, a certain type of vehicle-mounted mobile LNG container was originally designed to use pure 9Ni steel plates with a thickness of 8mm, and the selected brand was X8Ni9 in EN10028-4. The steel plate of this grade requires that the transverse Charpy impact energy (converted into a 10×10mm impact specimen) at -196°C should be ≥100J on average, and the impact energy of a single specimen should be ≥80J. The strength should be between 680 and 820MPa, the yield strength should be ≤585MPa, and the elongation after fracture should be ≤18%.

[0107] In this embodiment, this type of vehicle-mounted mobile LNG container will be designed to adopt a 3-layer composite steel plate with a thickness of 8mm stainless steel / 9Ni steel / stainless steel, such as figure 1 As shown, among them, the thickness t1 of the 9Ni steel base layer 1 is 7 mm, and the material is X8Ni9 in EN10028-4; the thickness t2 of the stainless steel cladding layer 2 is 0.5 mm, and the material is aust...

Embodiment 3

[0131] In the prior art, a certain type of vehicle-mounted mobile LNG container was originally designed to use a 5mm thick pure 9Ni steel plate, and the selected brand was X8Ni9 in EN10028-4. The steel plate of this grade requires that the transverse Charpy impact energy (converted into a 10×10mm impact specimen) at -196°C should be ≥100J on average, and the impact energy of a single specimen should be ≥80J. The strength should be between 680 and 820MPa, the yield strength should be ≥585MPa, and the elongation after fracture should be ≥18%.

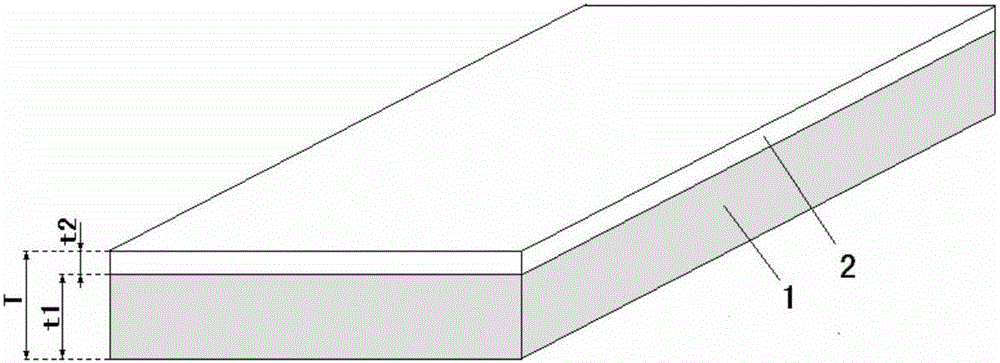

[0132] In this embodiment, this type of vehicle-mounted mobile LNG container will be designed to adopt a 2-layer composite steel plate of 9Ni steel / stainless steel with a thickness of 5mm, such as image 3 As shown, among them, the thickness t1 of the 9Ni steel base layer 1 is 4.5 mm, and the material is X8Ni9 in EN10028-4; the thickness t2 of the stainless steel cladding layer 2 is 0.5 mm, and the material is austenitic stainless steel S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com