A kind of water-based aluminum alloy die-casting mold release agent and preparation method thereof

A technology of aluminum alloy and mold release agent, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of unstable product quality of emulsion, unsatisfactory emulsification effect, poor film finish, etc., and achieve mold release effect Excellent, improves smoothness and integrity, easy emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

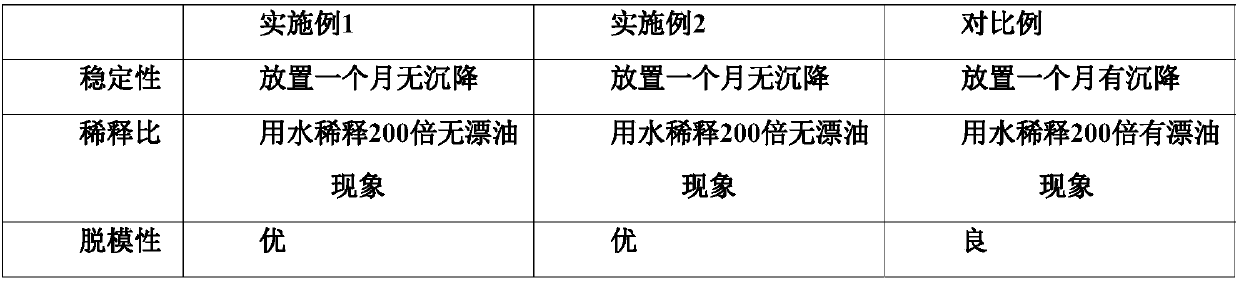

Examples

Embodiment 1

[0026] The composition of the water-based release agent according to the mass ratio is: 100 parts of long-alkane-chain phenyl-modified silicone oil, 10 parts of oxidized polyethylene wax with a melting point of 100-120 ° C, 10 parts of isomeric decanol polyoxyethylene ether, 8 parts AEO9, 10 parts Tween 80, 500 parts deionized water.

[0027] Mix long-chain phenyl-modified silicone oil, oxidized polyethylene wax, isomerized decanol polyoxyethylene ether, long-chain fatty alcohol polyoxyethylene ether, Tween, and heat to melt the above components, and 2000 Stir at -3000 rpm for half an hour, cool down to about 60°C, then slowly drop in deionized water in batches, and stir for another half an hour to prepare.

Embodiment 2

[0029] The composition of the water-based mold release agent according to the mass ratio is: 150 parts of long alkyl chain phenyl modified silicone oil, 15 parts of oxidized polyethylene wax at 98-100 ° C, 15 parts of isomeric decanol polyoxyethylene ether, 10 parts AEO9, 10 parts Tween 80, 700 parts deionized water.

[0030] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com