Thick raspberry pulp and preparation method thereof

A technology for thick pulp and raspberry, which is applied in the directions of food ingredients as thickeners, food ingredients as taste improvers, food ingredients as odor improvers, etc., can solve the problem that the color, aroma and aroma substances of raspberries cannot be well preserved. For problems such as thermal instability and reducing the appearance of food, it achieves the effect of bright color, both edible value and health value, and reducing the oxidation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

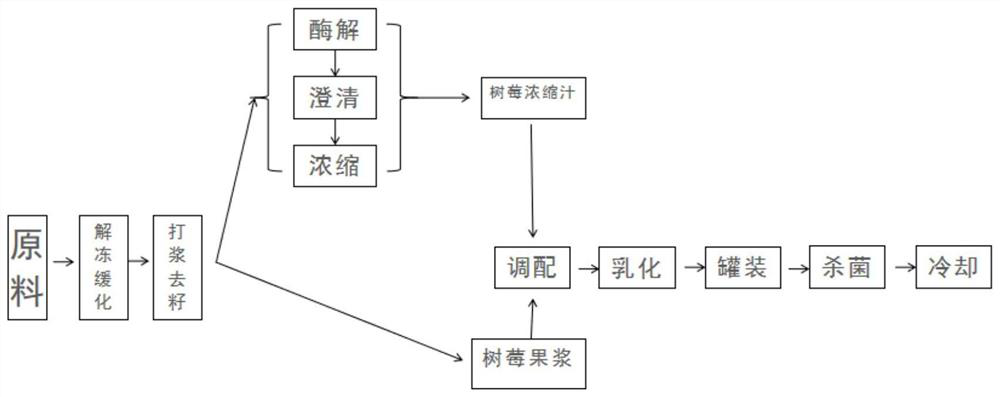

Method used

Image

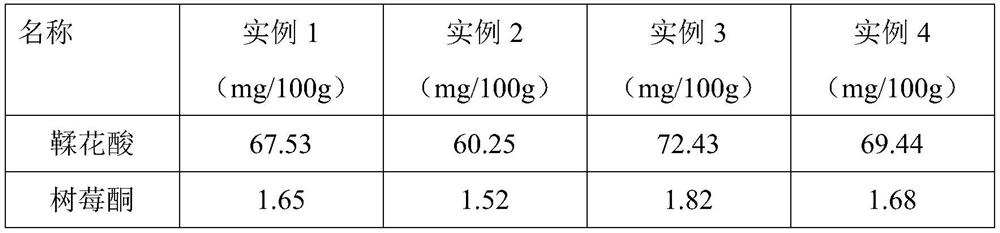

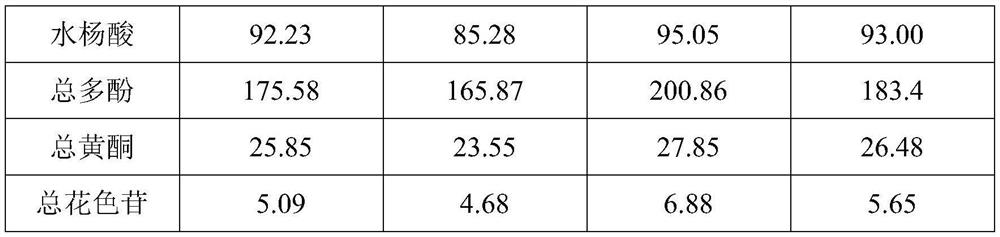

Examples

Embodiment 1

[0054] A kind of raspberry thick pulp, the raw material of described thick pulp comprises red raspberry pulp, black raspberry pulp, red raspberry clear juice concentrated juice, black raspberry clear juice concentrated juice, white granulated sugar, pectin, carboxymethyl fiber Vegetarian Sodium.

[0055] Red raspberry pulp is 20 parts by weight, black raspberry pulp is 10 parts by weight, red raspberry clear juice concentrated juice is 20 parts by weight, black raspberry clear juice concentrated juice is 10 parts by weight, pectin addition is 0.2 parts, and the addition amount of sodium carboxymethyl cellulose is 0.3 parts. Processing aids: compound enzyme preparation of pectinase and cellulase, the enzyme addition amount is 40 mg / L; the clarification agent addition amount is 0.01 part.

[0056] The preparation steps of this kind of raspberry thick pulp are:

[0057] 1. Preparation of Red / Black Raspberry Puree

[0058] Take out the frozen red / black raspberry jelly fruit, an...

Embodiment 2

[0067] A kind of red raspberry thick pulp, the raw material of described thick pulp comprises red raspberry pulp, red raspberry clear juice concentrated juice, white granulated sugar, pectin.

[0068] The weight part of the red raspberry pulp is 20 parts, the weight part of the red raspberry clear juice concentrate is 15 parts, and the added amount of pectin is 0.6 parts. Processing aids: compound enzyme preparations of pectinase and cellulase, the enzyme addition amount is 80mg / L; the clarification agent addition amount is 0.05 parts.

[0069] The preparation steps of this kind of raspberry thick pulp are:

[0070] 1. Preparation of Red Raspberry Puree

[0071] Take out the frozen red raspberry jelly fruit, and slow down completely within 12 hours. The red raspberry jelly fruit is processed by a beater, and a 0.45mm perforated filter is built in the beater, and the fruit seeds are removed after filtering to obtain red raspberry pulp.

[0072] 2. Preparation of red raspberry...

Embodiment 3

[0080] A thick blackberry pulp, the raw materials of the thick pulp include blackberry fruit pulp, blackberry clear juice concentrate, white granulated sugar, and sodium carboxymethylcellulose.

[0081] The blackberry pulp is 30 parts by weight, the blackberry clear juice concentrate is 15 parts by weight, and the added amount of sodium carboxymethylcellulose is 0.05 parts. Processing aids: compound enzyme preparations of pectinase and cellulase, the enzyme addition amount is 80mg / L; the clarification agent addition amount is 0.05 parts.

[0082] The preparation steps of this kind of raspberry beverage concentrated slurry are:

[0083] 1. Prepare blackberry puree

[0084] Take out the frozen blackberry jelly fruit, and slow down completely within 12 hours. The blackberry jelly fruit is processed by a beater, and a 0.5mm perforated filter is built in the beater, and the seeds are removed after filtering to obtain blackberry pulp.

[0085] 2. Prepare blackberry clear juice con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com