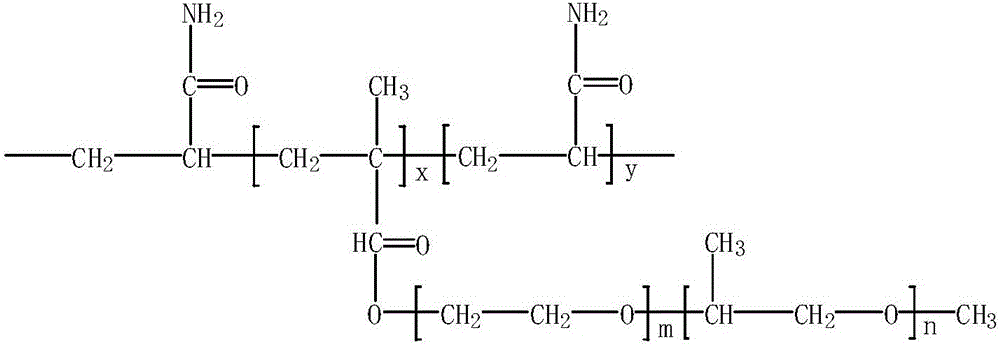

Comb-shaped polyacrylamide crystal growth disrupting agent, crystallization-resistant type tail gas catalytic reducing agent prepared from disrupting agent and preparation method

The technology of polyacrylamide and interfering agent is applied in the field of anti-crystallization type tail gas catalytic reducing agent and its preparation field, which can solve the problems of crystallization blockage at pipeline vortex, pipeline crystallization, nozzle blockage and the like, and achieves a simple, easy, and prolonged preparation method. Red light cycle, the effect of reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The composition distribution ratio of the anti-crystallization catalytic reducing agent is shown in Table 1.

[0018] The composition table of table 1 catalytic reducing agent

[0019] components

Mass percentage / %

Mass / kg

Adblue

95.855

47.927

crystal growth disruptor

0.010

0.005

4.000

2.000

pure water

0.135

0.068

total

100

50

[0020] Wherein, m=35, n=15, x=10, x:y=1:18.

[0021] The preparation steps of the present invention are as follows: (1) dissolving: add Adblue, crystal growth disruptor and triethanolamine respectively in the dissolving tank according to the ratio in Table 1, mix and stir, and make the tail gas catalytic reducing agent primary product; (2) Purification: filter and purify the first product of the tail gas catalytic reduction agent through a bag filter with a filtration accuracy of 10 microns, and the filtration flow rate is 2m 3 / H...

Embodiment 2

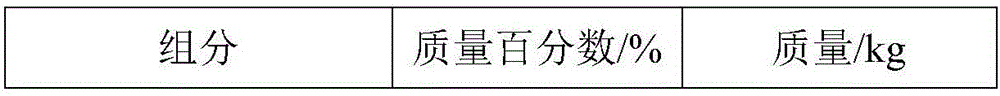

[0023] The component distribution ratio of anti-crystallization type catalytic reducing agent is shown in table 2

[0024] The composition table of table 2 catalytic reducing agent

[0025]

[0026]

[0027] Wherein, m=30, n=10, x=12, x:y=1:16.

[0028] The preparation steps are as follows: (1) Dissolving: add Adblue, crystal growth disruptor and ethanolamine respectively into the dissolving tank according to the proportions in Table 2, mix and stir to prepare the primary tail gas catalytic reducer; (2) Purify: dissolve the The primary product of the tail gas catalytic reduction agent is filtered and purified through a mechanical filter, and the filtration flow rate is 3m 3 / H to obtain the filtered tail gas catalytic reductant, and then carry out membrane separation by NF technology to obtain the separated tail gas catalytic reductant; (3) make: add 2.776kg of pure water in metering, adjust its total nitrogen content to be 0.155, and make A crystalline tail gas cataly...

Embodiment 3

[0030] The component distribution ratio of anti-crystallization type catalytic reducing agent is shown in table 3

[0031] The composition table of table 3 catalytic reducing agent

[0032] components

Mass percentage / %

Mass / kg

Adblue

86.182

43.091

crystal growth disruptor

1.000

0.500

10.000

5.000

Ultra-pure water

2.818

1.409

total

100

50

[0033] Wherein, m=40, n=20, x=8, x:y=1:20.

[0034] The preparation steps are as follows: (1) Dissolving: Add Adblue, crystal growth disruptor and monoisopropanolamine into the dissolving tank respectively according to the proportions in Table 3, mix and stir to make the primary exhaust gas catalytic reducer; (2) Purification: filter and purify the exhaust gas catalytic reducing agent primary product through a precision filter element filter with a filtration accuracy of 0.45 microns to obtain the filtered exhaust catalyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com