Preparation method for tobacco source raw material with basic cigarette smell

A tobacco and raw material technology, applied in the field of tobacco, can solve problems such as lack of aroma, unnaturalness, and insufficient aroma harmony, and achieve the effect of ensuring appearance and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

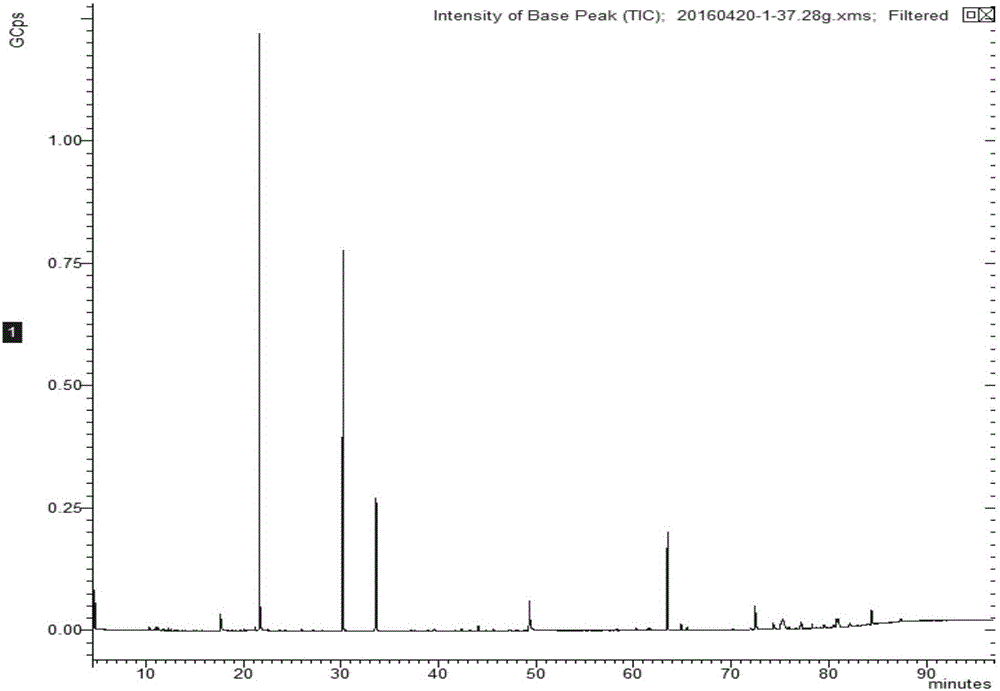

[0043] Cut the middle leaf group of self-prepared flue-cured tobacco twice with a shredder, weigh 70 grams into a 1000ml round bottom flask, add a composite solvent consisting of 350 grams of ethanol, 50 grams of n-hexane, and 70 grams of ethyl acetate and stir at 60 °C Reflux and extract for 2.5 hours, release the extract and filter, concentrate under reduced pressure (50°C, -0.095MPa) to dryness, and then dissolve and extract the dry product with a composite solvent composed of 30 grams of ethyl acetate and 20 grams of dichloromethane for 30 minutes, then filter Obtain the filtrate, and the filtrate is concentrated to dryness under reduced pressure in the same way, and after removing residual ethyl acetate and dichloromethane through absolute ethanol twice, obtain 37.28 grams of ethanol as a solvent for extracting agent (number is 20160420-1, its aroma The total ion chromatogram of the components detected by GC / MS is shown in figure 1 ). The filter residue was dried in an o...

Embodiment 2

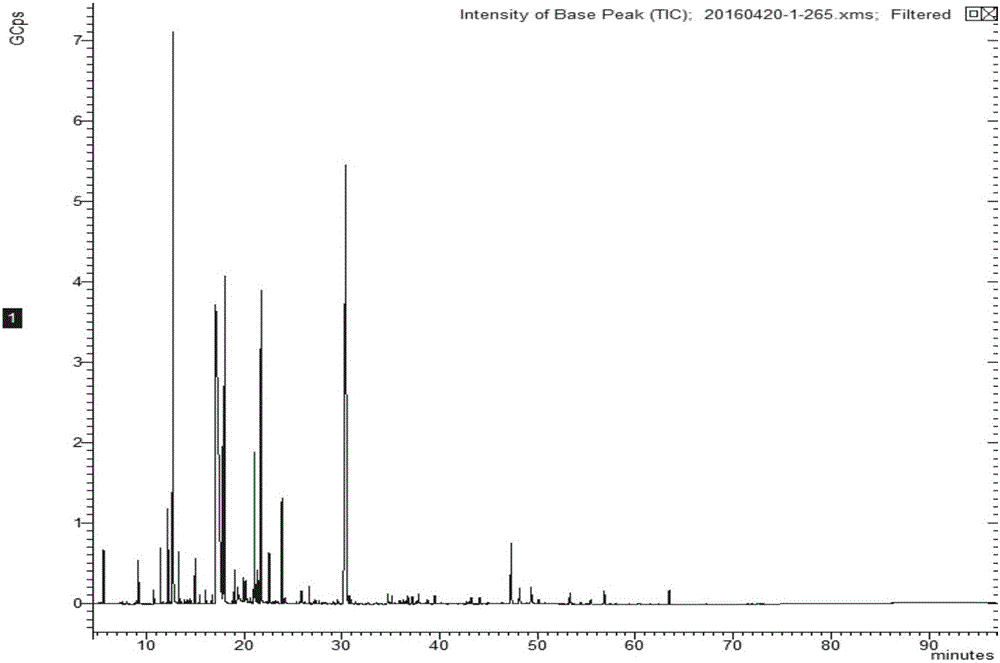

[0068] Grind Zimbabwe 2011 L1OF flue-cured tobacco into powder and pass through a 40-mesh sieve, weigh 102 grams into a 1000ml round bottom flask, add 303 grams of ethanol, 125 grams of deionized water, and 70 grams of ethyl acetate and stir at reflux at 60°C Extract for 3 hours, release the extract, filter, concentrate under reduced pressure (60°C, -0.095MPa) to dryness, and then stir and dissolve the obtained dry matter in a composite solvent composed of 41.2 grams of ethyl acetate and 40 grams of chloroform, extract for 30 minutes, and then filter to obtain the filtrate , the filtrate was concentrated to dryness under reduced pressure in the same way, and after removing the residual ethyl acetate and chloroform through two dehydrated ethanols, 29.5 grams of ethanol as a solvent for the extraction agent (number 20160420-2, whose aroma components were obtained by The total ion chromatogram detected by GC / MS is shown in Figure 4 ). The filter residue was dried in an oven at ...

Embodiment 3

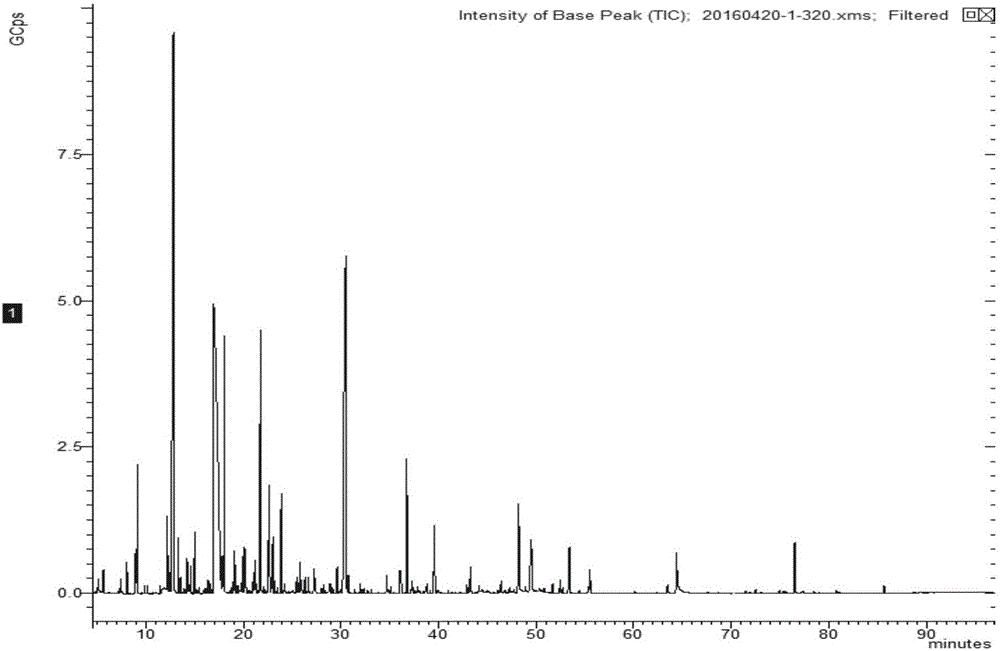

[0071] Put 121 grams of upper flue-cured tobacco B3F tobacco powder (40 mesh) produced in Hunan Jiangyong in 2010 in a 1000ml round bottom flask, add a composite solvent composed of 459 grams of ethanol, 103 grams of deionized water, and 82 grams of cyclohexane at 60 ° C. Stir and reflux for extraction for 3 hours, discharge the extract and filter, concentrate under reduced pressure (60°C, -0.095MPa) to dryness, and then dissolve the obtained dry matter in 109.4 g of dichloromethane with stirring and dissolving for 30 minutes, then filter to obtain the filtrate, which is concentrated to dryness under reduced pressure in the same way , and after twice dehydrated alcohol removes residual methylene chloride, obtains the extraction agent 34.72 grams (numbering is 20160420-3 of ethanol as solvent, and the total ion chromatogram that its aroma component detects through GC / MS sees Figure 6 ). The filter residue was dried in an oven at 60°C for 2 hours and then taken out. Pre-set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com