Valve seat and spiral planar inlet nozzle

A valve seat, nozzle hole technology, applied in the direction of spray device, spray device, etc., can solve the problems of affecting the spray effect, blocking the nozzle hole, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

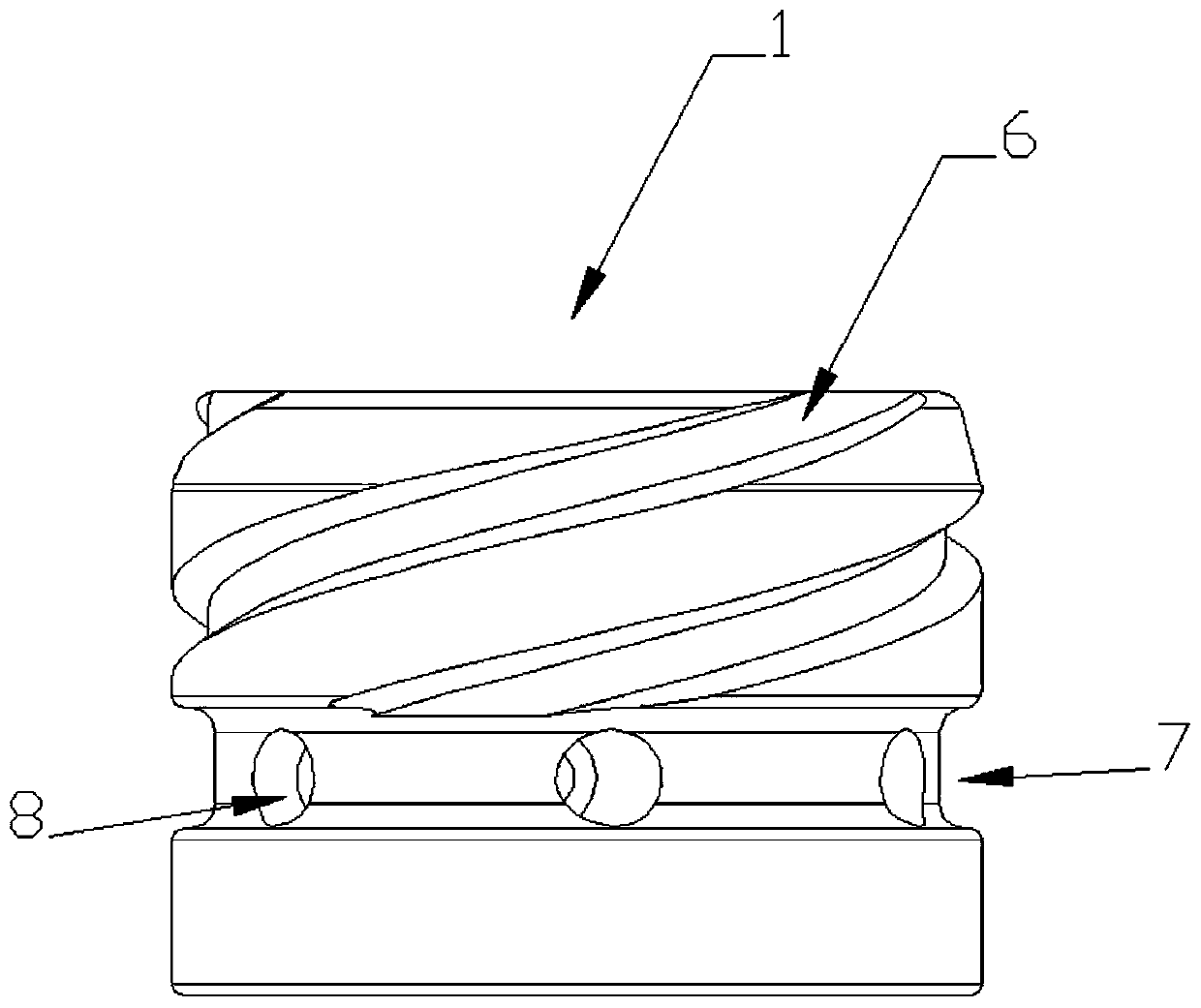

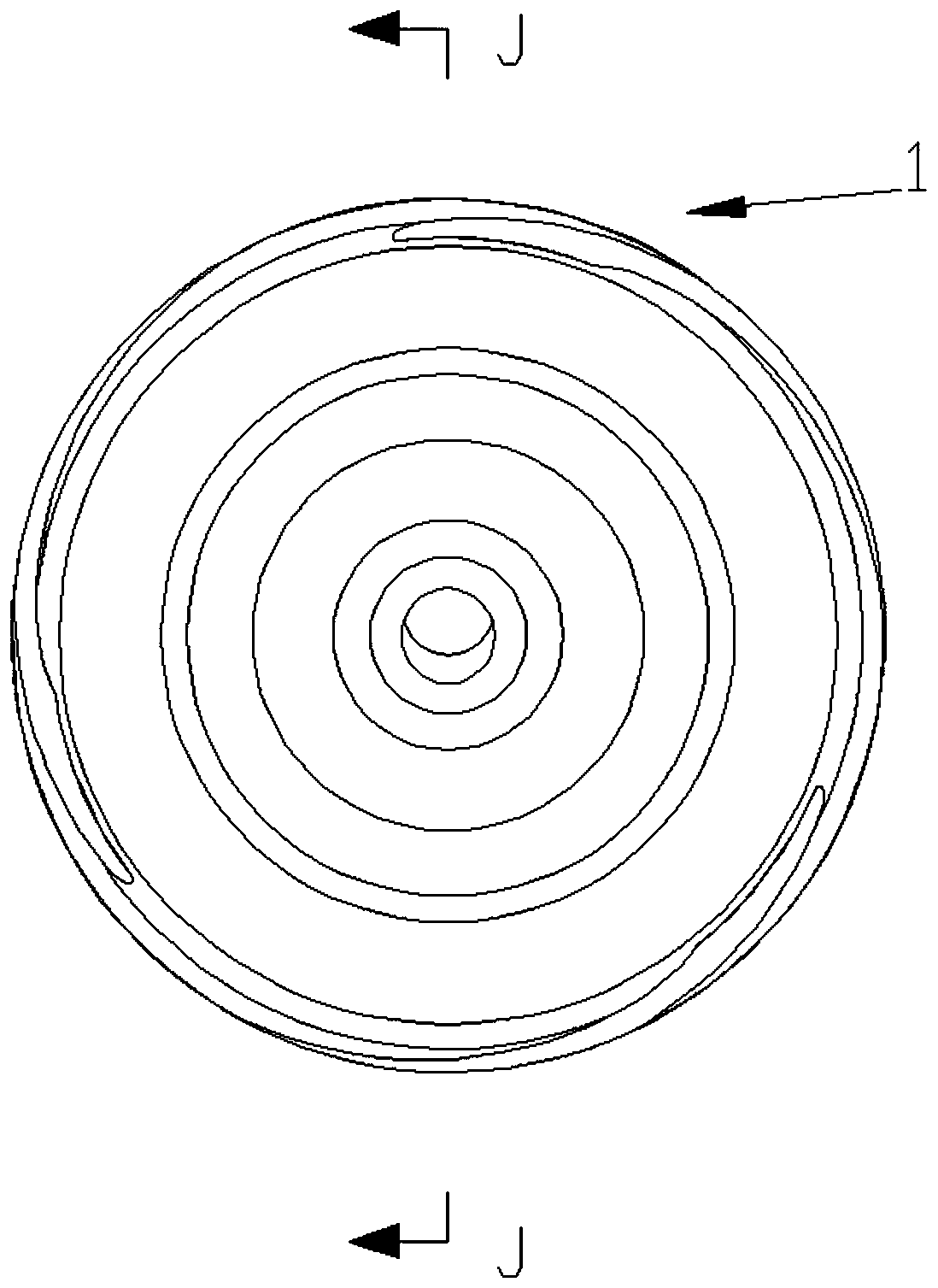

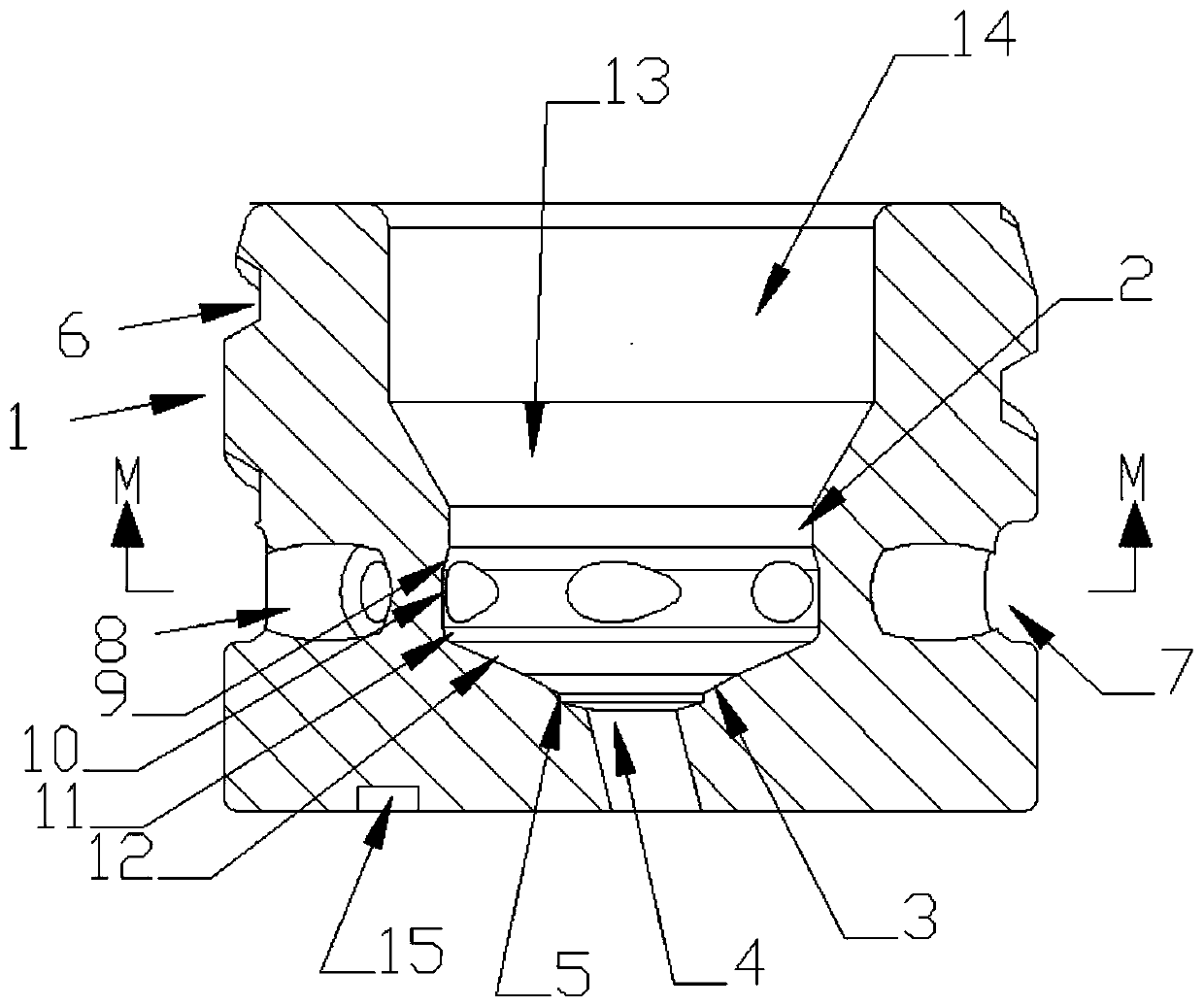

[0030] Such as Figure 1-5As shown, this embodiment discloses a valve seat, which includes: a valve seat main body 1, the shape of the valve seat main body 1 is not limited, as long as it can cooperate with the structure of the nozzle (especially at the installation position of the nozzle) to realize the nozzle function, such as oil pipe body, in this embodiment, the valve seat body 1 can be regular shape, also can be irregular shape, preferably the cylinder structure in the regular shape, more preferably cylinder; The seat main body 1 is provided with a first cylindrical chamber 2, a swirl chamber, a first sealing chamber 3 and a nozzle hole 4 which communicate with each other. During use, the first cylindrical chamber 2 is in sliding contact with the sphere as much as possible to ensure The valve core does not skew when the ball slides, and the swirl chamber is arranged below the first cylindrical chamber 2, and its shape is not specifically limited, and it can be a regular ...

Embodiment 2

[0035] Such as Image 6 with Figure 7 As shown, this embodiment discloses a spiral flat-in nozzle, which includes an oil pipe body 18, and the lower end of the oil pipe body 18 is socketed with the outer surface of the valve seat body 1 of the valve seat, so that the fluid flows in the spiral The groove 6 and the diversion groove 7 combine with the inner wall of the lower end of the oil pipe body 18 to form a closed fluid channel. After the fluid enters through the upper end of the spiral groove 6, the fluid has more impact and stability when rotating and flowing. The valve seat is the valve seat structure in Embodiment 1; it also includes a valve core 16, and the lower end of the valve core 16 is connected with a ball 17, and the ball 17 can be an existing ball of any shape, which can be a whole ball or a ball. It may be a partial sphere, and the sphere 17 cooperates with the first sealed cavity 3 to realize the spraying of the nozzle.

[0036] In addition, other structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com