Preparation method for three-dimensional aminated carbon nanotube array/stretchable textile fiber electrode material

A technology of three-dimensional amidated carbon and nanotube arrays, which is applied in the field of electrochemical materials, can solve the problems of building three-dimensional flexible conductive materials, etc., and achieve the effects of good electrical conductivity, increased adsorption capacity, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

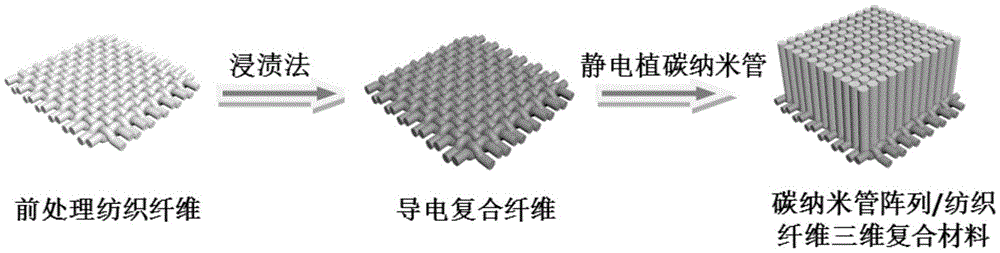

Method used

Image

Examples

Embodiment 1

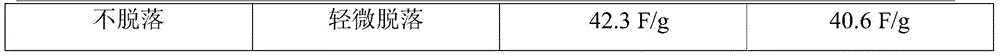

[0046] After the pretreatment, the high-content cationic modified polyester / spandex blended knitted jersey was immersed in the composite preparation solution containing sodium dodecylbenzenesulfonate (10g / L) and aminated carbon nanotubes (1.6g / L). Immersed at room temperature for 5 minutes, dried at 120°C, and repeated 5 times to obtain a conductive stretchable fiber substrate. Place the aminated carbon nanotubes in the electrodeposition treatment solution (mass fraction: potassium aluminum sulfate 6%, sodium silicate 3%, dispersant NNO 15%, penetrant JFC 4%), heat up to 60°C, bath ratio 50:1 , time is 60min, vacuum filtration and drying. The prepared conductive stretchable fiber substrate is evenly coated with graphene conductive adhesive, and the aminated carbon nanotubes that have been electro-treated are electrostatically implanted on the surface of the substrate on one side, the voltage is 50KV, and the distance between the plates is 120mm. for 5s. After implantation, p...

Embodiment 2

[0050] After the pretreatment, the high-content cationic modified polyester / spandex blended knitted jersey was immersed in the composite preparation solution containing sodium dodecylbenzenesulfonate (15g / L) and aminated carbon nanotubes (1.6g / L). Immersed at room temperature for 5 minutes, dried at 120°C, and repeated 5 times to obtain a conductive stretchable fiber substrate. Place the aminated carbon nanotubes in the electrodeposition treatment solution (mass fraction: aluminum potassium sulfate 8%, sodium silicate 4%, dispersant NNO 20%, penetrant JFC 4%), heat up to 60 ° C, bath ratio 50:1 , time is 60min, vacuum filtration and drying. The prepared conductive stretchable fiber substrate is uniformly coated with graphene conductive glue, and the aminated carbon nanotubes that have been electro-treated are implanted on the surface of the substrate electrostatically on one side, the voltage is 50KV, and the distance between the plates is 140mm. for 5s. After implantation, ...

Embodiment 3

[0054] After the pretreatment, the high-content cationic modified polyester / spandex blended knitted jersey was immersed in the composite preparation solution containing sodium dodecylbenzenesulfonate (15g / L) and aminated carbon nanotubes (1.6g / L). Immersed at room temperature for 5 minutes, dried at 120°C, and repeated 8 times to obtain a conductive stretchable fiber substrate. Place the aminated carbon nanotubes in the electrodeposition treatment solution (mass fraction: potassium aluminum sulfate 8%, sodium silicate 5%, dispersant NNO 15%, penetrant JFC 6%), heat up to 60°C, bath ratio 50:1 , time is 60min, vacuum filtration and drying. The prepared conductive stretchable fiber substrate is evenly coated with graphene conductive adhesive, and the aminated carbon nanotubes that have been electro-treated are electrostatically implanted on the surface of the substrate on one side, the voltage is 50KV, and the distance between the plates is 120mm. for 5s. After implantation, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com