Feed circuit based on IMPATT diode

A technology of feeding circuit and feeding column, which is applied in the field of radar, can solve problems such as separate consideration, achieve the effect of preventing mutual interference and improving debuggability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

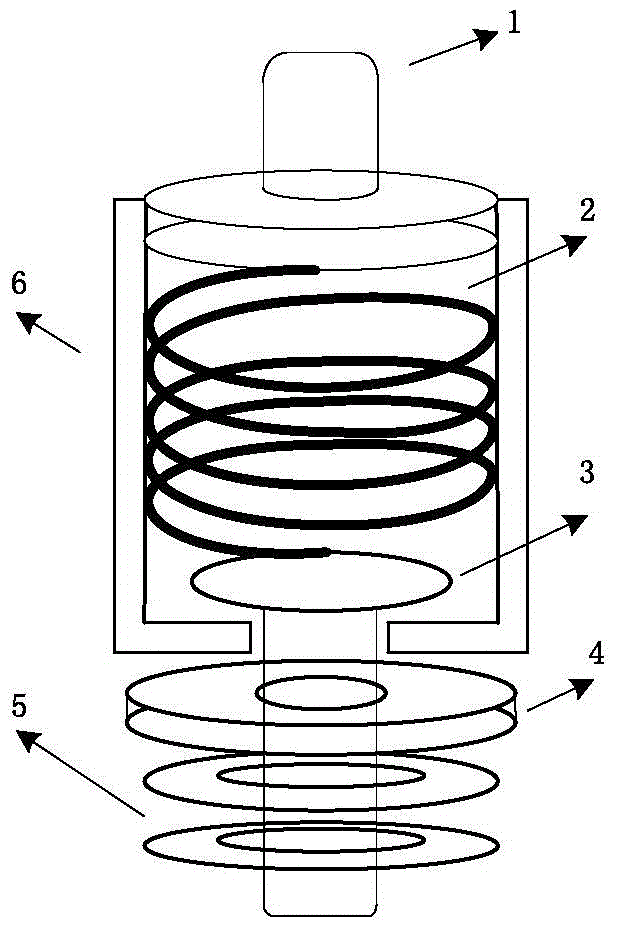

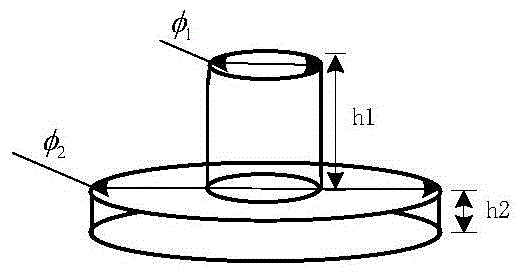

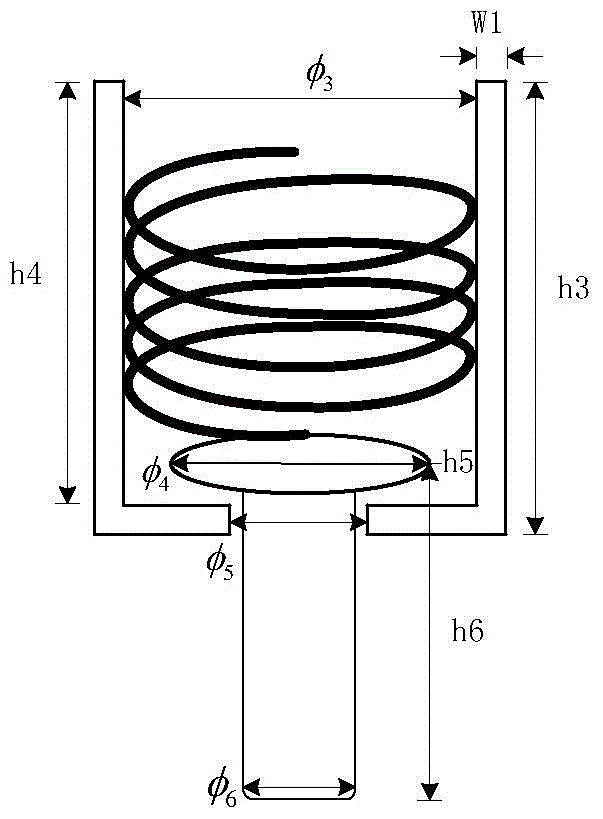

[0026] The overall structure of the feed circuit based on the IMPATT tube is shown as figure 1 As shown, the whole circuit is composed of upper feed column, spring, lower feed column, insulating pad, metal ring and cavity. The upper and lower feed columns are respectively composed of a column and a chassis. The upper column and the external signal are welded to realize the signal feed-in. The lower column is in direct contact with the IMPATT tube to provide a bias signal for the tube. The upper and lower The chassis of the feeding column is relatively placed in the cavity, and a spring is added between the chassis of the upper and lower feeding columns, so that the lower feeding column can generate a corresponding displacement according to the magnitude of the moment. This design, on the one hand, enables the external DC bias signal to be directly fed into the circuit, on the other hand, it can meet the special debugging requirements that require the IMPATT tube to be able t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com