Gas blast circuit breaker

A technology for compressing gas and circuit breakers, which is applied to high-pressure air circuit breakers, circuits, electrical components, etc., and can solve problems such as overpressure valve wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

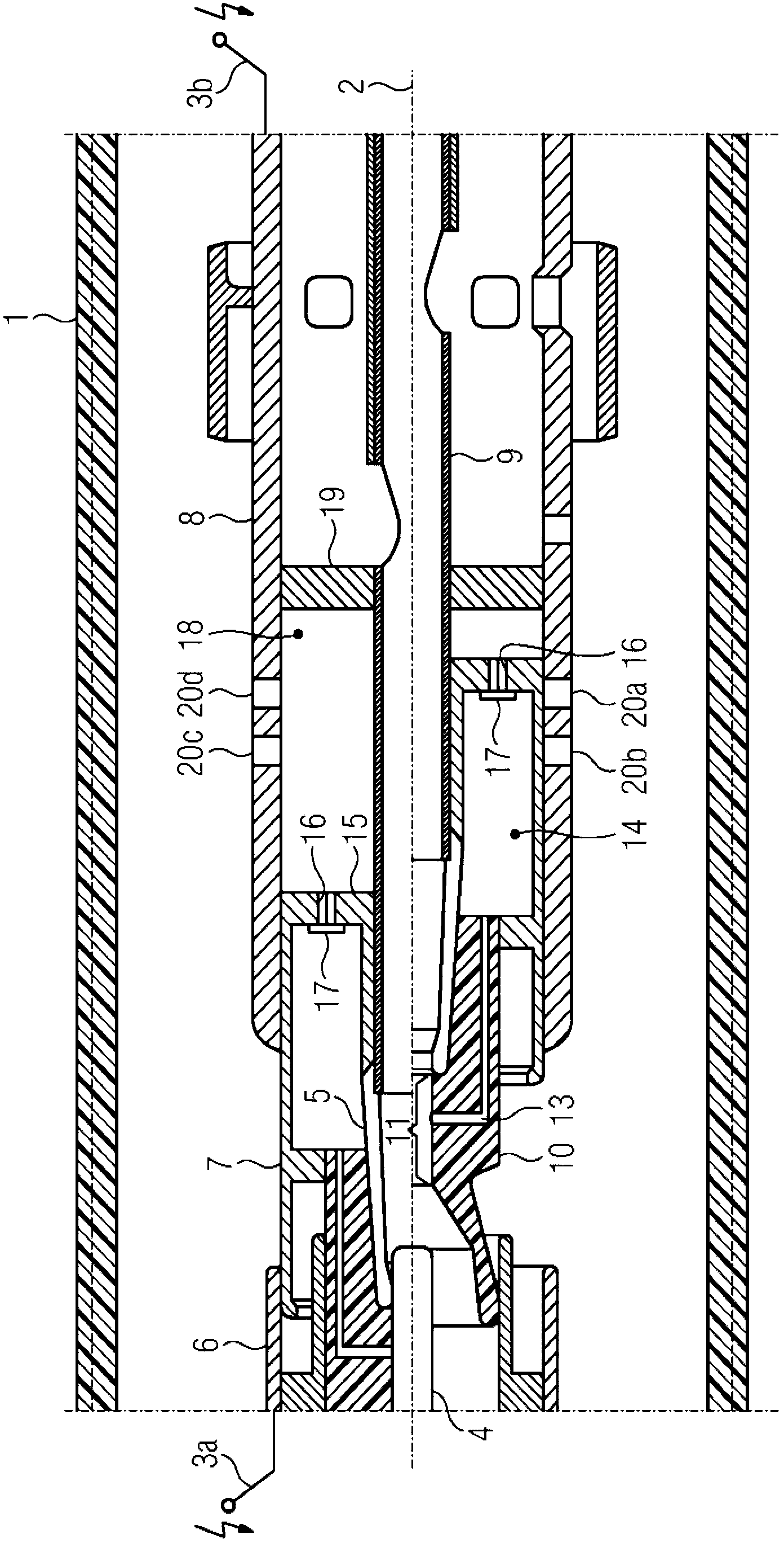

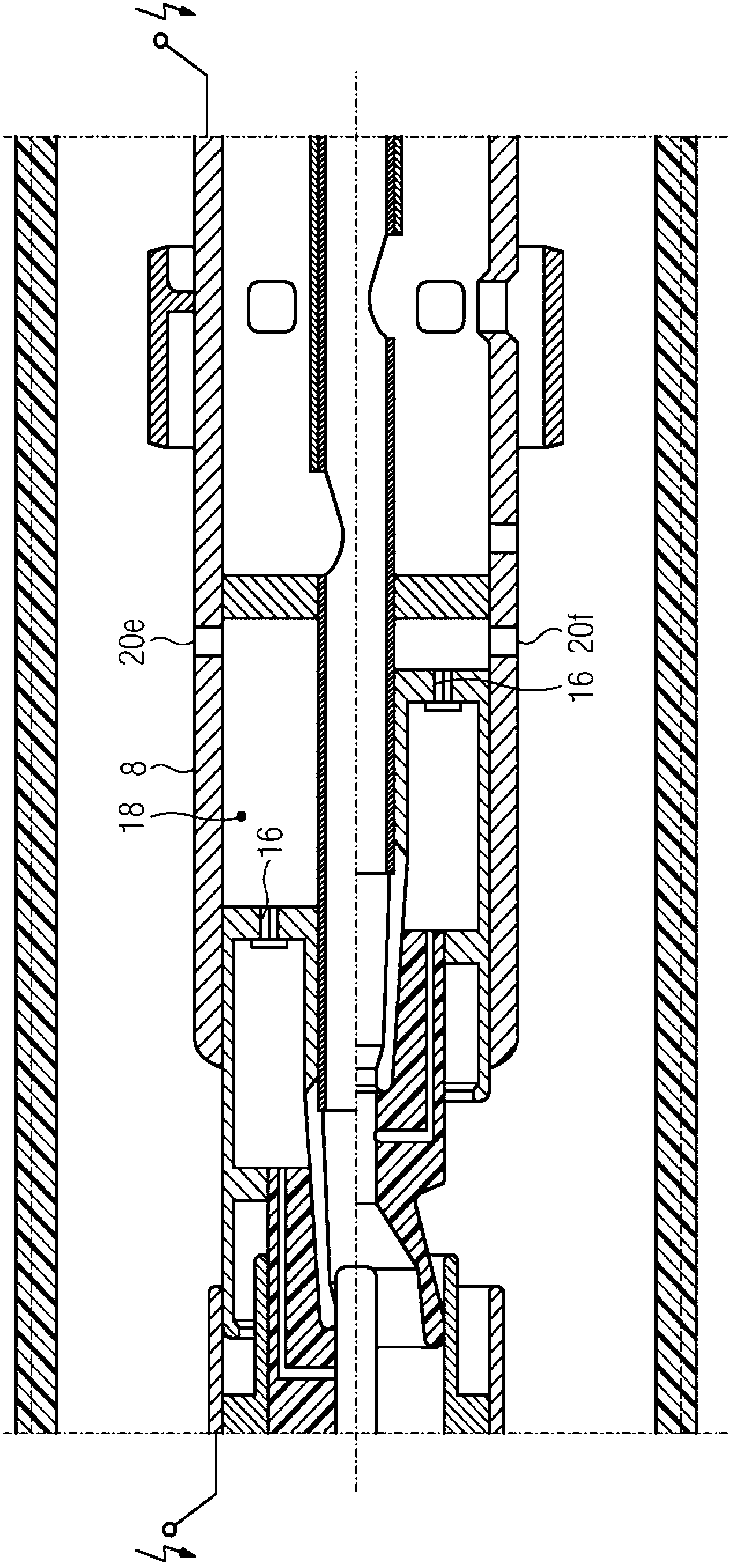

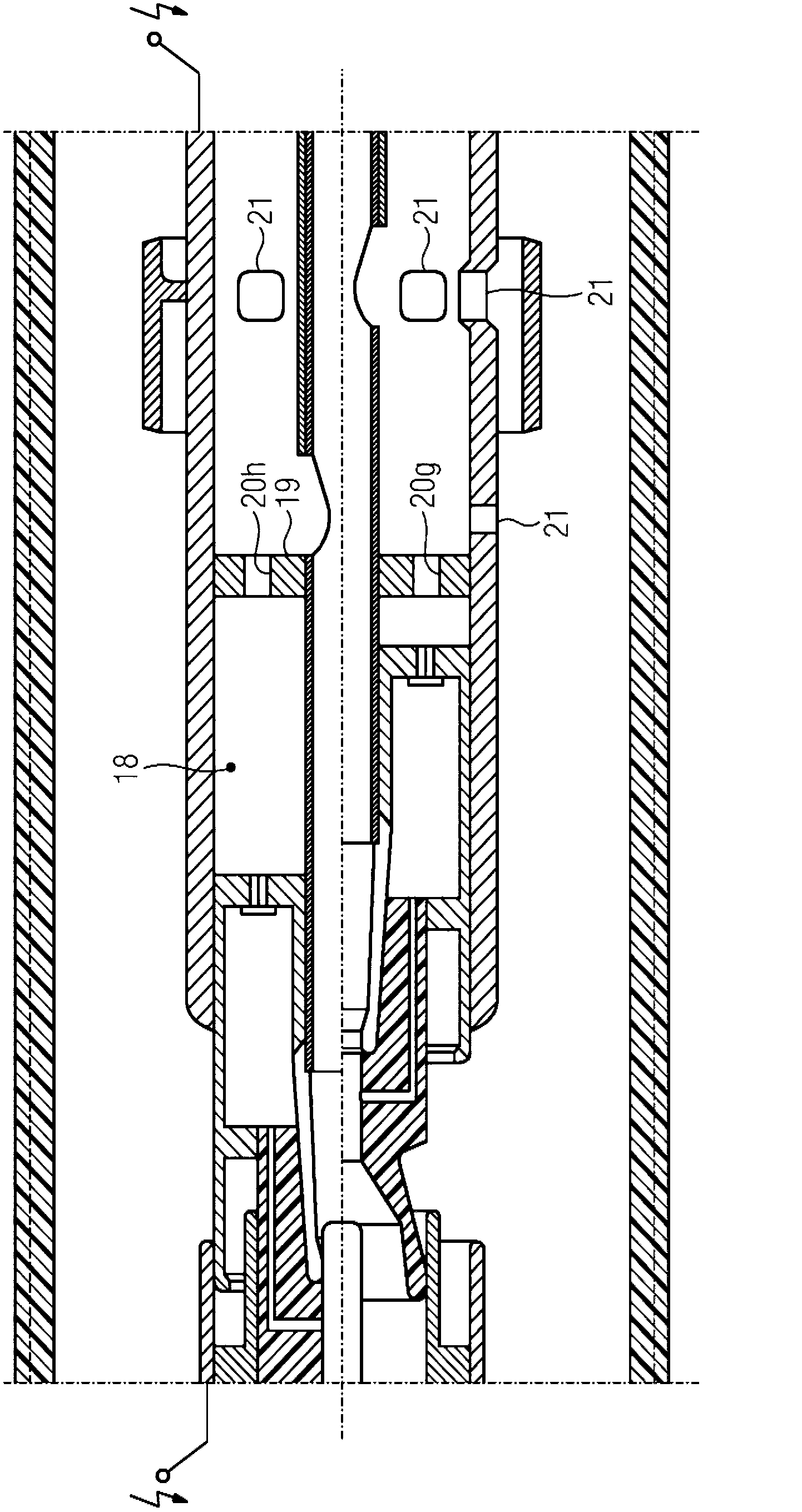

[0037] First, for example for figure 1 , figure 2 with image 3 Explain the structure and mode of action of compressed gas circuit breakers. Here at figure 1 , figure 2 with image 3 The same reference numerals are used for the same type of structural parts, and alternative reference numerals are used only for mutually different details.

[0038] What all three figures have in common is that the symmetry axis 2 divides the figure into a first half and a second half. The drawings respectively show the on state of the compressed gas circuit breaker in the first half of the figure and the open state of the compressed gas circuit breaker in the second half of the figure.

[0039] figure 1 The cross-section of the compressed gas circuit breaker is shown in the cross-sectional view. The compressed gas circuit breaker has an enclosure 1. The packaging housing 1 is here configured to be substantially tubular and oriented coaxially to the axis of symmetry 2. Here, the packaging case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com