Compressed gas circuit breaker

A technology for compressing gas and circuit breakers, which is applied to high-pressure air circuit breakers, circuits, electrical components, etc., and can solve problems such as overpressure valve wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

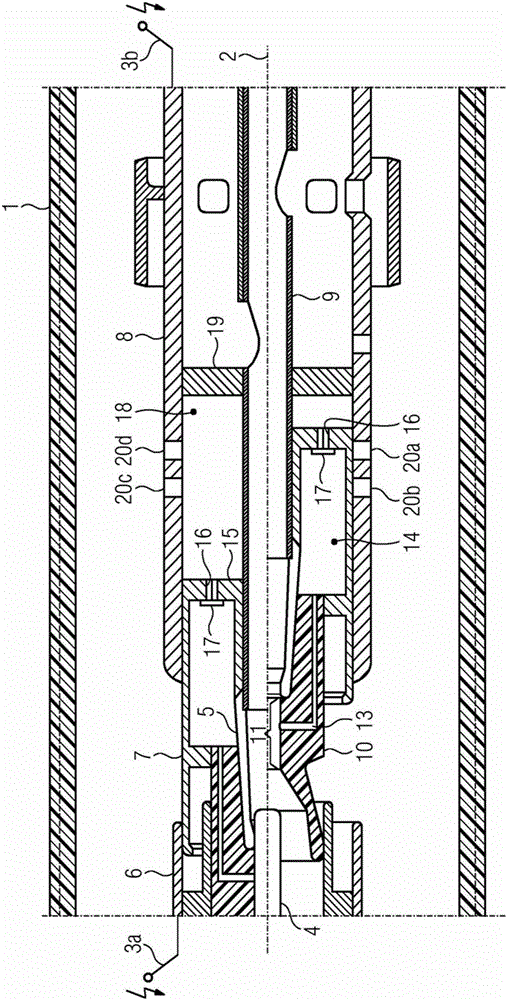

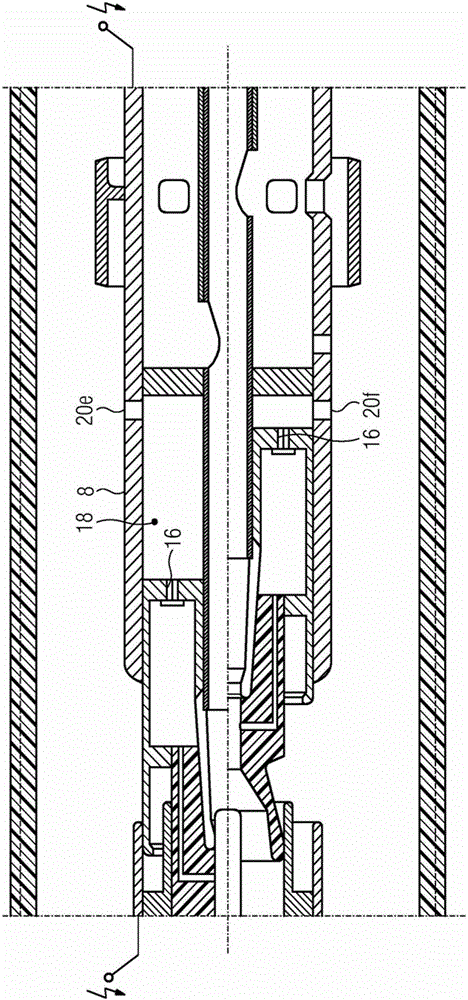

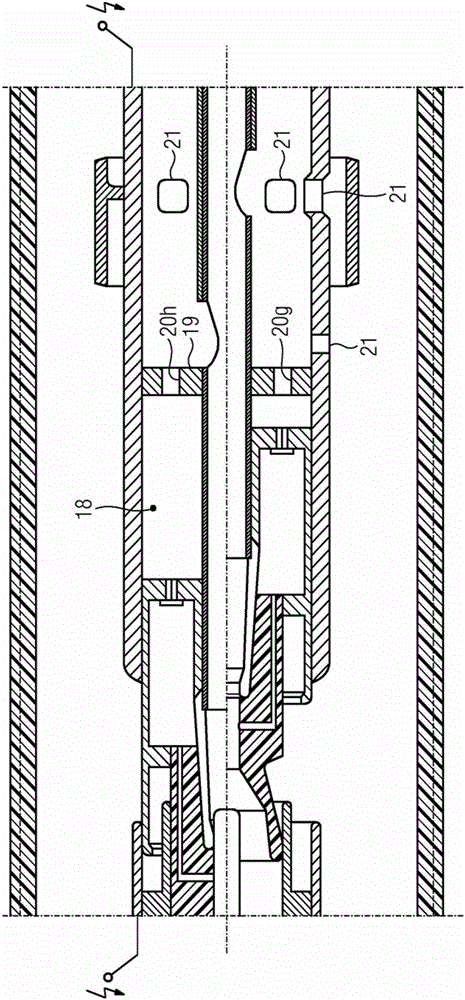

[0037] First, for example for figure 1 , figure 2 and image 3 Explain the construction and mode of operation of compressed gas circuit breakers. here, in figure 1 , figure 2 and image 3 The same reference numerals are used in each of the same type of construction parts, and only for details that differ from each other, alternative reference numerals are used.

[0038] Common to all three figures is that the axis of symmetry 2 divides the figure into a first half and a second half. The drawings each show the switched state of the compressed gas circuit breaker in the first half of the figure and the switched state of the compressed gas circuit breaker in the second half of the figure.

[0039] figure 1 A cross-section of a compressed gas circuit breaker is shown in the cross-sectional view. The compressed gas circuit breaker has an encapsulation housing 1 . The encapsulation housing 1 is here substantially tubular and oriented coaxially to the axis of symmetry 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com