Rotatable cutting tool

A technology of rotating cutters and cutter bodies, applied in the field of improved actuators and rotatable cutters, can solve problems such as operation damage of adjustment devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention will be described with reference to a preferred embodiment shown in the accompanying drawings. Also preferred embodiments explain the features of the invention. It is not the intention of this application to limit the invention to the specific details of the preferred embodiment.

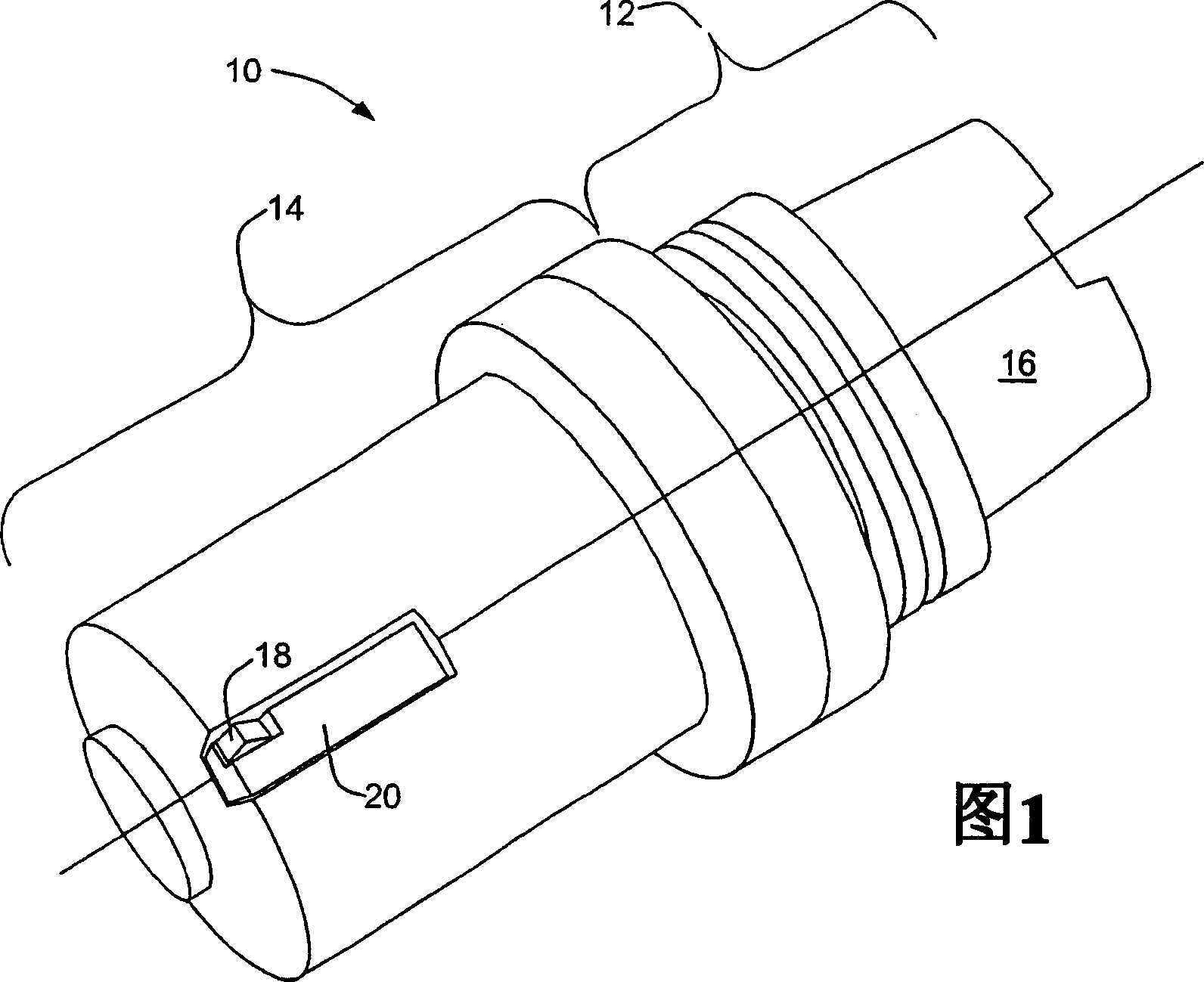

[0013] A rotatable tool 10 shown in FIG. 1 includes a shank portion 12 and a cutting portion 14 . The shank portion 12 is adapted to be mounted on a joint 16 for connection to a tool drive such as a rotatable spindle of a machine tool. The adapter 16 may be adapted to a tool drive spindle of a machine tool lacking an automatic tool change mechanism. Moreover, the joint 16 is preferably consistent with the standard to ensure compatibility with the standard automatic tool changer, such as the well-known standard of this joint: HSK; German Industrial Standard (DIN) International Organization for Standardization (ISO) / Draft International Standard (DIS) 12164-1&-2; American Nation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com