Plate heat exchanger

A technology of plate heat exchangers and heat exchange plates, which is applied in the direction of heat exchanger types, indirect heat exchangers, heat exchanger sealing devices, etc., which can solve the problem that working fluids with unequal flow rates cannot achieve the same flow rate and seal difficulties , Inconvenient disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

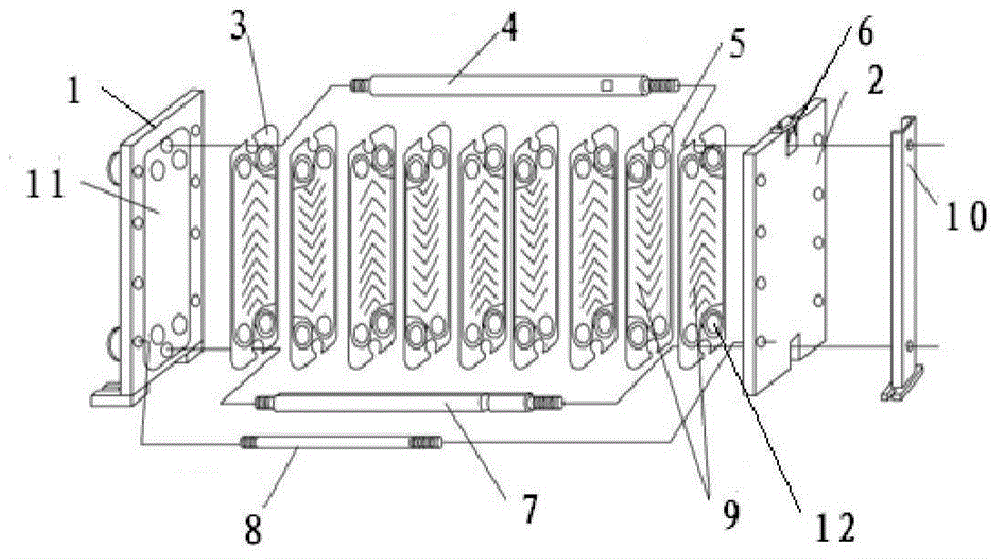

[0017] like figure 1 As shown, a plate heat exchanger is sequentially provided with a fixed clamping plate 1, a movable clamping plate 2 and a pillar 10, and at least two Each of the heat exchange plates 3 is provided with at least one sealing rubber pad 5 and a series of herringbone corrugations 9 .

[0018] Wherein, the heat exchange plate 3 is also provided with four flow channel holes 12, the sealing rubber pad 5 is stuck in the flow channel holes 12, and an upper guide rod 4 is arranged above the sealing rubber pad 5, A lower guide rod 7 is provided below, the two ends of the guide rod are respectively connected to the fixed clamping plate 1 and the movable clamping plate 2, and the lower guide rod 7 is provided with a clamping plate for pressing the fixed clamping plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com