Two-stage blade adjusting mechanism for opposite-rotating axial flow fan

A blade adjustment and adjustment mechanism technology, applied in axial flow pumps, machines/engines, mechanical equipment, etc., can solve problems such as poor synchronization and complex structure, and achieve the effects of compact structure, reduced energy consumption, and reduced ventilation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

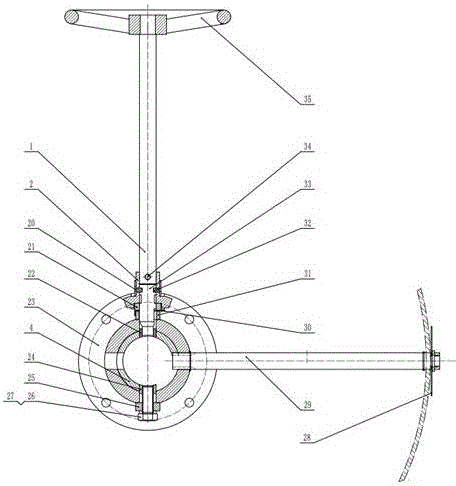

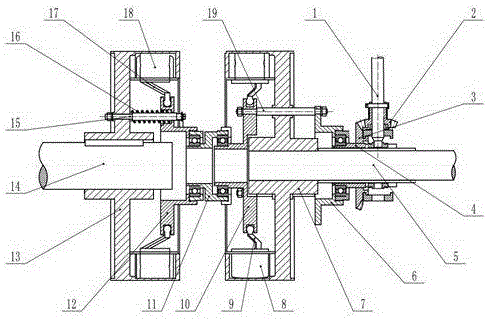

[0017] as attached figure 1 And attached figure 2 As shown, the implementation of the present invention provides a two-stage blade adjustment mechanism for counter-rotating axial flow fans. The adjustment mechanism is coaxially arranged, and the blade adjustment operation shaft 1 is extended to the outside of the fan cylinder for easy adjustment. The specific structure The implementation is that the first bevel gear 2 is fixed on the bottom end of the leaf adjustment operation shaft 1, and the second bevel gear 3 is engaged with the second bevel gear 3, and the second bevel gear 3 is meshed with the split sleeve 4 again, and the first bevel gear 2 and the second bevel gear are engaged again. The rotary motion of the bevel gear 3 is transformed into a linear motion, causing the axial translation disk to generate an axial displacement, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com