Arc-shaped cross frame and round pipe connection quality control method

A technology of connection quality and control method, applied in measurement devices, material magnetic variables, construction, etc., to achieve the effect of reducing workload, ensuring overall stability and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be described below in conjunction with specific embodiments.

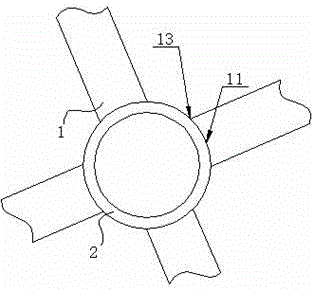

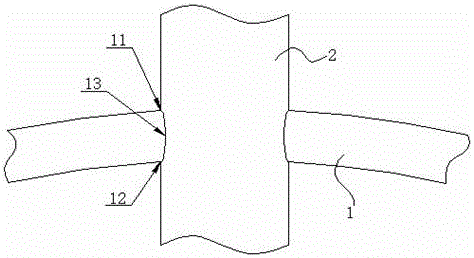

[0016] Such as figure 1 with figure 2 As shown, it is a structural schematic diagram of the connection structure between the arc-shaped cross and the round pipe according to the present invention.

[0017] The arc-shaped cross and round pipe connection structure of the present invention includes four arc-shaped chords 1 and a vertically arranged web 2, and the four arc-shaped chords 1 are arranged around the web 2 and are center-symmetrical On the axis of the web 2, the upper end of each arc chord 1 is connected to the web 2, and the extension line of the arc axis at the upper end of each arc chord 1 is in line with The tangent line at the intersection of the axes of the webs 2 is horizontal, and an intersecting node is provided at the junction of each arc-shaped chord 1 and the webs 2, and each of the intersecting nodes includes a welding toe 11 , a welding edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com