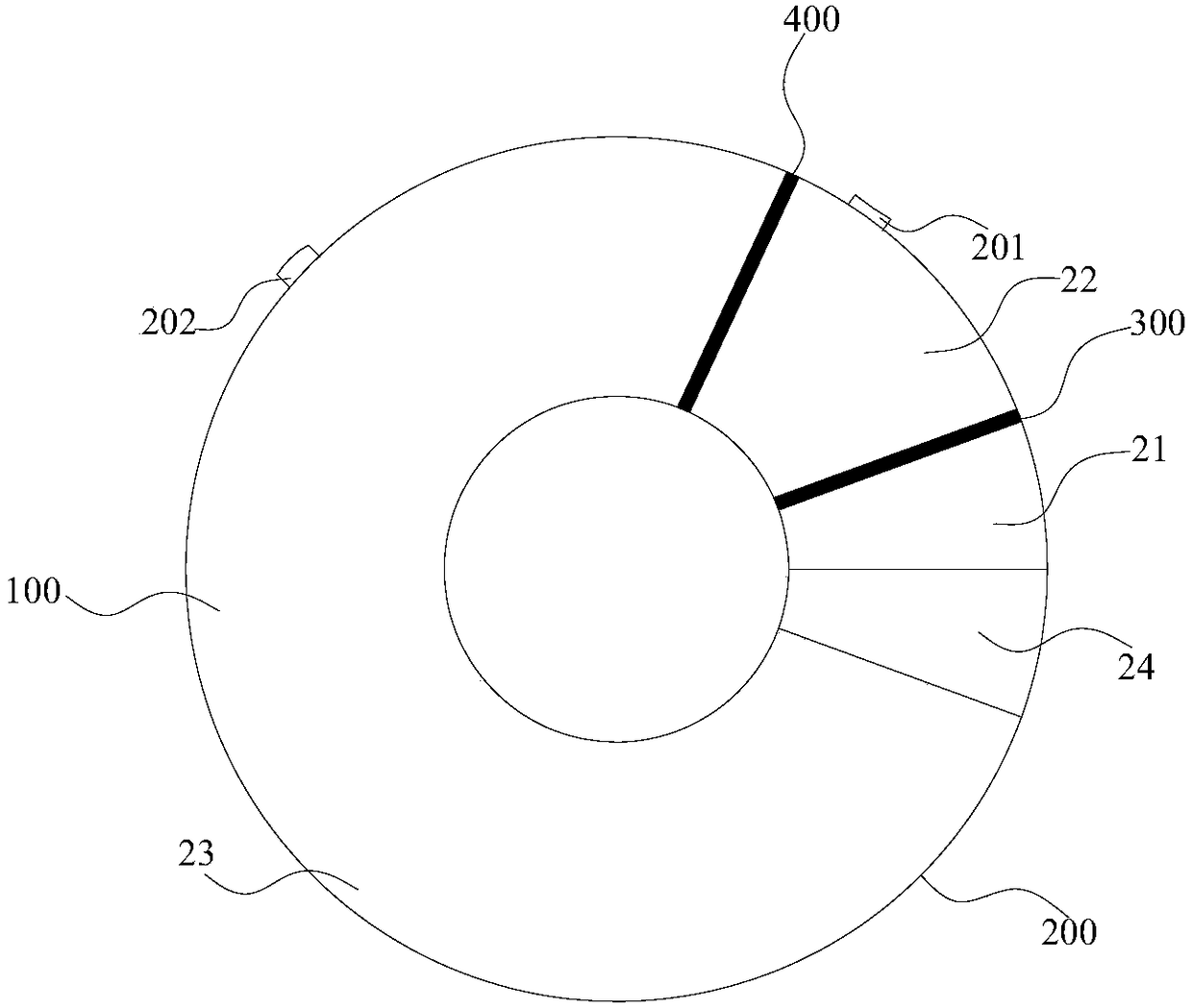

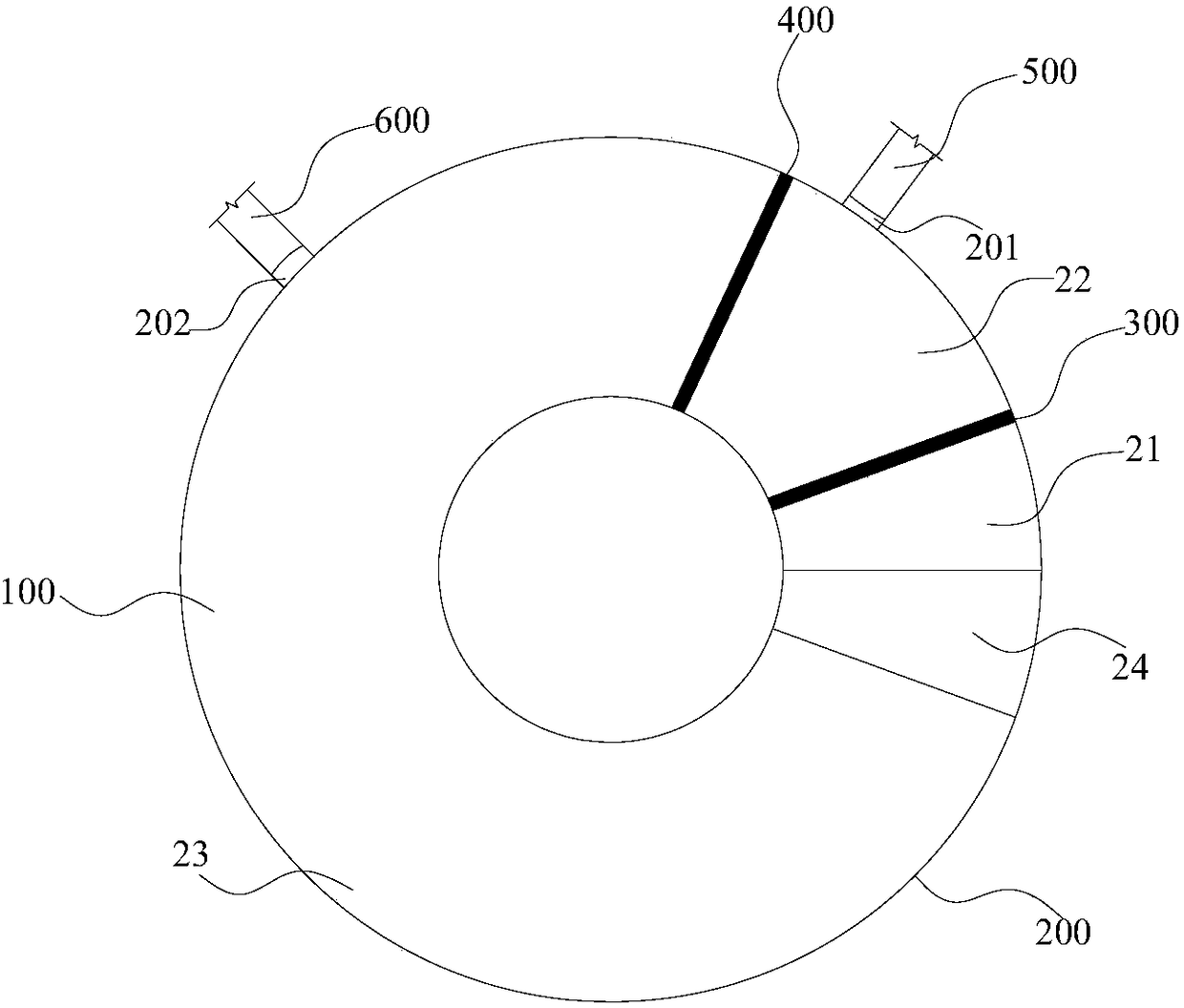

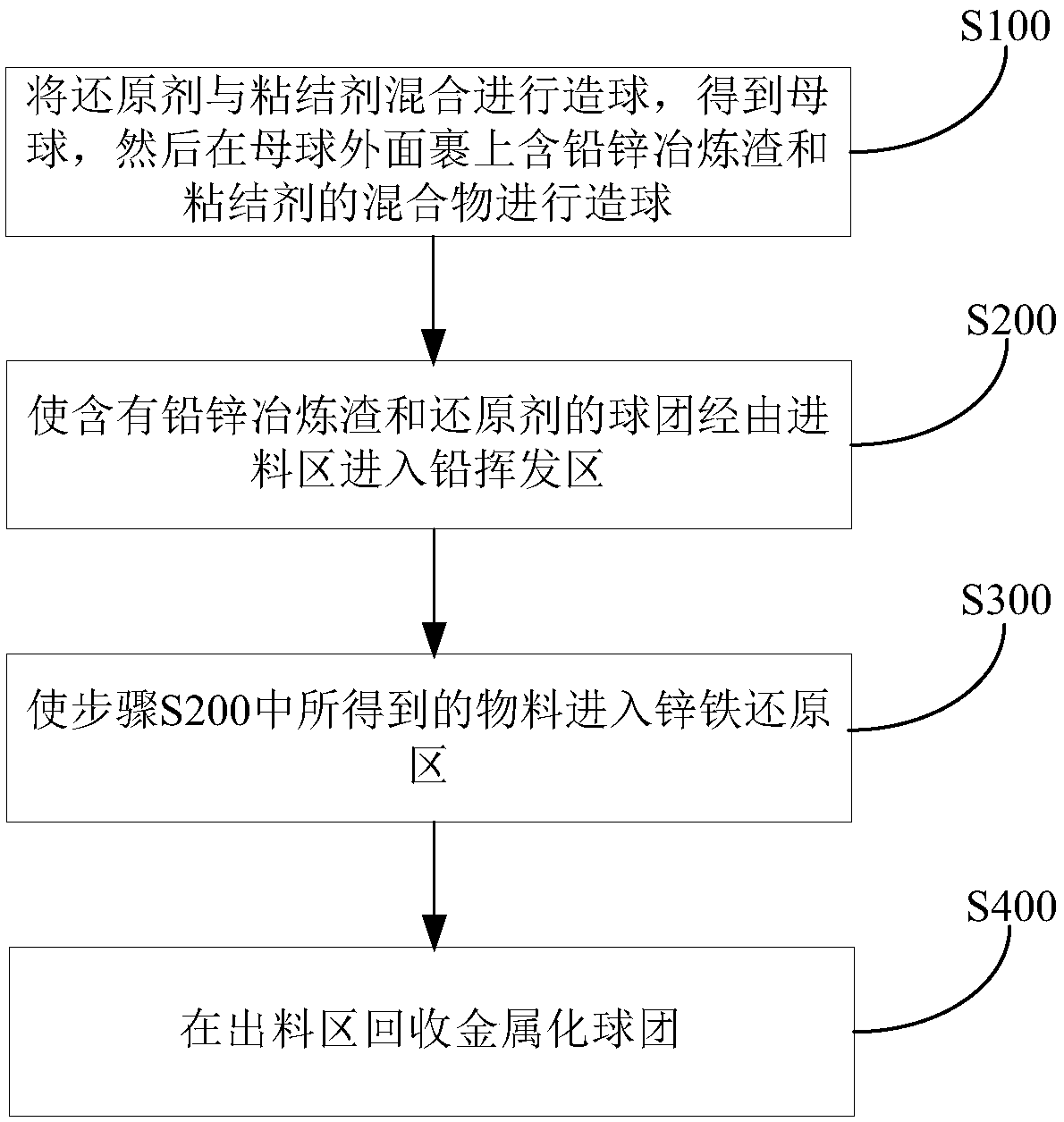

Rotary hearth furnace and method for treating lead-zinc smelting slag

A technology for smelting slag and rotary hearth furnace, applied in the field of metallurgy, can solve the problems of increasing processing procedures and costs, unable to deal with zinc-containing lead dust, not proposing an effective treatment method for one-time separation of zinc and lead, etc., so as to reduce equipment investment costs. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The lead-zinc smelting slag is processed by the rotary hearth furnace for processing lead-zinc smelting slag according to the embodiment of the present invention. The lead-zinc smelting slag is composed of: TFe 35.22wt%, PbO 8.25wt%, ZnO 5.55wt%. After mixing with bentonite in a mass ratio of 100:2, the pellet size is not higher than 5mm. The mixture, in which the lead-zinc smelting slag and the organic binder are uniformly mixed at a mass ratio of 100:5, the final size of the pellets obtained is 10mm, and the pellets are dried and distributed into the rotary hearth furnace, and the temperature in the lead volatilization zone is controlled to be 950℃±20℃, the lead oxide in the pellet is volatilized, and lead oxide dust is collected in the first flue set in the volatilization zone, and the temperature in the zinc-iron reduction zone is controlled to be 1320℃±20℃. On-line monitoring and control is a reducing atmosphere, so that part of zinc oxide in this area is volatiliz...

Embodiment 2

[0078] The lead-zinc smelting slag is processed by the rotary hearth furnace for processing lead-zinc smelting slag according to the embodiment of the present invention, and the lead-zinc smelting slag is composed of: TFe 28.22wt%, PbO 7.25wt%, ZnO 15.55wt%, After mixing with bentonite in a mass ratio of 100:2, the size of the pellet is not higher than 4mm. The mixture, in which the lead-zinc smelting slag and the organic binder are uniformly mixed at a mass ratio of 100:5, the final size of the pellets obtained is 9mm, and the pellets are dried and distributed into the rotary hearth furnace, and the temperature in the lead volatilization zone is controlled to be 950℃±20℃, the lead oxide in the pellet is volatilized, and lead oxide dust is collected in the first flue set in the volatilization zone, and the temperature in the zinc-iron reduction zone is controlled to be 1320℃±20℃, and the temperature in this zone passes On-line monitoring and control is a reducing atmosphere, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com